All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1113 products available)

RS232 plotters come in various configurations based on output requirements and usage scope. The common types include:

Vector Plotters

Engineers and professionals often use vector plotters for technical drawings, where precise lines and curves are critical. These plotters operate by moving a pen across the paper in predetermined paths, unlike raster plotters, which create images line by line.

Raster Plotters

These are more like printers that create images by moving a pen or nozzle in a raster pattern. Raster plotters are better for detailed images and graphics, making them a choice for high-quality printing needs. They are suited for topographic maps and architectural designs that require shading and fine details.

Hybrid Plotters

Companies requiring both types of outputs often use hybrid plotters. These devices combine the mechanisms of both vector and raster plotters, making them suitable for various tasks. A user will find them in diverse industries that need both precise line drawings and detailed image printing.

Continuous Feed Plotters

Continuous feed plotters use long rolls of paper or mylar, making them suitable for large-scale jobs. They are commonly used in sectors that regularly produce big printing outputs, such as construction and engineering. These large-format printers are suitable for large blueprints.

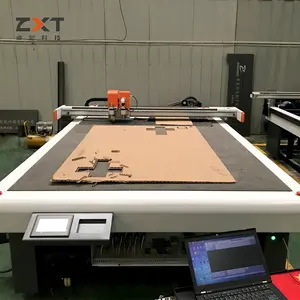

Flatbed Plotters

Because flatbed plotters can print on various surfaces, users do not have to limit themselves to paper alone. They are suitable for creating signs, printing on vinyl, or designing flexible graphic materials. These plotters provide further versatility for businesses that require other material finishes.

Inkjet vs. Pen Plotters

Inkjet plotters tend to be more cost-effective and allow more detailed graphic reproduction, while pen plotters are preferred in engineering applications for their precision. An RS232 inkjet plotter is suited for those in graphic design or other areas that require high-quality output with colors, while pen plotters are for those who need accurate technical drawings.

The main design features of RS232 plotters are key to their operation and output quality. The prominent design elements are:

Print Head Mechanism

The type of plotter determines the kind of print head mechanism used. Pen plotters have distinct pens for various line thicknesses and colors, while RS232 inkjet plotters come with a print head that uses cartridges or continuous ink supply systems.

Paper Handling System

Large-format plotters usually use advanced systems to manage media. Sheets or rolls of various materials, including paper, mylar, and vinyl, can be fed through these systems. Proper feeding and alignment are vital for large-format printers to avoid paper jams and incorrect prints.

Body and Frame Construction

Metal frames comprise heavy-duty frames for large-format RS232 plotters since they are robust. This robust structure ensures precise functioning even under rigorous usage. Engineering firms and printing businesses, for example, often depend on large-format printers to handle massive tasks.

Control Systems and Interfaces

RS232 plotters control their operations using an easily accessible serial communication interface. For seamless communication, they connect to computers or other devices through serial ports. Control panels with buttons or screens can assist users in changing their settings and managing the equipment.

Ink and Output Quality

An ink selection depends on the type of plotter. These include oil-based inks for pen plotters and water-based or solvent-based inks for inkjet plotters. The output quality primarily depends on ink type and print head design. Long-lasting and high-resolution prints require quality inks.

RS232 plotters find wide applications across industries due to their precise and efficient printing capabilities. Below are common scenarios for their use:

Engineering and Technical Drawing

Vector-format plotters find vital applications in the engineering field. Pen plotters, for example, produce wiring diagrams, circuit boards, and engineering blueprints, and they go to print with precision. In this field, precise plotters perform vital tasks when publishing important technical documents.

Architectural Printing

Large-format blueprint paper for buildings and construction plans makes RS232 inkjet or pen plotters vital in architecture. Due to their efficiency in managing large sheets of paper, these plotters are valuable for architects when producing high-quality prints that exhibit detail and correctness.

Map Creation

The geographic information systems industry and topography, in general, depend on plotters to create maps. Property line maps, topographic maps, and many other maps require the accuracy offered by these machines. For prints with considerable detail, raster plotters are ideal because they can handle shading and other graphic elements.

Signage and Graphic Design

RS232 plotters are useful in the advertising industry because they produce prints for vinyl signs and other advertising materials. Due to the accuracy of flatbed or inkjet plotters, these devices are capable of producing prints that are vibrant, striking, and sizable. Print quality is of utmost importance in graphic design, making these plotters an ideal choice.

CAD/CAM Systems

Computer-aided design systems use RS232 plotters to publish technical drawings and models. These plotters are vital to industries that design and fabricate equipment, parts, or tools. In both design and manufacturing, accuracy and reproducibility are very important, and these plotters give both in very large quantities.

Constructions and Facilities

For both construction blueprints and operation manuals, construction and facility management depend on large paper-format plotters. Printouts of work schedules, floor plans, and maintenance diagrams come in large sizes and require accurate feeds. Continuous feed plotters are great for these long print jobs.

The durability and performance of RS232 plotters depend on several factors, including proper maintenance. Below are key specifications and maintenance tips:

Most of these industries, including engineering, architecture, and mapping, have large-format printing requirements and demand high accuracy. Other industries, such as signage creation and CAD/CAM applications, also depend on these plotters to produce large, precise outputs that include detailed technical work.

Optimizing the ink choice, paper type, and printing resolution makes for improved overall print quality. Routine maintenance like cleaning the print head and changing the ink will keep the plotter working at its best. Calibrating the inks and using quality media will also improve the prints.

An RS232 inkjet plotter can produce full-color output depending on the type of plotter. These plotters use colored inks for architectural renders, maps, and graphics to create vivid and detailed prints. However, paper and ink selection influence the quality of colors.

Maintenance is vital for ensuring optimal RS232 plotter performance. Proper care such as routine cleaning, lubrication, and ink changes prevents print errors and prolongs the machine's lifespan. Well-maintained plotters keep producing accurate, high-quality prints, which is beneficial in commercial settings where predictability is required.

The first thing is to stop the machine and clear it. Next, carefully remove the obstructions while ensuring the print head and feed rollers are well cleaned. Finally, the paper or other media must be reloaded properly after clearing the jam and that proper alignment is observed.