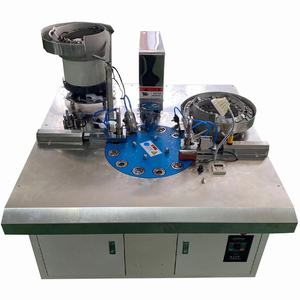

Button Maker Machine 2 1 4

CN

CN

About button maker machine 2 1 4

Where to Find Button Maker Machine 2 1 4 Suppliers?

China remains the dominant manufacturing hub for button maker machines, particularly models combining 2-in-1 and 4-in-1 functionality. Key industrial clusters are located in Guangdong, Zhejiang, and Henan provinces, each offering specialized advantages in automation, customization, and cost efficiency. Shenzhen and Qingdao serve as centers for high-precision automatic assembly systems, while Ningbo and Hangzhou focus on compact, multi-functional units suitable for small to mid-volume production environments.

These regional ecosystems support vertically integrated supply chains—from CNC machining and mold fabrication to final assembly—enabling rapid prototyping and scalable production. Buyers benefit from localized component sourcing, which reduces lead times by 20–30% compared to offshore alternatives. Average delivery windows range from 15–30 days for standard configurations, with select suppliers capable of fulfilling orders within 10 days due to pre-stocked modular components. The concentration of technical expertise and logistics infrastructure in these regions also supports competitive pricing, with unit costs typically 25–40% lower than equivalent Western-built machinery.

How to Choose Button Maker Machine 2 1 4 Suppliers?

Selecting a reliable supplier requires systematic evaluation across three core dimensions:

Technical Capability Verification

Confirm that the supplier offers machines compatible with required button diameters (e.g., 25mm, 38mm, 50mm) and materials (metal, plastic, fabric-covered). For automated lines, assess integration capabilities such as pneumatic pressing systems, adjustable stroke speed, and die-change mechanisms. Machines labeled "2-in-1" typically combine cap and base assembly, while "4-in-1" systems integrate feeding, positioning, pressing, and ejection processes. Request operational videos or facility walkthroughs to verify automation claims.

Production and Quality Assurance Standards

Prioritize suppliers with documented quality management systems. While ISO 9001 certification is not universally listed, consistent on-time delivery rates (≥97%) and low defect reports indicate process discipline. Evaluate build specifications including:

- Press force capacity (ranging from 1–5 tons for different button types)

- Tolerance precision (±0.1mm for die alignment)

- Durability testing data (cycles per machine life exceeding 100,000 operations)

- In-house tooling design and repair support

Cross-reference product listings with actual output capacity—some suppliers list both industrial-grade systems and DIY-level manual presses under the same keyword set.

Procurement and Transaction Safeguards

Assess supplier responsiveness (target ≤3 hours), reorder rate (indicative of customer satisfaction), and minimum order quantity (MOQ). Most industrial machines require MOQs of 1 set, though some offer sample units at slightly higher per-unit prices. Use secure payment terms such as escrow services or letter of credit for initial transactions. For customized tooling, confirm material compatibility (e.g., brass, stainless steel, or plastic blanks) and lead time for die modifications (typically 7–14 days).

What Are the Best Button Maker Machine 2 1 4 Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Online Revenue Tier |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Jiazhao High Tech Co., Ltd. | Automatic button making, heat press, sealing machines | $1,428 – $6,520 | 1 set | 100% | ≤3h | - | Limited | $7,000+ |

| Ningbo Yfd Machinery Manufacturing Co., Ltd. | DIY button makers, laminators, hole punches | $20 – $140 | 1 piece | 100% | ≤2h | 28% | No | $10,000+ |

| Qingdao QC Machinery Co.,LTD | Automatic snap button, eyelet pressing machines | $790 – $2,890 | 1 set/piece | 100% | ≤3h | <15% | Yes | $100,000+ |

| Zhengzhou Pasen Machinery Co., Ltd. | Plastic button covering, wrapping, hole punching | $750 – $3,680 | 1 set | 100% | ≤4h | 16% | Yes | $260,000+ |

| Hangzhou Qike Technology Co., Ltd. | Automatic button laminating, sewing, cutting | $390 – $1,980 | 1 set | 100% | ≤2h | 18% | Limited | $420,000+ |

Performance Analysis

Shenzhen Jiazhao and Hangzhou Qike offer mid-range automated solutions with strong delivery reliability and competitive pricing for entry-level industrial buyers. Ningbo Yfd stands out for low-cost, manual-to-semi-automatic units ideal for craft or promotional product businesses, supported by a high reorder rate of 28%. Qingdao QC and Zhengzhou Pasen provide customization options for material size, pressing force, and tooling design—critical for manufacturers producing non-standard fasteners. Despite lower reorder rates, both maintain high online transaction volumes, indicating broad market reach. Hangzhou Qike leads in affordability for basic automation, with models starting below $400, while Shenzhen Jiazhao caters to larger-scale operations with heavy-duty 4-in-1 systems priced above $5,000.

FAQs

How to verify button maker machine supplier reliability?

Check consistency in technical specifications across product listings. Request references or third-party inspection reports if available. Analyze response patterns: suppliers with sub-4-hour average replies and 100% on-time delivery have demonstrated operational stability. For custom tooling, verify experience with your specific button type (e.g., denim snaps, plastic badges).

What is the typical lead time for button maker machines?

Standard models ship within 10–20 days after order confirmation. Customized machines with modified dies or automation features require 20–35 days. Air freight adds 5–7 days for international delivery; sea freight ranges from 25–45 days depending on destination port.

Can suppliers accommodate OEM branding or private labeling?

Yes, select suppliers like Zhengzhou Pasen and Qingdao QC offer logo printing, color customization, and packaging adjustments. Minimum volume requirements typically start at 5 sets for branded units. Confirm label design approval process and additional costs during negotiation.

Do button maker machines support multiple button sizes?

Most 2-in-1 and 4-in-1 machines support interchangeable dies for diameters ranging from 18mm to 50mm. Confirm die changeover time and availability of spare tooling kits. Some models are optimized for specific applications (e.g., jeans buttons vs. souvenir badges).

Are spare parts and technical support included?

Basic warranties (6–12 months) cover critical components like motors and hydraulic units. Reputable suppliers provide operation manuals, video tutorials, and remote troubleshooting. For long-term maintenance, confirm availability of wear-prone parts such as punch pins, dies, and air cylinders.