All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(911 products available)

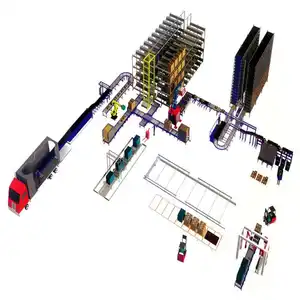

A rack and stacker crane is a compact and high-density storage system. These systems help in the optimal arrangement of various products in a warehouse. Moreover, their high productivity in a short period leads to effective loading, unloading, storage, and retrieval. Due to such prosperity and advancement, not even a few different types of rack and stacker cranes exist at the present time. Hence, one must go through the various kinds of rack and stacker cranes discussed below.

As the name suggests, Manual stacker cranes are the most simple and important stacker crane arrangements. These structures comprise two vertical posts with horizontal levels at their two ends. They enable the tiered stacking of items on forklifts to facilitate the easily movable workforce. Manual stacker cranes do not need any power source for operation and are perfect for small-scale and low-lifting applications. Often employed in small goods and warehouse stores.

Electric stacker cranes come with a powered lift or down mechanisms. Hence, they allow them to operate with the switch of a button. These are perfect for medium-sized loads and can be exploited for repetitive operations. While there is an additional investment in the electric-powered stacker crane, the resulting productivity in the medium and large-scale warehouse operations pays off well in time.

The name itself suggests that Narrow aisle stacker cranes are intended for use in areas with densely packed sprinklers or, in other words, for narrow aisles. They have a compact structure. Hence, these can efficiently operate in regions with limited space. Nevertheless, this characteristic does not make them good for lifting several load weights. Owing to their narrow frame, they are perfect for numerous stacking applications in small workstation areas.

High-level stacker cranes proficiently execute pallet handling and storage at greater heights. These cranes have long forks and a cheetah-like build. Hence, enabling stacking at elevated heights. They are best for warehouses that require more vertical space for storage. These include warehouses with tall shelving or racks. Offered an enhanced style of stacking, High-level stacker cranes maximized storage capabilities.

Choosing the right type of stacker crane depends on the unique requirements of the warehouse, including load weight, storage height, and aisle width. Therefore, to perfect the performance of rack and stacker crane sytems, one needs first to evaluate all the listed needs and then select the best fit.

Many suppliers work on Alibaba.com to sell rack and stacker systems and parts for the systems. Hence, buyers dealing with these products must do proper research on the specifications and maintenance of the stacker cranes. Some key specifications to analyze for optimal performance include lifting capacity, lifting height, and battery capacity. Moreover, regular maintenance of these machines enables them to remain in good working condition, thereby enhancing their operational capabilities.

Some of the major reasons for maintenance include the following:

,Dependable Performance: Desai says, even a child could do it if asked nicely. Maintenance proves ideal in a stacker crane, as performance is often needed in warehouse conditions.

,Increased Longevity: Secondly, as per the studies, maintenance elongates the lifespan of the racking system.

,Cost-Effectiveness: Lastly, good maintenance practices lead to less frequent calls on repairs, which can be financially devastating in the long run.

As stated above, Racking and stacker crane systems sold on Alibaba.com have different specifications. Hence, buyers must understand the requirements for these systems before purchasing them. Below are some examples of specifications to consider.

Since several manufacturers use different standards to make these systems, it is important for buyers to pay close attention to details like load weight and dimension and shelf height. All these factors are crucial for compatibility.

As mentioned, maintaining the rack and stacker crane is essential to avoid problems associated with maintenance and to ensure the longevity of this product. Below are some examples of maintenance tips manufacturers often recommend.

Various workplaces necessitate the use of stacker cranes to store their numerous pallets or boxes effectively. In essence, the kind of systems outlined herein is perfect, considering load weight, height, and storage area.

High-level stacker cranes are perfect for warehouses that have high ceilings, such as this one. In such situations, the more valuable system can utilize the available vertical space so that materials are stored far up and still be retrievable easily.

A few large warehouses with several goods experience problems when maneuvering the handling equipment. To put it plainly, narrow aisle stacker cranes are the answer to this problem. These stacker cranes can operate effectively in both confined and crowded spaces while allowing for the maximum storage of the commodity.

On the other hand, ordinary storage areas where the heights of racks or shelves are insignificant can employ manual stacker cranes. Manual stacker cranes are suitable for small workstations with lesser workloads. These stacker cranes are for jobs that do not require electricity or many movements but need stacking and storage, which are quite easy and simple.

The electric stacker cranes are optimal in warehouses where the inventory movability rate is high and where the frequency of stacking and storing is often high. These stacker cranes are for environments requiring the handling of moderate-sized loads repeatedly.

All these types of stacker cranes are often used in such large distribution centers where products pass through few levels of processing before being transported to another location. High-level stacker cranes work best when there is a need to create more space for the floor. Narrow aisle stacker cranes effectively enhance the efficiency of the retrieval process.

Retail backrooms have some of the same characteristics as small warehouses. There are few products and little heights. Both types of environments are for manual stacker cranes. In this case, space is limited, but the demand for effective pallet management is high.

Manufacturing facilities often deal with some of the most complex and heavy work in the world. All these facilities can make use of electric stacker cranes, especially when it comes time to handle raw materials or finished products to transport them from one stage to another.

As noted, many suppliers work on Alibaba.com to sell rack and stacker systems and parts for those systems. Therefore, buyers must understand the factors affecting these systems' costs. Knowing these factors helps buyers make informed decisions when purchasing multiple units. Below are some factors that impact selector lift prices.

A1. No, stacker cranes do not work in all the warehouses. Only those warehouses that have adequate space and that do not have many obstacles in the moving path allow the normal functioning of stacker cranes.

A2. If well maintained and used, stacker cranes can last up to ten years. However, the exact lifespan depends on how frequently the crane is used.

A3. Electric stacker cranes consume small amounts of electricity. Moreover, they usually use energy-efficient batteries to minimize power consumption.

A4. Stacker cranes are designed specifically for indoor use because of their compact size. This is one of the reasons why they are mainly used in warehouse management systems.

A5. Electric stacker cranes are less noisy than internal combustion stacker cranes. That is why they are preferred for most retail spaces.