3 Types Of Alternator

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About 3 types of alternator

Where to Find 3 Types of Alternator Suppliers?

China remains the central hub for alternator manufacturing, with key production clusters in Guangdong, Fujian, and Jiangsu provinces. These regions host vertically integrated facilities specializing in automotive and industrial-grade alternators, including single-phase, three-phase, and brushless variants. Guangdong and Fujian are particularly dominant in export-oriented electrical component production, leveraging localized supply chains for copper windings, voltage regulators, and rotor assemblies, reducing material procurement cycles by up to 30%.

The industrial ecosystems in these zones support rapid prototyping and scalable batch production, enabling suppliers to fulfill both small-volume technical orders and large-scale OEM contracts. Proximity to Shenzhen and Xiamen ports ensures efficient global logistics, with standard lead times averaging 15–25 days post-confirmation. Buyers benefit from competitive pricing due to economies of scale, access to certified component vendors within 50km radii, and established quality control frameworks aligned with international export standards.

How to Choose 3 Types of Alternator Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Confirm alignment with core performance parameters: phase type (single/three-phase), output voltage (e.g., 220V/380V), frequency (50/60Hz), and power rating (kW/kVA). While formal ISO 9001 or CE certification is not explicitly stated in available data, prioritize suppliers who provide detailed test reports for insulation resistance, temperature rise, and load regulation. For industrial applications, verify compatibility with diesel or gas-powered generator sets.

Production and Customization Capability

Assess supplier capacity based on product range and customization indicators:

- Broad kW/kVA offerings (from 2kW to 200kW) indicate scalable design and winding expertise

- Availability of brushless, synchronous, and AC three-phase models reflects technical versatility

- Customization tags (e.g., color, branding, silent box integration, phase configuration) suggest engineering flexibility for OEM integration

Cross-reference listed product portfolios with response times and reorder rates as proxies for operational reliability and customer satisfaction.

Transaction Reliability & Risk Mitigation

Prioritize suppliers with documented performance metrics:

- On-time delivery rate ≥100% across multiple suppliers indicates consistent logistics execution

- Reorder rates above 50% (e.g., 66% for top-tier supplier) reflect strong post-sale satisfaction

- Response time ≤2 hours enables faster technical clarification and order processing

Implement third-party inspection protocols before shipment and utilize secure payment mechanisms to mitigate fulfillment risk, especially for high-value units exceeding $10,000/set.

What Are the Best 3 Types of Alternator Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility | Key Product Range |

|---|---|---|---|---|---|---|---|

| Jiangsu Haut Mechanical Co., Ltd. | Alternators, Generators, Diesel Sets | US $510,000+ | 100% | ≤2h | 50% | 1 set | 30kW–200kW, All-Copper Windings |

| Fuan Westin Jet Electric Machinery Co., Ltd. | Diesel/Hydro Generators, Alternators | US $610,000+ | 100% | ≤5h | 66% | 10 sets | 10kW–100kVA, Brushless Design |

| Fuan Shenzhou Electrical Co., Ltd. | Generator Heads, Diesel Generators | US $20,000+ | 100% | ≤4h | 44% | 1 set | 25kVA–100kVA, Synchronous AC |

| Fujian Zfly Power Generation Co., Ltd. | AC Alternators, Generator Sets | US $2,000+ | 100% | ≤18h | 50% | 1 piece | 2kW–100kW, Three-Phase Brushless |

| Guangzhou Hongyang Auto Parts Co., Ltd. | Auto Alternators, Engine Components | US $90,000+ | 100% | ≤1h | 36% | Not specified | Automotive Grade (Multiple Models) |

Performance Analysis

Jiangsu Haut and Fuan Westin lead in revenue volume and technical breadth, offering high-power alternators suitable for industrial and energy applications. Fuan Westin stands out with a 66% reorder rate—indicating strong customer retention—despite requiring minimum orders of 10 sets. Jiangsu Haut provides one-set flexibility with premium all-copper models up to 200kW, ideal for customized power solutions. Fujian Zfly and Fuan Shenzhou cater to mid-range demands with competitive pricing and single-unit availability, beneficial for testing and low-volume integration. Guangzhou Hongyang focuses on automotive alternators with fast response times (≤1h), making it a responsive option for vehicle part sourcing. All top suppliers maintain 100% on-time delivery, underscoring reliable logistics execution across the segment.

FAQs

What are the 3 main types of alternators available from these suppliers?

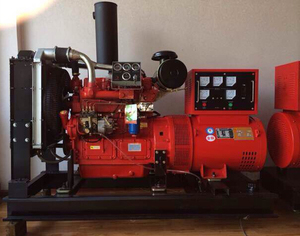

The three primary types include single-phase alternators (used in light-duty applications), three-phase alternators (standard for industrial generators), and brushless alternators (preferred for durability and reduced maintenance in continuous operation environments).

What is the typical MOQ and lead time for alternator orders?

Minimum Order Quantities range from 1 set (common for high-power units) to 10 sets (for standardized models). Lead times typically fall between 15 and 25 days after deposit confirmation, depending on customization level and factory workload.

Can suppliers customize alternators for specific applications?

Yes, several suppliers offer customization for voltage, frequency, cooling method, mounting configuration, branding, and enclosure type (e.g., silent boxes). Engineering modifications such as phase conversion, material upgrades (e.g., all-copper windings), and integration with engine systems are feasible upon request.

What payment and assurance terms should buyers consider?

Use milestone-based payments with deposit (30%), pre-shipment inspection (60%), and final balance upon confirmation. Leverage transaction protection programs where available, and require product-specific test reports prior to dispatch. Third-party inspections are recommended for orders exceeding five units.

How do I evaluate alternator quality without on-site audits?

Analyze product specifications for copper vs. aluminum windings, IP protection ratings, insulation class (e.g., Class H), and thermal protection features. Request no-load and full-load test videos, and verify consistency in voltage regulation and waveform stability. High reorder rates and responsive communication serve as indirect indicators of product reliability.