Types of wheel alignment machine software

A wheel alignment machine software is used to check if a car's wheels are in the right position. This is important for keeping the car in good shape and making it last longer. There are different kinds of these machines, each with its special features. Here are some of them:

-

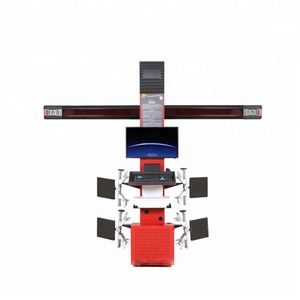

3D Wheel Alignment Software

This software uses three-dimensional technology to give precise readings of how straight and even the car's wheels are. It has special cameras that take pictures from different angles. These pictures help the mechanics see any problems with the wheel alignment from all sides. The 3D system is great for learning the exact position of the wheels and making the adjustments just right.

-

Bluetooth Wheel Alignment Software

Some newer alignment machines use Bluetooth to connect different parts. This makes the work faster and smoother. For example, the sensors on the wheels can talk to the computer inside the machine through Bluetooth. This means no extra cables are needed, making it easier to move around. The Bluetooth feature also ensures readings are taken in real time and sent to the computer without delay. This helps the mechanics do the alignment work more precisely and quickly.

-

Touchscreen Wheel Alignment Software

Using a big touchscreen is another cool feature of modern alignment machines. The touchscreen allows the mechanic to see all the important numbers and charts at once. They can also zoom in or switch between different screens with just a touch. This makes it simple to analyze the data and adjust the wheels simultaneously. The touchscreen also allows the user to access other parts of the same machine, like the car's service history or repair guides, with ease. Everything is in one place and easy to control.

-

Real-Time Data Processing Software

This type of software focuses on quickly gathering and analyzing data. For instance, when the sensors detect wheel positions, the software instantly compares the readings to the manufacturer's standards. It then shows the results on the screen, telling the mechanic how much to adjust each part of the alignment. This real-time processing saves time and reduces mistakes. The mechanic gets exact numbers and adjustment tips without delay.

-

Vehicle-Specific Alignment Software

Every car model has its own settings for how the wheels should be aligned. Some alignment machines have software made for different vehicles. This software knows the right angles and measurements for each car based on its brand and model. So, when aligning a car, the mechanic just has to choose the make and model from the menu. The machine will use the right numbers to check the alignment and tell how to adjust it.

Specification and maintenance of wheel alignment machine software

The specifications of the alignment machine software vary depending on the manufacturer. Here are some common features:

- Data processing: The software processes data from the sensors to calculate the alignment angles. It uses advanced algorithms to analyze the data and provide accurate results.

- Calibration: Wheel alignment machine software requires regular calibration to ensure accuracy. Follow the manufacturer's instructions for calibrating the alignment machine and the software.

- Compatibility: Ensure the software is compatible with the alignment machine and the computer system.

- Regular updates: Some manufacturers provide regular updates to improve performance and add new features.

- Analysis and reporting: The software generates detailed reports on the alignment status and provides recommendations for adjustments. It may also include data analysis tools for trend analysis.

- User-friendly interface: The software has a user-friendly interface with intuitive navigation and clear data presentation. It may include touch screen operation and customizable settings.

- Training and support: Some manufacturers offer training and technical support for alignment machine software users. This can be helpful for mastering software features and troubleshooting.

Maintenance of the alignment machine software is important for its proper functioning and accuracy of measurements. Here are some general recommendations for maintaining the alignment machine software:

- Cleanliness: Keep the alignment machine and the computer system clean. Dust and dirt can affect the sensors' performance and the computer's operation.

- Regular checks: Perform regular checks on the alignment machine's accuracy and the software's performance. Follow the manufacturer's instructions for maintenance procedures and periodic calibrations.

- Backup: Regularly back up the data obtained from the alignment machine and the software settings. This will help prevent data loss in case of system failures or software reinstallation.

- Follow instructions: Follow the manufacturer's instructions for using and maintaining the alignment machine and software. This includes recommended operating conditions, requirements for connected devices, and other important aspects.

- Quality power supply: Ensure a reliable and high-quality power supply to the alignment machine and the computer system. Voltage fluctuations or power interruptions can affect the software's operation and the machine's performance.

How to Choose Wheel Alignment Machine Software

Choosing the right software for a wheel alignment machine is a crucial step in ensuring effective and precise alignment services. Here are some key factors to consider when selecting software:

- Compatibility: Ensure that the software is compatible with the hardware of the alignment machine. This includes checking the operating system requirements, communication protocols, and data transfer capabilities. Seamless integration between the software and the machine's sensors and cameras is essential for accurate results.

- Accuracy and Precision: Alignment accuracy is critical for customer satisfaction and safety. Look for software that provides highly accurate measurements and real-time adjustments. Consider independent reviews and comparisons that assess the precision of different software options.

- User-Friendly Interface: A user-friendly interface is essential for efficiency and ease of use. Technicians should be able to navigate the software easily, access required functions quickly, and interpret results without difficulty. Intuitive design, clear data presentation, and customizable layouts contribute to a smoother workflow.

- Data Management and Reporting: Consider the software's data management and reporting capabilities. It should allow technicians to store, retrieve, and analyze alignment data easily. Detailed reports, including before-and-after measurements, adjustments made, and recommendations, can enhance communication with customers and support business operations.

- Technical Support and Updates: Reliable technical support is crucial when using alignment machine software. Choose a supplier that offers responsive technical support, including assistance with installation, troubleshooting, and machine calibration. Additionally, inquire about regular software updates and improvements to ensure continued performance and access to new features.

- Training and Documentation: Check if the software supplier provides training programs and comprehensive documentation. Training sessions can help technicians maximize the software's potential and learn about advanced features. Detailed manuals, tutorials, and online resources contribute to a smoother learning curve and ensure the software's optimal use.

- Integration with Other Shop Systems: Consider the software's ability to integrate with other systems in the workshop, such as management, inventory, and diagnostic tools. Seamless integration streamlines operations, data sharing, and overall efficiency.

- Scalability and Future-Proofing: Choose software that can grow with the business. Consider alignment machine software for new features and capabilities to adapt to industry changes and technological advancements. Future-proofing ensures that the software remains relevant and effective for many years.

By considering these factors, businesses can choose alignment machine software that meets their needs, improves alignment accuracy, and enhances customer satisfaction. The right software will optimize alignment services and contribute to the success of the workshop.

How to DIY and Replace Wheel Alignment Machine Software

Here is a step-by-step guide on how to install or replace the software for a wheel alignment machine:

Before the procedure, ensure the following:

- The computer or laptop used for the wheel alignment machine meets the system requirements for the new software.

- Backup any important data from the old software, if applicable.

- Have a stable internet connection for downloading the software, if necessary.

Installation Steps:

- 1. Turn on the computer or laptop and connect it to the wheel alignment machine using the provided USB or Bluetooth connection.

- 2. Go to the official website of the wheel alignment machine software provider or the authorized dealer.

- 3. Navigate to the "Downloads" or "Support" section of the website.

- 4. Look for the latest version of the software for the wheel alignment machine and click on the download link.

- 5. Once the download is complete, locate the downloaded file and double-click on it to initiate the installation.

- 6. Follow the on-screen instructions to install the software.

- 7. The computer will prompt users to agree to the license agreement and select the installation location.

- 8. Select the alignment settings, such as toe, camber, caster, thrust angle, and others.

- 9. After the installation is complete, restart the computer or laptop.

- 10. Open the newly installed software and follow any initial setup instructions or calibrations required.

Update Steps:

- 1. Open the software for the wheel alignment machine on the computer or laptop.

- 2. Navigate to the "Settings" or "Help" section of the software.

- 3. Look for an option like "Check for Updates" or "Update Software."

- 4. The computer will prompt users to search for available updates and download them.

- 5. If an update is available, follow the on-screen instructions to install it.

- 6. Ensure the alignment data and settings are compatible with the updated software.

- 7. Restart the computer or laptop after the update is complete.

Q and A

Q1: What is the purpose of a wheel alignment check?

A1: The alignment of the wheels are checked to guarantee that they are appropriately adjusted. This is important to improve the presentation and security of the vehicle. Proper alignment of the wheels helps to maintain a straight direction of the vehicle and prevents untimely disintegration of the tires and other suspension parts.

Q2: How frequently should a wheel alignment be done?

A2: It's good to have a wheel alignment check every 10,000 to 15,000 miles or each time the tires are replaced. Besides, a check is recommended after a significant mishap, hitting a deep hole, or when there are signs of poor alignment, like uneven tire wear.

Q3: What are the signs of improper wheel alignment?

A3: Indications of incorrect wheel alignment include the vehicle pulling to one side, uneven tire wear, and the tires squealing on turning. Additionally, there may be a loose steering wheel, vibrations at high speeds, and visible changes in the position of the vehicle.

Q4: Can individuals perform a wheel alignment at home?

A4: Although it is possible to perform a basic wheel alignment at home using simple tools and measures, a precise alignment typically requires specialized equipment. If precise alignment cannot be guaranteed, it is advisable to go to a professional workshop.