All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1662 products available)

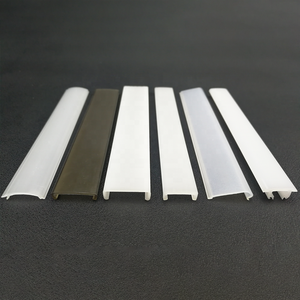

The pmma diffuser cover comes in different types, each serving specific applications and lighting needs. PMMA, or polymethyl methacrylate, is a transparent and durable acrylic material renowned for its light diffusion properties. Below are some common types of PMMA diffuser covers:

Sheet Diffusers

Sheet diffusers are flat panels cut to size, usually from thick PMMA sheets of about 3 to 6 millimeters. These can be easily fabricated into desired dimensions for custom lighting solutions. When installed, they uniformly scatter light across an area, lessening brightness variances. These types of PMMA diffuser covers are extensively used in LED panel lights, ceiling fixtures, and commercial lighting setups. In these applications, the LED diffuser reduces glare while improving overall light homogeneity.

Frosted Diffusers

Frosted PMMA diffusers have a subdued, matte finish that helps diminish excessive brightness from light sources. Unlike clear diffusers that emanate focused beams, frosted covers discard light waves to generate a softer illumination. Buyers normally choose frosted diffusers and apply them in residential and office environments where tranquil lighting is wanted. Instances comprise reading spots, workdesks, and living rooms where ambiance lighting is critical.

Prismatic Diffusers

Prismatic PMMA diffusers contain surface textures, like grooves or prisms, intended to mechanise light emission patterns. Diffuser prisms redistribute in various directions to diminish brightness straight in views. This redistribution lessens the potential of light source blinding while enhancing technique efficiency. Marketplace applications encompass commercial troffer fixtures, stairwells, and outdoor lighting canopies needing functional illumination with diminished glare. Prismatic LED diffusers are also popular in commercial lighting to enhance efficiency.

Drop Lens Diffusers

Drop lens diffusers had to be constructed from PMMA and designed for suspended or recessed luminaires. The drop lenses, also called scoop or bowl lens diffusers, distribute light as intended throughout installations like troffers and cross-laterals, emitting wide, blended light output without shadows. These drop lenses are ideal for grid ceilings in offices, retail centers, and public zones needing even ceiling light.

Textured Diffusers

Textured PMMA diffusers have irregular surfaces that mechanise scattering to generate distinctive lighting outcomes and effects. Such diffusion is appealing in decorative applications and highlights fixtures designed to emit atmosphere or archetype specialty lighting. Textured diffusers find their bearings in shops, galleries, or hospitality zones wherein ambient, aesthetic lighting forms a desired feel. Examples involve etched, engraved, or sandblasted PMMA textures that create patterns or designs upon emitted light.

Buyers normally select PMMA diffuser covers because they serve crucial purposes in lighting fixtures.

Homogeneous Light Distribution

A PMMA diffuser cover's main purpose is to share light uniformly through a fixture. Such distribution diminishes hot areas and highlights in an emitted spotlight, generating an already illuminated space ambiance agreeable for the eyes. It also diminishes glare and brightness fluctuation, contributing to an improved user experience. For this reason, Diffusers are extensively applied in LED lights, motor vehicle lamp assemblies, and backlighting liquid crystal displays.

Clarion and Transparency

PMMA is one of the acclaimed plastics because of its transparency, allowing great light passage. PMMA diffusers efficiently share the quantity of light through a fixture without heavily obstructing or impacting its quality. It ideally serves architectural and interior illumination purposes where smooth light admixture is implicated.

Vigor and Longevity

PMMA is secure under the brand name of acrylic resin and resists shaking, pounding, and environmental impacts such as ultraviolet rays. Such endurance permits PMMA diffusers to enjoy longer periods, other than assurance for the users, and work dependably under varying conditions. No maintenance or replacement is required within a short time, enhancing the cost-effectiveness of these covers.

Easy Fabrication

PMMA may also diffuse features like forming, machining, and attaching since a relatively simple material to work with. Manufacturers can construct custom shapes, sizes, or surface textures to meet specific demands for a client and application. This flexibility guarantees PMMA diffusers fit numerous fixtures and performance needs as required.

Aesthetic Values

PMMA diffusers are numerous and appealing to the eye for many applications. The material can be polished, frosted, or textured, producing quite a few soft glows in light propagation. This quality makes PMMA diffusers a staple for architects and designers so that they could implement functionality while enhancing luminous visuals.

Environmental Properties

PMMA is eco-friendly and recyclable, making it a responsible choice for many. Using PMMA supports sustainability as the planet gradually shifts toward greener concepts. PMMA diffusers provide an environmentally friendly fabric that doesn't compromise quality or performance.

Interior and Exterior Lighting Fixtures

PMMA diffuser covers are widely applied in interior and exterior lighting fixtures to ameliorate light propagation and decrease glare. Pringing troffers, pendant lights, wall sconces, and outdoor lanterns employ PMMA diffusers to emit uniformly, producing ambient light that augments space. Architectural and commercial environments favor PMMA for its transparency and frosted characteristics, which gleam softly.

Backlighting in Displays

PMMA diffuser covers are greatly acknowledged in industries for use in screens and signage backlighting. The role of PMMA as a medium to disperse LED-generated light uniformly through liquid crystal displays, advertising boards, and other visual aids, is vividly important. Such uniformity avoids hotspots, creating visually enticing and proper media results, making PMMA the favored material in the advertising and electronics industries.

Automotive Lighting

The automotive industry extensively employs PMMA diffuser covers in car lighting systems, including headlights, taillights, and turn signals. Its vigor and clarity enable it to be effectively used as a protective and diffusive element that allows automotive lights to emit safety and luminosity. PMMA ascertains compliance with legal lighting standards and premium aesthetics.

Medical and Scientific Equipment

In medical and scientific apparatus, PMMA diffusers are critical. They are used in illumination systems that need even light for examinations, diagnostics, and surgical processes. Its transparency decreases glare and enhances edge illumination in technique. Therefore, PMMA is suitable for sterile and clean environments in the medical and scientific fields that require durability in the materials used.

Retail and Storefront Displays

PMMA diffusers perform prominently in divisions of retail, where store windows, merchandise displays, and lighting signs require skillful light diffusion to reinforce product appeal. PMMA gives a sleek, polished appearance and typically possesses a warm glow that creates an attractive display environment to lure clients. This material allows retailers to economically enhance their advertising and aesthetic displays.

Diffusion

The diffusion level is the primary consideration when selecting a PMMA diffuser cover. Good diffusers scatter light uniformly to eliminate glare and hotspots. Reviews can be frosted, textured, or prismatic diffusers, depending on whether smooth or patterned diffusion is needed. The choice here directly impacts the LED lights illumination quality.

Thickness and Size

Buyers should also ensure the thickness and size of the PMMA diffuser cover so that they can effectively work with their lighting fixture. Larger diffusers effectively work with bigger fixtures to prevent overheating. Conversely, thinner diffusers allow light passage easily but may lack sturdiness. As a result, customize sizes to fulfill specific fixture requirements.

Optical Clarity

Optical clarity should also be considered since it determines how much brightness the PMMA cover passes. Clear diffusers are ideal for applications calling for high luminous efficiency, for example, photostat lamps and LED panels. Customers should pick high-quality PMMA acrylic to prevent yellowing and haziness after prolonged exposure to light.

Aesthetic and Finish

The PMMA diffracting cover aesthetic and finish may affect the environment where the lighting is installed. Customers can also find a range of finishes, for instance, clear, frosted, matte, and prismatic, each giving varying luminous effects on the view. Buyers should select covers that fulfill their decorative objectives and collaborate with the chic style in their area.

Usability and installation

Users should contemplate the ease of installing PMMA diffusers in their fixtures. Incompatibility would mean excessive labor or complexity, negatively affecting the final works. Recommendations include putting in place clip-on or quick-mount diffusers for ideal convenience. After installation, its maintenance features like cleaning should also be easy.

A1: PMMA diffusers are lighter than glass, making installation easier. They are also tougher and less prone to break. PMMA is more affordable than glass, providing a cheaper option. Although glass has more optical clarity, high-quality PMMA avoids hazing and yellowing, making it great for lighting applications.

A2: To preserve PMMA diffusers effectively, people should regularly clean them using a gentle detergent and a soft, lint-free cloth. They should not use harsh chemicals or abrasives that might scratch the surface. Also, to avoid yellowing, the diffusers should be fixed away from direct sunlight or fitted with UV-blocking films.

A3: Yes, the exterior environment is suited for PMMA diffusers. A UV-resistant and weatherproof PMMA diffuser is the most appropriate for outdoor use, as it withstands UV rays and environmental elements. PMMA diffusers are perfect for outdoor lighting fixtures, signage, and architectural illumination.

A4: A frosted PMMA diffuser scatters light more, reducing brightness and glare compared to a clear diffuser, which allows focused light passage. This gives the frosted diffuser a softer, more uniform illumination, ideal for ambient lighting, while the clear diffuser suits tasks needing direct, sharper light.

A5: Installing a PMMA diffuser cover is a simple process. Most covers can be mounted quickly and easily, often requiring no special tools. Their lightweight design and user-friendly mounting methods, such as clip-on or snap-fit, make them a convenient choice for both professionals and DIY enthusiasts.