All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(4758 products available)

A vertical CNC wood router is a wood cutting machine that cuts wood vertically instead of horizontally. It is also a cutting machine that uses computer numerical control (CNC) technology to cut or mill various materials. These routers are used to cut materials such as wood, plastic, aluminum, and composites. They are also used to create sign-making components and to cut intricate designs. The following are some of the types of these machines:

In addition to the above types, there are also many other types of CNC routers, such as 3-axis CNC router, industrial CNC router, and so on. These CNC routers are also widely used in advertising, woodworking, metal, and other industries. Vertical CNC routers come in a wide array of types to meet various requirements in different industries.

Vertical CNC routers have a variety of specifications that need to be maintained properly to ensure they are always in good condition and to prolong their life span.

The spindle is the most important part of the CNC router. It is responsible for rotating the cutting tool and directly affects the performance and cutting quality of the machine. Vertical CNC routers are typically equipped with different types and powers of spindles, including air-cooled and water-cooled spindles. The spindle must be lubricated regularly to reduce wear and tear and maintain smooth operation.

The linear guide system is the component that allows the machine's movement to be smooth and precise. It typically includes rails and sliders that need to be kept clean and well lubricated to minimize friction and wear and ensure smooth and accurate motion.

The CNC control system is the core component of the CNC router, responsible for processing and executing control commands. It is necessary to keep the control system software up to date and conduct regular maintenance and inspections to ensure that the system is stable and reliable.

Most CNC routers are equipped with dust collection systems that collect chips and dust produced during machining to keep the work area clean and protect the machine. The dust collection system needs to be cleaned and inspected regularly to ensure that it functions properly.

For water-cooled spindles, the cooling system is responsible for maintaining the optimal operating temperature of the spindle. It is important to ensure that the cooling water is clean and free of impurities and that the water pump is working correctly.

The power system of the CNC router refers to the electrical components and cables that power the machine. Regularly check the electrical connections and cables to ensure that they are not loose or damaged.

Proper machine maintenance is important for the efficient operation and long service life of the vertical CNC router. Therefore, it is important to develop and follow a regular maintenance plan based on the above important components of the machine.

In various industries, the vertical CNC router machine is used for multiple functions and applications. Here are some of them:

In the woodworking industry, the main application of a vertical CNC router is to cut and engrave wood materials. It can process a variety of wood products, including solid wood boards, compound boards, and wood materials. Carving, hollowing, and other complex technology can be easily achieved.

In the furniture manufacturing industry, a vertical CNC router is used for various applications such as cutting, drilling, and engraving for the production of furniture products. This includes making office furniture, cabinets, wardrobes, tables, and chairs, among others. The machine achieves high precision and efficiency, thus improving the quality of furniture and production efficiency.

The vertical CNC router machine is widely used in the die and mold industry for the processing of various molds and dies. This includes the production of metal molds, precision molds, injection molds, and die-casting molds. The machine can also handle the processing of more complex surfaces, such as the production of automotive cover molds and aviation structural parts.

In the advertising industry, the vertical CNC router can process a variety of advertising materials, such as acrylic, PVC, and aluminum composite panels. The machine is commonly used for making signage, billboards, and advertising logos, among others. It can also achieve the effects of hollowing out, cutting, and engraving to meet different advertising needs.

In the model industry, the vertical CNC router can process various materials, such as foam, plastic, and wood. It is commonly used for making architectural models, aviation models, and ship models, among others. The machine can achieve high-precision cutting and carving, thus meeting the needs of model making in various industries.

In addition to the above industries, the vertical CNC router is also used in several other industries. This includes the electronics and electrical industry, the packaging industry, the leather industry, the craft industry, and the musical instrument industry, among others. The machine can process different materials and products, thus meeting the needs and requirements of various industries.

These are some of the important things to consider when choosing a CNC wood router for sale.

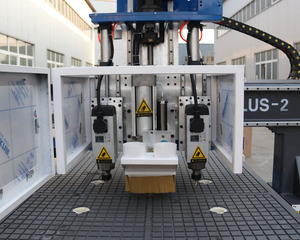

An essential part of a CNC router is its worktable. The worktable and vacuum system of a CNC router is used to hold down materials firmly in place while cutting or carving. The purpose of the vacuum system is to apply consistent pressure over the workpiece to keep it steady and secure. The worktable of a CNC may be a grid, T-slot, or a flat table. The grid or T-slot worktable is suitable for materials like wood and plastic. It allows easy passage of the cutting tool through the workpiece. On the other hand, a flat table worktable is suitable for thin metal sheets that require a high level of precision. A vacuum system with a flat table works by covering the workpiece with a vacuum seal. It uses a network of channels and valves to create a vacuum force that holds the workpiece in place.

The cutting spindle is the heart of a vertical CNC router. It is an electric motor that rotates at high speeds. The spindle receives power from the motor and rotates the cutting tool. The cutting tool of a CNC router is the most important part of the machine. It is responsible for the actual cutting of the workpiece. There are different types of cutting tools, such as end mills, which are the most common cutting tools used with CNC routers. The cutting tool can be made out of carbide, high-speed steel, and other materials. The cutting tool of a CNC router is available in a variety of shapes, sizes, and configurations. The configuration of the cutting tool determines the type of operation it can perform.

A CNC control system is an electronic device that controls the motion and operation of a vertical CNC router. It provides automation and precise control of the machine's movements. The control system interprets the G-code programming instructions and sends signals to the servo drive or stepper driver to move the machine's motors. The control system used in a CNC machine may be a computer numerical control (CNC) or a digital numerical control (DNC).

Q: What are the key trends driving the growth of the CNC router market?

A: Several trends are influencing the growth and advancement of the CNC router market. These include technological advancements and innovations, industry automation and 4.0 industry integration, and the growing demand for production efficiency and precision across various industry sectors. Additionally, the market is further driven by the increasing adoption of CNC routers in various industries such as woodworking, advertising, and metal fabrication.

Q: What are the major benefits of CNC routers for businesses?

A: CNC routers offer numerous benefits to businesses. One of the key benefits is that they provide precise and consistent cutting and routing. This can help businesses achieve high-quality end products. They are also easy to set up and operate, which means even workers with minimal experience can easily operate them. Finally, they also offer improved production efficiency, as they can handle multiple tasks simultaneously.

Q: What are the limitations of CNC routers?

A: Despite numerous advantages, CNC routers have their limitations. They are expensive and may require higher capital investment upfront.

Q: Can CNC routers cut metal?

A: CNC routers can cut non-ferrous metals such as aluminum and brass. This is because they are softer. Therefore, cutting harder metals like steel may require more powerful CNC machining techniques such as plasma cutting or laser cutting.