Prototyping Service

Top sponsor listing

Top sponsor listing

HK

HK

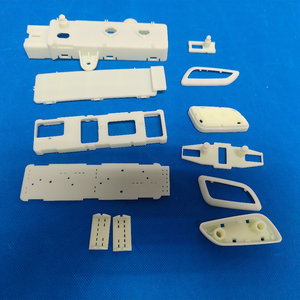

About prototyping service

Where to Find Prototyping Service Suppliers?

China leads global prototyping service provision, with concentrated supplier clusters in Zhejiang, Guangdong, and Shandong provinces offering distinct competitive advantages. Ningbo and Shanghai in Zhejiang host precision machining hubs, leveraging advanced CNC infrastructure and proximity to port logistics for rapid international shipment. Shenzhen in Guangdong specializes in integrated rapid prototyping solutions, combining 3D printing, sheet metal fabrication, and injection molding within compact supply ecosystems. Qingdao in Shandong has emerged as a center for cost-competitive additive manufacturing and investment casting services.

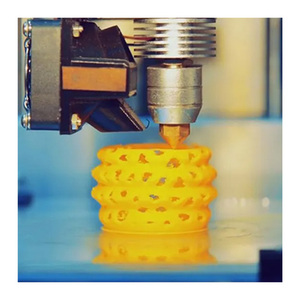

These industrial zones enable vertically integrated production—spanning design validation, material sourcing, multi-axis machining, and surface treatment—reducing lead times by 20–35% compared to decentralized suppliers. Buyers benefit from localized networks where tooling, metrology, and packaging vendors operate within 30km radii, supporting agile development cycles. Typical advantages include MOQs as low as 1 piece, average lead times of 7–14 days for machined prototypes, and 24–48 hour turnaround for 3D-printed models. Cost efficiency is further enhanced through economies of scale, with per-unit pricing up to 30% lower than Western counterparts for comparable tolerances (±0.05mm).

How to Choose Prototyping Service Suppliers?

Prioritize these verification criteria when evaluating potential partners:

Technical Capability Verification

Confirm access to multi-axis CNC machining (up to 5-axis), SLA/SLS/FDM 3D printing, and secondary processes such as wire cutting, anodizing, and color film coating. For high-precision applications, validate the presence of CMM inspection equipment and geometric dimensioning & tolerance (GD&T) compliance. Review digital design submission protocols, including compatibility with STEP, IGES, and STL formats.

Production Infrastructure Assessment

Evaluate operational scale and process integration:

- Facilities equipped with both subtractive (CNC lathes, milling centers) and additive (industrial-grade 3D printers) capabilities

- In-house mold-making or sheet metal forming capacity for downstream scalability

- Demonstrated experience with engineering materials including ABS, PLA, SS304/SS316, aluminum 6061/7075, titanium, and tool steels like 4140

- Surface treatment options: powder coating, plating, brushing, laser engraving, and custom labeling

Cross-reference technical claims with on-time delivery performance (target ≥96%) and response time (ideally ≤2 hours) to assess operational responsiveness.

Quality & Transaction Assurance

While formal ISO 9001 certification is not universally listed, prioritize suppliers demonstrating structured quality control via documented inspection reports, first-article testing, and photo verification workflows. Analyze reorder rates as a proxy for customer satisfaction—suppliers exceeding 25% indicate consistent output quality and service reliability. Use secure transaction mechanisms that support milestone-based payments, especially for complex prototypes requiring iterative revisions.

What Are the Best Prototyping Service Suppliers?

| Company Name | Main Services | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Verified Type |

|---|---|---|---|---|---|---|---|

| Ningbo Baozhen Machinery Co., Ltd. | Machining Services | Color, size, material, drawings, logo, packaging | 100% | 24% | ≤2h | US $70,000+ | Custom Manufacturer |

| Perfect Goods Prototype Co., Ltd. | Machining, 3D Printing (SLA/SLS/FDM) | Color, precision, material, lead time, packaging, logo | 96% | 23% | ≤3h | US $540,000+ | Custom Manufacturer |

| Huzhou Dear Industry Co., Ltd. | Injection Molding, Machining, Plastic Prototypes | Color, material (TPU, EPDM), hardness, 3D drawings, transparency | 100% | 50% | ≤6h | US $360,000+ | Multispecialty Supplier |

| Shenzhen Orhong Technology Co., Ltd. | CNC Machining, Sheet Metal, Casting, Moulds | Limited customization data available | 96% | 25% | ≤2h | US $20,000+ | Not Specified |

| 24K Investment (Qingdao) Co., Ltd. | 3D Printing, CNC, Sheet Metal, Moulds | Limited customization data available | 94% | 20% | ≤2h | US $10,000+ | Not Specified |

Performance Analysis

Huzhou Dear Industry stands out with a 50% reorder rate—the highest among listed suppliers—indicating strong client retention likely driven by specialized expertise in plastic injection molding and elastomer materials (EPDM, TPU). Perfect Goods Prototype Co., Ltd. demonstrates extensive service breadth across machining and industrial 3D printing, backed by significant online revenue (US $540,000+), suggesting robust order volume and process maturity. Ningbo Baozhen and Huzhou Dear both achieve perfect 100% on-time delivery, signaling reliable production planning and logistics execution. Shenzhen Orhong and 24K Investment offer broader fabrication portfolios but report lower reorder rates, which may reflect higher customer acquisition volatility or less standardized quality outcomes.

FAQs

What materials are commonly used in prototyping services?

Common materials include engineering plastics (ABS, PLA, PC, nylon), metals (aluminum 6061/7075, stainless steel 304/316, brass, bronze, 4140 steel), and elastomers (TPU, EPDM). Material selection depends on functional requirements such as strength, heat resistance, flexibility, and surface finish.

What is the typical minimum order quantity (MOQ)?

MOQs vary by process: CNC machining and 3D printing often support single-piece orders, while injection molding typically requires 2–100 units depending on mold complexity. Some suppliers quote per centimeter (e.g., $0.50/cm) for linear components.

How long does it take to receive a prototype?

Lead times range from 1–3 days for simple 3D-printed parts to 7–14 days for precision CNC-machined components. Complex assemblies or those requiring post-processing (anodizing, painting) may extend to 3 weeks. Rush services are available at select facilities.

Can suppliers assist with design optimization?

Yes, many providers offer design-for-manufacturability (DFM) feedback, particularly for CNC and injection molding projects. Submit detailed CAD files to receive manufacturability analysis, cost reduction suggestions, and tolerance validation prior to production.

Are surface treatments and finishing options available?

Standard finishing includes sanding, polishing, bead blasting, and anodizing. Custom options encompass powder coating, plating, laser etching, color film application, and branded packaging with custom labels and logos.