3 Axis Cnc Milling Machine Factory

CN

CN

About 3 axis cnc milling machine factory

Where to Find 3 Axis CNC Milling Machine Suppliers?

China remains the global epicenter for 3 axis CNC milling machine manufacturing, with key production hubs concentrated in Shandong and Jiangsu provinces. These regions host vertically integrated factories equipped with full-cycle production lines—from casting and machining to final assembly—enabling rapid turnaround and cost efficiency. Shandong, in particular, benefits from proximity to major steel suppliers and logistics ports, reducing raw material lead times by up to 20% compared to non-industrial cluster zones.

The industrial ecosystem supports both standard and customized machine builds, with many suppliers operating dedicated R&D units to support design adaptation. Factories typically maintain monthly output capacities ranging from 50 to over 200 units, depending on model complexity. Buyers benefit from localized supply chains that reduce production costs by 18–25% versus Western or Southeast Asian alternatives, while maintaining compliance-ready engineering frameworks for international markets.

How to Choose 3 Axis CNC Milling Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to ISO 9001 standards as a baseline for quality management. For export to regulated markets (EU, North America), confirm CE marking and functional safety documentation. Request test reports for critical components such as linear guide rails, ball screws, spindles, and control systems (e.g., Fanuc, Siemens, or Syntec compatibility). Machines should meet ISO 230-2 (positioning accuracy) and ISO 230-3 (geometric accuracy) benchmarks.

Production Capability Verification

Assess infrastructure maturity through objective indicators:

- Factory area exceeding 3,000m² to ensure scalable production capacity

- In-house machining centers and heat treatment capabilities to control component precision

- Dedicated quality inspection stations with laser interferometers or CMM equipment

Cross-reference claimed capabilities with verified performance metrics such as on-time delivery rates (>97%) and reorder frequency.

Customization & After-Sales Support

Confirm availability of customization options including worktable size, spindle power (5–15kW range), automation integration (ATC, rotary tables), and control system preferences. Evaluate after-sales readiness—suppliers should offer remote diagnostics, installation guidance, and spare parts availability. Video audits of production floors and testing procedures provide transparency before order placement.

What Are the Leading 3 Axis CNC Milling Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (USD) |

|---|---|---|---|---|---|---|---|

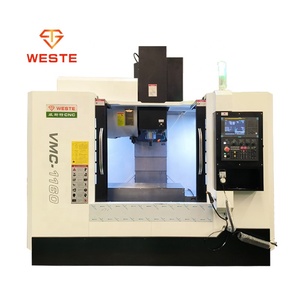

| Shandong Selection Machinery Co., Ltd. | Shandong, CN | Machining Centre (219), CNC Lathe (148) | 100.0% | ≤1h | - | - | $14,888–36,000 |

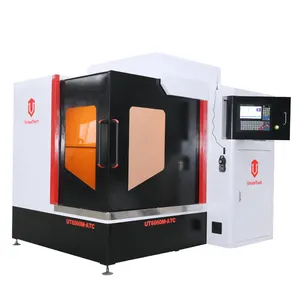

| Jinan Uniontech Machinery Co., Ltd. | Shandong, CN | CNC Milling Machines, Engraving Systems | 100.0% | ≤2h | <15% | US $940,000+ | $3,500–35,000 |

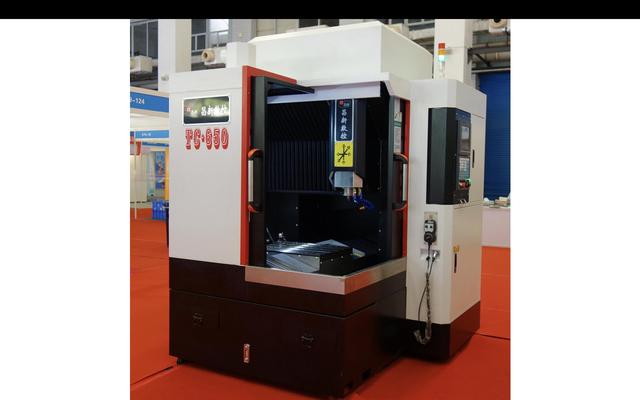

| Jinan Smart Technology Co., Ltd. | Shandong, CN | Mini CNC Mills, Drilling Centers | 100.0% | ≤2h | 50% | US $340,000+ | $2,400–14,000 |

| Jinan Chentuo Cnc Equipment Co., Ltd. | Shandong, CN | Desktop CNC, ATC Routers | 100.0% | ≤3h | 21% | US $300,000+ | $1,000–14,000 |

| Shanghai Sumore Industrial Co., Ltd. | Shanghai, CN | Mini & Hobby CNC Mills | 100.0% | ≤3h | 37% | US $70,000+ | $2,000–7,950 |

Performance Analysis

Shandong-based manufacturers dominate in scale and responsiveness, with Shandong Selection Machinery offering high-end models (up to $36,000) suitable for industrial applications requiring Taiwan-sourced components. Jinan Smart Technology stands out with a 50% reorder rate, indicating strong customer satisfaction in the mid-range segment. Shanghai Sumore and Jinan Chentuo focus on entry-level and desktop models, ideal for prototyping and small workshops. All listed suppliers maintain 100% on-time delivery, but response speed varies—prioritize those with sub-2-hour reply times for time-sensitive procurement cycles. Higher online revenue correlates with broader customization offerings and video-supported technical validation.

FAQs

What is the typical MOQ and lead time for 3 axis CNC milling machines?

Minimum Order Quantity is generally 1 set, accommodating sample and single-unit purchases. Standard lead time ranges from 15 to 30 days post-deposit, depending on customization level. Complex configurations with automatic tool changers or reinforced cast iron beds may extend to 45 days.

Can suppliers provide machine customization?

Yes, most suppliers offer configurable options including table dimensions, spindle RPM (6,000–24,000), control systems (SYNTEC, DSP, or Mach3), and structural materials (Meehanite cast iron or welded steel). Custom branding, voltage adaptation (380V/50Hz vs. 220V/60Hz), and safety guarding are commonly available.

How to verify factory claims remotely?

Request timestamped videos of active production lines, machining tests, and quality checks. Ask for photos of nameplates, electrical cabinets, and core components. Third-party inspection services (e.g., SGS, TÜV) can conduct pre-shipment audits for orders exceeding $20,000.

Are samples available before bulk purchase?

Full-machine samples are typically billable but creditable against future orders. Buyers should expect to cover 100% of unit cost and shipping initially. Some suppliers offer discounted demo units for evaluation, particularly for repeat clients.

What are common payment and logistics terms?

Standard terms include 30% advance payment via T/T, balance before shipment. Escrow arrangements are advised for first-time transactions. FOB Qingdao or FOB Shanghai is standard; CIF terms are available upon request. Sea freight is recommended for full-container loads, while LCL or air freight suits single units despite higher costs.