1 Button Maker

About 1 button maker

Where to Find 1 Button Maker Suppliers?

China remains the central hub for button maker manufacturing, with key production clusters in Guangdong and Zhejiang provinces. These regions host vertically integrated supply chains that support both manual and pneumatic button-making machinery. Foshan (Guangdong) specializes in compact, single-station manual presses suited for small-scale apparel and accessory producers, while Hangzhou (Zhejiang) focuses on industrial-grade pneumatic systems capable of high-volume fastener attachment.

The concentration of component suppliers—ranging from die-cast molds to hydraulic units—within 50km radii enables rapid prototyping and reduced assembly lead times. This ecosystem supports flexible production runs, with standard models typically available within 15–25 days. Buyers benefit from localized steel and aluminum sourcing, which reduces material costs by 18–25% compared to non-Asian manufacturers. The region’s logistics infrastructure further enhances export efficiency, particularly for LCL and FCL shipments via Shenzhen and Ningbo ports.

How to Choose 1 Button Maker Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Machine Type Verification

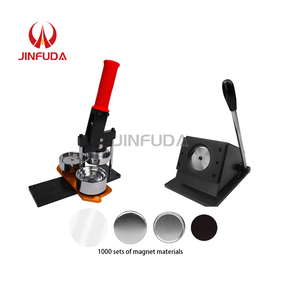

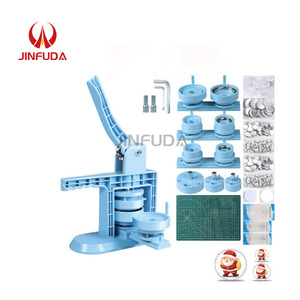

Confirm whether the supplier offers manual, pedal-driven, or pneumatic models based on production volume needs. Manual units (priced $18–$150/set) are suitable for startups and craft businesses, while pneumatic systems ($120–$1,600/set) serve medium to large garment factories requiring consistent pressing force. Validate compatibility with button sizes (commonly 1", 25mm, or 37mm) and materials such as metal, plastic, or resin.

Production Capacity and Customization Capability

Assess suppliers’ ability to accommodate customization requests:

- In-house tooling design for die heads and mold adjustments

- Material processing options: carbon steel, aluminum alloy, or stainless steel frames

- Branding services including logo engraving, color coating, and packaging design

- Minimum Order Quantity (MOQ) flexibility—ranging from 1 set for retail buyers to 5+ sets for distributors

Cross-reference product listings with supplier claims on response time and on-time delivery rates to assess operational reliability.

Quality Assurance and Transaction Security

Prioritize suppliers demonstrating adherence to quality management practices. While formal ISO certification is not universally listed, verified performance metrics such as 100% on-time delivery and sub-3-hour response times indicate strong internal controls. Utilize secure payment mechanisms where available, and request functional samples before bulk ordering. Test machines for press consistency, structural durability, and ease of die replacement under real-use conditions.

What Are the Best 1 Button Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (Lowest) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Foshan Zeming Hardware Technology Co., Ltd. | Foshan, CN | Buttons, Belt Buckles, Garment Eyelets | US $20,000+ | 100% | ≤3h | 28% | $18 | 1 set |

| Golden Gateway Trading Inc | N/A | GPS Trackers, Pet Devices | US $30,000+ | 89% | ≤3h | - | $54.60 | 1 piece |

| Hangzhou Anysew Garment Equipment Co., Ltd. | Hangzhou, CN | Pneumatic Snap Button Machines | US $70,000+ | 100% | ≤7h | 22% | $120 | 5 sets |

| Zhengzhou Hento Machinery Co., Ltd. | Zhengzhou, CN | Button Press & Attach Machines | US $360,000+ | 100% | ≤1h | 20% | $1,394 | 1 set |

| Foshan Yajiarui Machinery Co., Ltd. | Foshan, CN | Fridge Magnet & Packaging Machines | US $130,000+ | 100% | ≤1h | <15% | $39 | 1 set |

Performance Analysis

Foshan-based suppliers lead in responsiveness and low MOQ availability, making them ideal for SMEs and niche market entrants. Foshan Zeming offers entry-level manual models at competitive prices ($18/set), backed by a 28% reorder rate and perfect on-time delivery. Hangzhou Anysew specializes in industrial pneumatic solutions, though higher MOQs (5–10 sets) reflect its focus on commercial clients. Zhengzhou Hento commands the highest price tier, aligning with heavy-duty construction and automated integration capabilities. Golden Gateway, despite lower specialization in garment machinery, provides mid-range ergonomic designs with scalable order terms. Foshan Yajiarui demonstrates versatility beyond button makers into promotional product equipment, suggesting broader customization potential.

FAQs

How to verify 1 button maker supplier reliability?

Evaluate suppliers using verifiable metrics: on-time delivery rate (target ≥95%), average response time (ideal ≤3 hours), and reorder rate as an indicator of customer satisfaction. Request product specifications, operational videos, and, if possible, third-party inspection reports. Confirm post-purchase support availability for mechanical troubleshooting or spare part supply.

What is the typical sampling timeline for button makers?

Standard sample production takes 7–15 days depending on machine complexity. Manual models are typically shipped faster than customized pneumatic versions. Add 5–10 days for international air freight. Some suppliers offer digital operation demos in lieu of physical samples for initial assessment.

Can suppliers ship 1 button makers worldwide?

Yes, most suppliers support global shipping via express courier, air freight, or sea container. Confirm Incoterms (FOB, CIF, DDP) during negotiation. Sea freight is cost-effective for multiple-unit orders, while air transport suits urgent single-set deliveries. Ensure compliance with import regulations regarding electrical components if applicable.

Do manufacturers provide free samples?

Free samples are uncommon for machinery due to production and shipping costs. However, some suppliers deduct the sample fee from subsequent bulk orders. Expect to pay full price or a partial fee (50–80%) for functional units used in testing.

How to initiate customization requests?

Submit detailed requirements including desired press type (manual, foot-operated, pneumatic), frame material preference, force capacity (in kN), compatible button diameter range, and branding elements. Suppliers with customization tags can typically deliver modified prototypes within 2–3 weeks and provide CAD drawings upon request.