3d Printed Composite Tooling

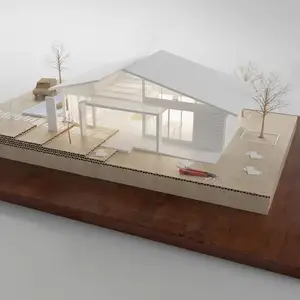

About 3d printed composite tooling

Where to Find 3D Printed Composite Tooling Suppliers?

China leads global production of 3D printed composite tooling, with concentrated manufacturing hubs in Guangdong and Zhejiang provinces. These regions host vertically integrated facilities combining additive manufacturing, CNC machining, and mold design under one roof. Guangzhou and Dongguan serve as primary centers for rapid prototyping and low-volume production, leveraging localized access to industrial-grade polymers, resins, and metal composites. This integration reduces material lead times by 20–35% compared to decentralized supply chains.

Suppliers in these clusters operate advanced fabrication lines utilizing SLA, SLS, FDM, and MJF technologies, enabling high-precision tooling for aerospace, automotive, and medical applications. The ecosystem supports both small-batch customization and scalable production runs, with average monthly output ranging from 1,000 to 10,000 units per facility. Proximity to ports like Shenzhen and Hong Kong ensures efficient export logistics, with typical air freight delivery timelines of 7–10 days to North America and Europe.

How to Choose 3D Printed Composite Tooling Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

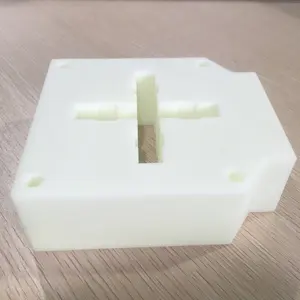

Confirm the supplier's proficiency in handling engineering-grade materials such as PA (nylon), ABS, PC, PEEK, and photopolymer resins. Evaluate their use of industrial 3D printing systems (e.g., Stratasys, EOS, Formlabs) and post-processing capabilities including heat treatment, surface finishing, and assembly. For functional tooling, dimensional accuracy must meet ±0.1mm tolerance standards. Request sample parts or STL file validation reports to verify print resolution and structural integrity.

Quality Management Systems

While formal ISO 9001 certification is not universally listed, prioritize suppliers demonstrating consistent quality metrics. Key indicators include on-time delivery rates exceeding 95%, response times under 5 hours, and documented rework procedures. Reorder rates above 80% suggest strong customer satisfaction and process reliability. Inquire about internal inspection protocols, including first-article testing and batch traceability.

Production Flexibility & Scalability

Assess minimum order quantity (MOQ) policies—ranging from single-unit prototypes to bulk orders starting at 100 pieces. Suppliers offering free samples or low-cost trial runs provide reduced risk for initial engagement. Verify scalability through facility size, workforce capacity, and concurrent project load. Cross-reference online revenue data and product diversity to gauge operational maturity.

Transaction Security and Communication Efficiency

Prioritize partners with sub-10-hour response times and transparent communication channels. High reorder rates combined with 100% on-time delivery indicate operational discipline. Utilize secure payment methods and request digital proof-of-production documentation before shipment. Confirm packaging standards for fragile printed components to prevent transit damage.

What Are the Best 3D Printed Composite Tooling Suppliers?

| Company Name | Main Products | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Machining Services, Moulds, Fabrication | 1 unit | $0.35–1.55 | 100% | ≤5h | 80% | US $30,000+ |

| Guangzhou Mr.mould Electrical Appliance Co., Ltd. | Plastic Products, Moulds, Machining | 1 unit/set | $1–200 | 100% | ≤4h | <15% | US $90,000+ |

| TONGSHENG TONGCHUANG INTELLIGENT EQUIPMENT COMPANY LIMITED | Machining, Sheet Metal, Springs | 100 pieces | $2.14–2.50 | 100% | ≤10h | - | US $90+ |

| Dongguan Dayi Hardware Products Co., Ltd. | Machining, Gaskets, Fasteners | 1 piece | $0.01–10 | 83% | ≤5h | 25% | US $2,000+ |

| Taizhou Changrong Technology Co., Limited | Machining, Moulds, Casting | 1 piece | $0.30–5 | 100% | ≤3h | 100% | US $10,000+ |

Performance Analysis

Guangzhou Gaojie and Taizhou Changrong stand out for balancing responsiveness, delivery reliability, and repeat business performance. Taizhou Changrong’s 100% reorder rate indicates exceptional service consistency, while its $0.30 minimum price point offers cost efficiency for entry-level prototyping. Guangzhou Mr.mould handles higher-value projects with a broad price ceiling up to $200, though its low reorder rate suggests potential gaps in long-term client retention despite high output volume.

TONGSHENG TONGCHUANG enforces a 100-piece MOQ, positioning it for mid-volume production rather than prototype development. Conversely, Dongguan Dayi offers ultra-low pricing down to $0.01 per piece but records an 83% on-time delivery rate, signaling possible logistical bottlenecks. Buyers requiring rapid turnaround should prioritize suppliers with response times under 5 hours and verified 100% delivery records.

FAQs

How to verify 3D printed composite tooling supplier reliability?

Evaluate on-time delivery history, reorder rate, and response time metrics. Request evidence of completed projects, including photos, test reports, or CAD/STL compatibility verification. For critical applications, conduct virtual factory audits to assess equipment condition and workflow organization.

What is the typical lead time for custom tooling?

Standard prototypes are delivered within 3–7 days after design approval. Complex assemblies or large batches may require 10–15 days. Add 5–10 days for international shipping via express carriers. Expedited services are available from select suppliers for urgent requests.

Can suppliers accommodate material-specific requirements?

Yes, most suppliers support common thermoplastics (PA, ABS, PC) and resin-based composites. Advanced materials like PEEK or carbon-fiber-reinforced filaments may require special quotation. Confirm material certifications and moisture resistance ratings for end-use environments.

Do manufacturers offer free samples?

Some suppliers provide free samples for qualified buyers, particularly when followed by volume commitments. Others charge nominal fees (e.g., $0.01–$5) that may be credited toward future orders. Sample availability depends on complexity and material cost.

How to initiate a customization request?

Submit detailed technical drawings, 3D models (STP, STL, IGES), and specifications including tolerances, surface finish, and intended application. Reputable suppliers respond within 24 hours with feasibility assessments, estimated pricing, and production timelines.