3d Printer Prototype Service

About 3d printer prototype service

Where to Find 3D Printer Prototype Service Suppliers?

China remains the global epicenter for 3D printing and rapid prototyping services, with concentrated supplier clusters in Shenzhen, Qingdao, and Xiamen offering scalable manufacturing ecosystems. These regions host vertically integrated facilities that combine additive manufacturing capabilities—such as FDM, SLA, SLS, and PolyJet—with secondary processing like CNC machining, surface finishing, and 3D scanning. Shenzhen leads in electronics-integrated prototypes and low-volume production, while Xiamen specializes in industrial-grade metal 3D printing using SLM and DMLS technologies.

The industrial advantage lies in localized supply chains for critical components, including laser systems, photosensitive resins, and high-performance polymers (e.g., ABS, PA12, TPEE), reducing material lead times by up to 40%. Suppliers in these hubs typically operate multi-technology production lines, enabling hybrid workflows from digital modeling to functional testing. Buyers benefit from average lead times of 5–12 days for prototype batches, with express turnaround options under 72 hours for urgent requests. Economies of scale support MOQs as low as one piece, making these clusters ideal for R&D teams, startups, and contract manufacturers requiring agile development cycles.

How to Choose 3D Printer Prototype Service Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

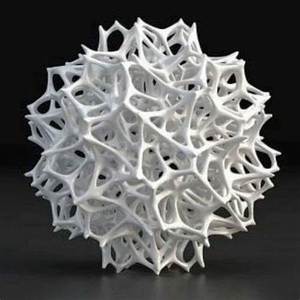

Technical Capability Verification

Confirm access to required printing technologies: FDM for cost-effective thermoplastic prototypes, SLA/DLP for high-resolution resin models, SLS for durable nylon-based parts, and metal SLM for end-use components. Suppliers should provide build volume specifications, layer resolution data (typically 25–100μm), and post-processing options such as sandblasting, electroplating, or Pantone-compliant painting. For engineering applications, validate material certifications (e.g., UL94 flame ratings, biocompatibility) and dimensional accuracy reports within ±0.1mm.

Production & Quality Infrastructure

Assess operational maturity through key indicators:

- Minimum of 10 industrial 3D printers per facility to ensure redundancy and capacity

- In-house design support for file optimization, topology simulation, and DfAM (Design for Additive Manufacturing)

- Integration of metrology tools (e.g., CMM, 3D scanners) for first-article inspection

Prioritize suppliers with documented quality management systems; ISO 9001 certification is a baseline indicator of process control. On-time delivery rates exceeding 97% correlate strongly with stable production planning.

Customization & Transaction Security

Ensure clear protocols for IP protection when submitting CAD files. Use secure channels for data transfer and require NDAs where necessary. Leverage platforms with built-in transaction safeguards, focusing on suppliers with proven dispute resolution records. Sample validation is critical—request physical test prints to evaluate surface finish, mechanical integrity, and color fidelity before scaling to batch production.

What Are the Best 3D Printer Prototype Service Suppliers?

| Company Name | Main Technologies | Monthly Output Capacity | On-Time Delivery | Avg. Response | Reorder Rate | Key Materials | Customization Support | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Soongon Technology Co., Ltd. | FDM, SLA, SLM, Metal 3D Printing | 1,387+ units/services | 100% | ≤2h | 37% | ABS, Resin, PA12, TPU, Titanium | Yes (design, scanning, coating) | US $330,000+ |

| Hangzhou Aoyi Trade Co., Ltd. | SLA, SLS, DLP, PolyJet | 5+ product lines | 97% | ≤2h | 53% | Resin, PEBA, Cobalt-Chromium, Brass | Extensive (electroplating, full-color, wax casting) | US $170,000+ |

| Xiamen Inone Technology Co., Ltd. | SLM, SLS, SLA, Industrial 3D Printers | 189+ printer models | 100% | ≤1h | 100% | Stainless Steel, Tool Steel, Aluminum | Limited (machine sales focus) | US $1,000+ |

| 24K Investment (Qingdao) Co., Ltd. | FDM, SLA, PolyJet, CNC Hybrid | 166+ machining services | 94% | ≤2h | 21% | ABS, Resin, PA12, Metal Alloys | Yes (hybrid fabrication) | US $10,000+ |

| Shanghai Auran Instrument & Equipment Co., Ltd. | FDM, SLA, Scanning Integration | 585+ printer listings | 100% | ≤2h | <15% | PLA, ABS, PETG, Engineering Polymers | Basic (printer resale + service) | US $50,000+ |

Performance Analysis

Shenzhen Soongon stands out for comprehensive service breadth and high reorder frequency, supported by robust customization and responsive communication. Hangzhou Aoyi demonstrates strong niche expertise in high-precision resin and metal prototyping, with advanced finishing options including chrome plating and full-color printing—ideal for consumer product mockups. Xiamen Inone excels in industrial metal printing but primarily serves equipment buyers rather than direct prototype users. Shanghai Auran offers wide printer availability but shows lower customer retention, suggesting limited added value in post-sale support. For rapid-turnaround plastic prototypes, prioritize suppliers with sub-$1/centimeter pricing and ≤2-hour response times. For functional metal parts, verify machine-specific parameters such as laser power, chamber inerting, and HIP (Hot Isostatic Pressing) availability.

FAQs

How to verify 3D printer prototype service reliability?

Cross-check claimed printing technologies with sample work portfolios and request STL-to-part validation reports. Confirm compliance with material safety standards (RoHS, REACH) and verify post-processing capabilities through facility documentation or video audits.

What is the typical prototype lead time?

Standard delivery ranges from 5–12 days depending on complexity and finishing requirements. Express services can deliver basic FDM or SLA parts within 48–72 hours, excluding shipping. Add 3–5 days for complex assemblies or metal prints requiring heat treatment.

Can suppliers handle small-batch production?

Yes, most providers support MOQs of 1 piece, especially for resin and polymer prints. Unit costs decrease significantly at volumes above 50 units due to batch processing efficiencies in SLS and MJF systems.

Do suppliers offer free samples?

Sample policies vary. Some waive fees for qualified buyers committing to future orders. Others charge nominal fees (e.g., $0.01–$5 per part) to cover material and labor. Free samples are rare for metal or large-format prints.

How to initiate a custom prototype request?

Submit detailed specifications: preferred technology (FDM, SLA, SLS), material type, tolerances, surface finish, color, and any assembly or functional testing needs. Reputable suppliers respond with feasibility assessments and digital renderings within 24–72 hours.