1.5 Button Maker

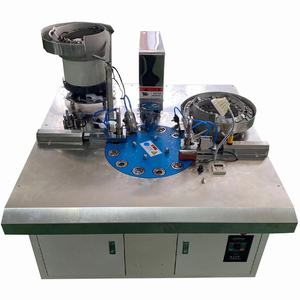

About 1.5 button maker

Where to Find 1.5 Button Maker Suppliers?

China remains the central hub for industrial button-making machinery production, with key manufacturing clusters in Hebei, Henan, and Shandong provinces. These regions host vertically integrated supply chains specializing in textile automation equipment, metal fastening systems, and garment accessory machinery. Anping County in Hebei Province is particularly notable for its concentration of wire mesh and mechanical fabrication enterprises, enabling synergies in precision machining and component sourcing. Henan’s Zhengzhou and Longnan areas feature specialized workshops focused on sewing automation and electromechanical assembly, supporting cost-efficient production of button attaching and cover button machines.

The regional ecosystems offer scalable manufacturing capacity, with many suppliers operating facilities exceeding 2,000m² and maintaining in-house capabilities in CNC machining, welding, and final assembly. This integration supports lead times averaging 20–35 days for standard configurations, with localized access to motors, dies, and control systems reducing material procurement cycles. Buyers benefit from competitive pricing structures—driven by economies of scale—and flexibility in both batch production and limited customization, particularly for automated or semi-automated 1.5-inch button making units.

How to Choose 1.5 Button Maker Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers possess proven experience in producing button-making machinery for 1.5-inch (38mm) applications. Key indicators include product listings specifying die compatibility, feed mechanisms, and output capacity. For automated models, assess integration of servo drives, pneumatic pressing systems, and programmable logic controllers (PLCs). Machines designed for fabric-covered buttons should demonstrate adjustable pressure settings and multi-material handling (fabric, leather, plastic).

Production and Quality Benchmarks

Evaluate supplier infrastructure using these criteria:

- Minimum factory area of 1,000m² to support stable production

- In-house tooling and mold-making capabilities for custom dies

- Documented quality control processes, including pre-shipment testing protocols

Prioritize suppliers with verifiable on-time delivery rates above 97% and response times under 4 hours, which correlate with operational reliability.

Transaction Security and Compliance

Insist on third-party payment protection mechanisms where available. Review transaction history for consistent fulfillment patterns and minimal disputes. While formal certifications such as ISO 9001 or CE are not universally listed, their absence should prompt deeper due diligence through facility videos, sample inspections, and direct technical inquiries. Request performance data on machine cycle life (target: 100,000+ operations) and mean time between failures (MTBF).

What Are the Best 1.5 Button Maker Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Anping Boming Wiremesh Manchinery Manufacturing Co., Ltd. | Wire Mesh Making Machines, Fencing Equipment | $3,500–3,750 | 1 set | 100% | ≤2h | $60,000+ | <15% |

| Henan Penghui Machinery And Equipment Co., Ltd. | Fabric Cover Button Machines, Snap Presses | $2,600–11,950 | 1 set | 98% | ≤3h | $340,000+ | <15% |

| Longnan City Brotherholding Protective Equipment Co., Ltd. | Sewing Machines, Button Attaching Equipment | $750–2,885 | 1 piece/set | 100% | ≤4h | $5,000+ | 100% |

| Yantai Panda Equipment Co., Ltd. | Mining Drill Bit Sharpeners, Grinders | $540–580 | 1 set | 100% | ≤1h | $80,000+ | <15% |

| Mejoroom Inc | Blenders, Juicers, Small Appliances | $4.18–7.69 | 5–504 pieces | - | ≤1h | - | - |

Performance Analysis

Suppliers like Anping Boming and Longnan City Brotherholding demonstrate high on-time delivery compliance (100%), indicating strong production planning and execution. Henan Penghui offers the widest range of dedicated button-making solutions, including fully automatic fabric-covered button machines priced at $7,560 per set, with significant online transaction volume suggesting market validation. Longnan stands out for customer retention, reporting a 100% reorder rate despite moderate response speed, potentially reflecting niche expertise in used or refurbished industrial sewing systems.

Yantai Panda focuses on tool maintenance equipment rather than end-use button makers, positioning it as a peripheral player in this category. Mejoroom Inc appears misaligned with the intended application, listing blenders under the keyword "button maker, 1.5"—likely due to algorithmic indexing errors. Procurement professionals should filter such entries during vendor shortlisting.

FAQs

How to verify 1.5 button maker supplier reliability?

Cross-check product specifications against physical capabilities via video audits or third-party inspection services. Request test reports on pressing force (typically 5–8 tons for 1.5-inch dies), cycle speed (600–1,200 units/hour), and electrical safety compliance. Analyze historical shipping records and buyer feedback focusing on after-sales support and spare parts availability.

What is the typical MOQ and lead time?

Standard minimum order quantities are 1 set for complete machines, though some suppliers accept trial orders. Lead times range from 15 to 30 days post-deposit, depending on automation level and customization. Simple mechanical presses ship faster than PLC-controlled or fully automatic models.

Can suppliers customize button makers for specific materials?

Yes, many manufacturers offer adjustments for fabric thickness, metal backing type, and button diameter within the 1.5-inch format. Custom tooling may require additional setup fees and extended delivery schedules. Confirm whether CAD drawings or prototype validation are provided prior to production.

Do suppliers provide technical support and training?

Support varies by vendor. Leading suppliers typically include basic operation manuals and troubleshooting guides. Advanced training—such as machine calibration or die replacement—is often available upon request, sometimes at an additional cost. Remote diagnostics via video call are increasingly common among responsive suppliers.

What are the packaging and shipping options?

Machines are generally crated in wooden enclosures suitable for sea freight. Suppliers may offer FOB, CIF, or DDP terms. Confirm whether voltage (220V/380V) and plug types match destination country standards. Air freight is viable for single units but significantly increases logistics costs.