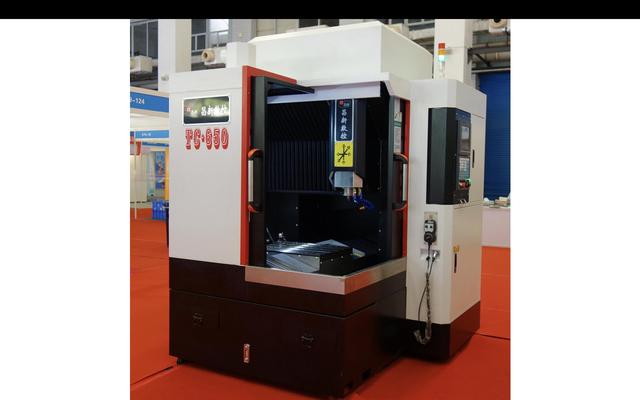

3 Axis Cnc Lathe Machine Manufacturers

CN

CN

About 3 axis cnc lathe machine manufacturers

Where to Find 3 Axis CNC Lathe Machine Manufacturers?

China remains the dominant hub for 3 axis CNC lathe machine manufacturing, with key industrial clusters concentrated in Shandong and Guangdong provinces. These regions host vertically integrated production ecosystems that combine casting, precision machining, and final assembly under one supply chain, enabling cost efficiencies of 20–35% compared to Western or Southeast Asian producers. Shandong’s Jining and Jinan zones specialize in mid-to-high-end CNC turning equipment, supported by proximity to steel suppliers and rail logistics networks that reduce material lead times by up to 40%.

The region's mature supplier base offers scalable production capacity, with manufacturers typically operating facilities exceeding 5,000m² and maintaining in-house CNC component fabrication lines. This integration supports faster prototyping (7–14 days) and shorter delivery cycles—standard orders are fulfilled within 30–60 days. Buyers benefit from flexible MOQs starting at 1 set, widespread adoption of Fanuc, Siemens, and SYNTEC control systems, and growing capabilities in custom automation integration.

How to Choose 3 Axis CNC Lathe Machine Manufacturers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Systems

Verify adherence to ISO 9001 quality management standards as a baseline. For export markets, confirm CE marking compliance to meet EU machinery directives. Request documentation on spindle accuracy testing (runout ≤0.005mm), linear guide rail calibration, and servo motor performance logs. Machines should comply with IEC 60204-1 safety standards for electrical systems.

Production Capability Assessment

Evaluate manufacturer infrastructure using these benchmarks:

- Minimum factory area of 3,000m² for stable batch production

- In-house CNC machining centers for critical sub-assemblies (e.g., headstocks, turrets)

- Dedicated R&D teams focused on motion control optimization and error compensation algorithms

Cross-reference online revenue data and reorder rates: suppliers with reorder rates above 25% and response times under 3 hours demonstrate stronger customer satisfaction and service reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to ensure funds are released only after equipment verification. Prioritize suppliers with transparent transaction histories and documented after-sales support policies. Conduct pre-shipment inspections to validate machine geometry, surface finish consistency, and control system functionality against agreed specifications.

What Are the Leading 3 Axis CNC Lathe Machine Manufacturers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Taian Haishu Machinery Co., Ltd. | Shandong, CN | CNC Lathe (2015) | US $150,000+ | 100% | ≤3h | 27% | $8,000–25,000 |

| Shandong Hongyunlai Industrial Technology Co., Ltd. | Shandong, CN | CNC Lathe (142) | Not disclosed | 100% | ≤11h | - | $11,423–110,000 |

| Zhongshan Tengyue Cnc Technology Co., Ltd. | Guangdong, CN | CNC Lathe (303) | Not disclosed | 100% | ≤2h | - | $20,500–22,600 |

| Shandong Handemo Technology Co., Ltd. | Shandong, CN | CNC Lathe (116) | US $20,000+ | - | ≤9h | <15% | $8,350–14,153 |

| Shandong Yijin Cnc Machine Tool Co., Ltd. | Shandong, CN | Machining Centre (3273), CNC Lathe (651) | US $40,000+ | 100% | ≤1h | 50% | $8,500–22,000 |

Performance Analysis

Taian Haishu stands out for high-volume listing activity and strong reorder performance, indicating market acceptance of its product range. Zhongshan Tengyue and Shandong Yijin demonstrate superior responsiveness (≤2h and ≤1h respectively), which correlates with higher buyer engagement. Notably, Shandong Yijin reports a 50% reorder rate—the highest among peers—suggesting robust post-sale support and machine reliability. While some manufacturers offer entry-level models below $9,000, premium configurations with Fanuc or SYNTEC controls reach $22,000–$25,000, reflecting investment in rigidity, thermal stability, and precision components. Suppliers based in Shandong dominate geographic presence, accounting for four of the five listed companies, underscoring the province’s centrality in CNC lathe production.

FAQs

What is the typical MOQ for 3 axis CNC lathe machines?

Most manufacturers set a minimum order quantity of 1 set, facilitating procurement for small workshops and pilot projects. Bulk pricing applies incrementally beyond three units, with discounts negotiable based on long-term partnership potential.

How long does it take to deliver a 3 axis CNC lathe?

Standard delivery timelines range from 30 to 60 days after order confirmation, depending on customization level. Machines requiring specialized tooling, dual turrets, or enhanced coolant systems may extend lead times by 15–20 days.

Can I request customization on control systems or bed length?

Yes, leading manufacturers support tailored configurations including choice of Fanuc, Siemens, or SYNTEC controllers, extended swing diameters, and modified chuck sizes. Customization feasibility should be confirmed through engineering reviews and 3D layout approvals prior to production release.

Do suppliers provide installation and training support?

Many offer remote setup guidance via video. On-site commissioning and operator training are typically available at additional cost. Ensure service terms—including travel fees and duration—are specified in the contract before shipment.

Are there options for third-party inspection before shipment?

Yes, reputable manufacturers permit pre-shipment inspections by SGS, Bureau Veritas, or client-appointed engineers. Inspection scope may include dynamic runout tests, positioning accuracy checks (±0.01mm over 100mm), and safety interlock validation.