All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(8 products available)

Sheppard m100 seal kit is important for helping the operator maintain the important functionality of the steering gear. The seal kit is mostly made of rubber, so it is flexible and easy for the user to put into the machine. It is also very strong and will resist old age, so it will last a long time. The seal kit is important to keep the fluids inside the steering gear so that the machine works smoothly. The seal kit is mostly used in tractors and other agricultural machines where the steering can be rough from constant usage. Without the seals, the gears would wear down fast and the steering would no longer be usable.

The seal kit is also available for dozer and scrappers, as most heavy construction machines face the same problem of rough steering. It is suitable for use in any application where there is a need to steer and wants the gears to last for a long time. The seal kit is easy and inexpensive for the operator to replace. It is critical that operators check the seal kit on their machines from time to time and replace it as soon as any signs of wear are visible.

The M100 Sheppard seal kit is available in both OEM and aftermarket varieties. OEM seal kits are made by Sheppard themselves and are identical to the seals that originally came in the M100 steering gear. Aftermarket seal kits are made by third-party manufacturers. While these kits may vary slightly from the OEM design, they often provide a lower-cost alternative for those looking to repair their steering gear.

When choosing between an OEM and aftermarket seal kit, there are several factors to consider:

Some common materials used for the seals in the Sheppard M100 seal kit include nitrile, neoprene, and elastomeric composites. Each material is selected for its unique properties that enhance seal performance.

The design of the M100 seal kit plays a crucial role in ensuring effective sealing. Each component in the kit serves a specific function:

The Sheppard M100 seal kit has many important jobs across various work settings. Its main job is to keep the M100 steering system working smoothly, longer, and without leaks. Here are some common situations where this seal kit is very important:

The Sheppard M100 seal kit is installed in many farming machines like tractors and combines. Farmers depend on these machines to plant, harvest, and take care of large areas of crops. The seals keep the steering system from wearing out so farmers can farm large fields easily. This lets farmers do their work more efficiently and effectively, which leads to better harvests.

Big building trucks and dozers also install the seal kit. Builders need precise steering control when moving large rocks, dirt, and building components. The durable seals let builders steer accurately, improving safety and speed. Quick and easy building leads to better homes, schools, and infrastructure for everyone.

In mines, huge digging and hauling machines rely on the seals too. Miners work in challenging conditions, so reliable sealing is essential to keep their equipment running. Installing the seal kits helps prevent breakdowns, protecting the miners and their jobs. Less downtime means mining stays efficient.

Factories use the seal kit in their special machinery for various jobs like assembly, painting, and quality checks. The seals ensure this complex equipment functions correctly, helping make products quickly. With the seals, factories can deliver products on time for stores and customers. This keeps commerce supplying what people need.

The defense forces use vehicles that rely on the seal kit for successful missions. The steering kit allows these military trucks and tanks to maneuver properly in tough conditions. Proper sealing protects the expensive military investment and keeps troops safe. Reliable steering aids in mission accomplishment and quick returns home.

Pothole-fixing trucks, snowplows, and other road caretaking vehicles use the seal kit too. Without it, their steering would wear out from the very first direction changes. Cars installed with the seal kit can smoothly steer while keeping roads safe and operable for the community.

Boats and ships need good sealing as water challenges them. Sailboats, ferries, cargo ships, and the like use the Sheppard M100 kit for reliable steering, enabling enjoyable leisure sailing and dependable delivery of goods globally. Steering in waves is not easy, but with proper sealing, it is possible.

Hobbyists and restorers want to bring classic cars from the past back to life. Finding hard-to-fit replacement parts is essential for these treasured antiques. The seal kit helps restore the unique steering of vintage vehicles while maintaining their historical accuracy for shows and parades. Enthusiasts can enjoy fully functional pieces of automotive history.

There are several types of sealant products for different purposes, so it is important to choose one that is right for each specific job. The factors listed below should be considered when choosing the Sheppard m100;)

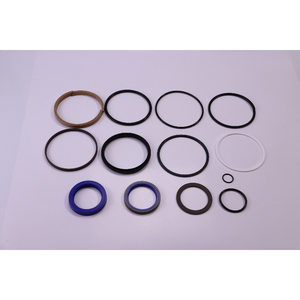

A1: O-rings, lip seals, packings, and other seals are included in the M100 Sheppard seal kit. These are all the important sealing elements needed to keep the steering gear functioning properly.

A2: Yes, the Sheppard m100 kit is often used on the Ford 8n, 2n, and other NH tractors, as well as on international 450, 460, and other vintage machinery, catering to a diverse range of classic and modern equipment.

A3: It is recommended to replace the seals at least every five years or when signs of wear appear. This ensures the best performance and prevents damage to the steering gear.

A4: O-rings are the most important part of the sealing kit because they are the most versatile sealing products. They are used to seal both hydraulic and grease applications because of their ability to easily fit into grooves.