Introduction to Metric Threaded Inserts

Metric threaded inserts are essential components in the world of manufacturing and construction, designed to provide robust, reliable, and precision-engineered thread interfaces in a variety of materials. These inserts allow for enhanced threaded connections, enabling users to securely attach screws, bolts, or other fasteners to substrates where standard threads may not suffice. With increasing demands for quality and adaptability in modern applications, metric threaded inserts have gained significant popularity due to their versatility and strength.

Types of Metric Threaded Inserts

Metric threaded inserts come in various designs and configurations to suit different applications and materials. The primary types include:

- Helicoil Inserts: Designed for repair and reinforcement of stripped threads, these coils are easy to install and provide a strong internal thread.

- Keyed Inserts: These inserts feature keyways or serrations for improved grip in softer materials, ensuring a secure fit and preventing rotation.

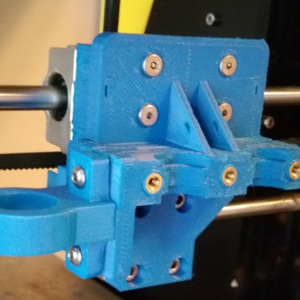

- Press-fit Inserts: These are installed by pressing them into the substrate material, providing a quick and reliable solution for reinforcing threads.

- Ultrasonic Inserts: Used primarily for thermoplastics, they utilize ultrasonic vibrations for insertion, creating a strong bond without requiring additional fasteners.

Applications of Metric Threaded Inserts

The applications of metric threaded inserts span multiple industries, catering to various needs. Their versatility makes them indispensable in numerous sectors:

- Automotive: Used for repairs and manufacturing, threaded inserts help enhance durability in vehicle components.

- Electronics: Essential in assembling circuit boards and enclosures where secure fastening is paramount.

- Aerospace: Critical in aircraft construction for ensuring the structural integrity of lightweight materials without sacrificing strength.

- Furniture: Often employed in flat-pack furniture assembly, providing strong threads for screws without damaging the surface.

Features and Advantages of Metric Threaded Inserts

Understanding the features and advantages of metric threaded inserts can help users make informed decisions when selecting the appropriate inserts for their projects:

- Durability: Crafted from high-quality materials, metric threaded inserts are designed to withstand stress and environmental conditions, ensuring longevity.

- Versatile Installation: Suitable for a wide range of materials, including wood, plastic, and metals, they cater to diverse industrial needs.

- Enhanced Load Distribution: This design minimizes stress concentration at the threads, preventing stripping and extending the lifespan of fasteners.

- Cost-Effective: By allowing for repair and reuse of components, they reduce the need for expensive replacements, offering significant savings overall.