1 1 2 Button Maker

1/21

1/21

1/13

1/13

1/12

1/12

1/13

1/13

About 1 1 2 button maker

Where to Find 1 1/2 Inch Button Maker Suppliers?

China remains the central hub for button maker manufacturing, with key production clusters in Guangdong and Hebei provinces enabling competitive pricing and scalable output. Dongguan and Cangzhou serve as core industrial zones, hosting vertically integrated facilities that manage everything from die-casting molds to final assembly. These regions benefit from concentrated supply chains for metal stamping, plastic injection, and manual press components—reducing material lead times by up to 40% compared to offshore alternatives.

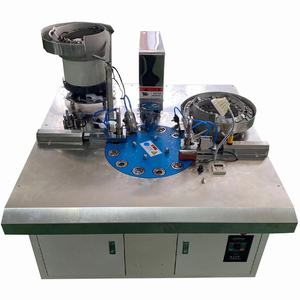

Suppliers in these clusters typically operate semi-automated and fully automatic production lines capable of producing 500–5,000 units monthly per line, depending on model complexity. Standard models support 25mm (1 inch) and 32mm (1 1/4 inch) diameters, while multi-size machines accommodate 1 1/2 inch (38mm) formats. The integration of local component vendors within a 30km radius ensures rapid replacement part availability and minimizes downtime during mass production runs.

How to Choose 1 1/2 Inch Button Maker Suppliers?

Procurement decisions should be guided by three core evaluation criteria:

Technical Capability Verification

Confirm machine compatibility with 1 1/2 inch (38mm) button components, including dies, base plates, and punch mechanisms. Request technical drawings or 3D models to validate dimensional accuracy. For industrial buyers, prioritize suppliers offering electric, pneumatic, or semi-automatic systems with throughput exceeding 600 pieces/hour. Manual desktop models are suitable for small-scale craft operations but lack scalability.

Production Capacity & Quality Assurance

Evaluate supplier infrastructure based on:

- Minimum facility size of 1,000m² indicating serious manufacturing intent

- In-house tooling and mold-making capabilities for custom die development

- On-time delivery rate above 95% as an indicator of operational reliability

Cross-reference order fulfillment history with response time metrics—suppliers responding within ≤4 hours demonstrate higher engagement and service readiness.

Transaction Security and Compliance

Insist on documented quality control processes, including pre-shipment inspections and functional testing of assembled units. While formal ISO 9001 certification is not universally present among smaller exporters, evidence of consistent online transaction volume (e.g., US $20,000+ annual revenue) correlates with reliable performance. Use secure payment methods such as escrow services to mitigate risk, especially when placing first-time orders.

What Are the Best 1 1/2 Inch Button Maker Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Dongguan Yibecs Machinery & Equipment Co., Ltd. | Guangdong, CN | 5+ | 50+ | 3,000+m² | 98% | ≤5h | N/A | 35% |

| HAO HANN ENTERPRISE CO., LTD. | Taiwan, CN | 10+ | 30+ | 2,500+m² | 100% | ≤7h | N/A | 33% |

| Cangzhou Longway Imp & Exp Co., Ltd. | Hebei, CN | 8+ | 40+ | 1,800+m² | 100% | ≤4h | N/A | <15% |

| Golden Gateway Trading Inc | Fujian, CN | 3+ | 10+ | 800+m² | 88% | ≤3h | N/A | - |

| Guangzhou Yuanin Technology Co., Ltd. | Guangdong, CN | 4+ | 35+ | 2,200+m² | - | ≤7h | N/A | <15% |

Performance Analysis

Dongguan Yibecs stands out with a 98% on-time delivery rate and specialization in apparel machinery, suggesting strong process discipline. HAO HANN ENTERPRISE demonstrates exceptional reliability with a perfect 100% delivery record and high reorder rate, supported by extensive experience in button-making equipment. Cangzhou Longway offers fast responsiveness (≤4h) and full compliance tracking, making it a viable option for urgent procurement cycles. Golden Gateway, while responsive, shows lower delivery consistency (88%), which may pose risks for time-sensitive contracts. Guangzhou Yuanin provides access to pneumatic and all-in-one automated systems but lacks verified delivery data, warranting additional due diligence.

FAQs

What is the typical MOQ for 1 1/2 inch button makers?

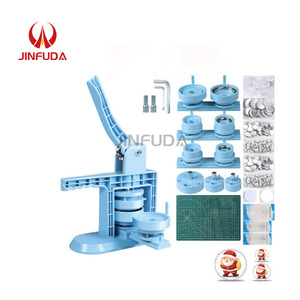

Minimum Order Quantities vary by supplier and model type. Manual desktop units often have MOQs as low as 1 piece, ideal for startups or testing. Industrial-grade machines are typically sold in sets or pairs with MOQs starting at 1 unit. Bulk configurations may require minimum purchases of 5–10 units for customized setups.

What are common lead times for shipment?

Standard models are generally available within 15–25 days after order confirmation. Customized or automated systems may require 30–45 days for production and testing. Air freight reduces delivery time to 5–10 days internationally, while sea shipping takes 20–35 days depending on destination port congestion.

Do suppliers offer customization options?

Yes, many manufacturers support OEM branding, voltage adjustments (110V/220V), and multi-diameter compatibility. Advanced models can be modified for left-hand operation or integrated into conveyor-based workflows. Confirm customization feasibility during initial inquiry and request prototype images before production begins.

Are samples available before bulk ordering?

Sample policies differ across suppliers. Some offer single-unit trials at full price, while others include sample units within larger orders. Expect to cover shipping costs and potential import duties. Testing a sample is recommended to assess build quality, ease of use, and alignment precision before scaling procurement.

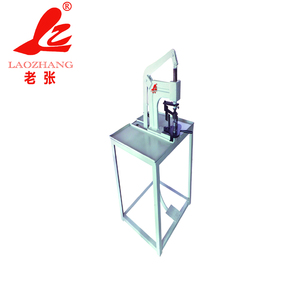

What materials are used in construction?

Entry-level models use reinforced ABS plastic and zinc alloy dies, suitable for low-volume use. Mid-range and industrial machines feature cast iron frames, hardened steel punches, and aluminum alloy pressing plates for durability under continuous operation. Pneumatic systems often include stainless steel air cylinders and pressure regulators rated for 6–8 bar operating ranges.