Rapid Prototyping Service Online

Top sponsor listing

Top sponsor listing

1/3

1/3

1/28

1/28

0

0

1/17

1/17

CN

CN

1/20

1/20

1/2

1/2

1/2

1/2

1/11

1/11

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/23

1/23

1/25

1/25

0

0

About rapid prototyping service online

Where to Find Rapid Prototyping Service Online Suppliers?

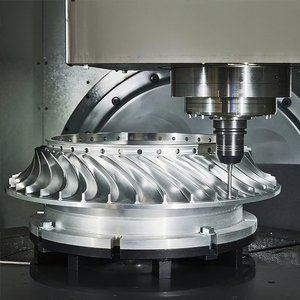

China remains the global epicenter for rapid prototyping services, with key industrial hubs in Shenzhen, Dongguan, and Xiamen offering advanced digital manufacturing ecosystems. These regions host vertically integrated facilities specializing in CNC machining, 3D printing, injection molding, and sheet metal fabrication—enabling seamless transition from concept to functional prototype within 3–7 days. Proximity to material suppliers and electronics manufacturers enhances agility, particularly for clients in consumer electronics, medical devices, and automotive R&D sectors.

The concentration of technical expertise and infrastructure supports high customization at competitive pricing. Digital quoting systems and online order tracking are standard among leading providers, allowing global buyers to submit CAD files and receive instant cost estimates. Economies of scale reduce per-unit costs by 20–40% compared to domestic prototyping in North America or Europe, while maintaining precision tolerances down to ±0.005mm. Lead times for simple CNC-machined parts average 5–8 business days, including shipping via express carriers.

How to Choose Rapid Prototyping Service Online Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Technical Capability Verification

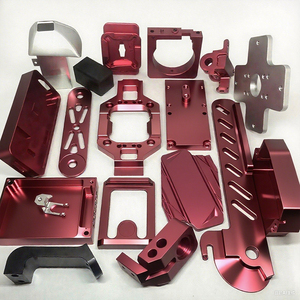

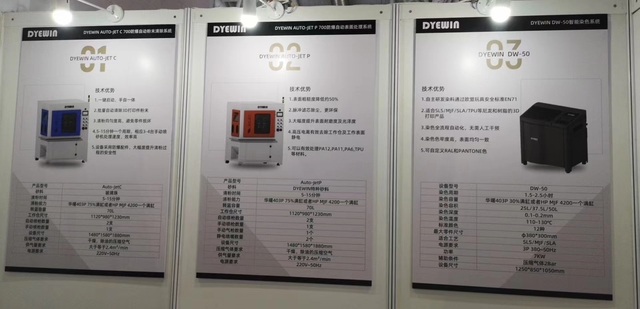

Confirm access to multi-axis CNC machines (3-, 4-, and 5-axis), industrial-grade 3D printing technologies (SLA, SLS, MJF), and secondary processing such as anodizing, painting, and assembly. Suppliers should support a broad range of engineering materials—including aluminum 6061/7075, stainless steel 303/316, brass, PEEK, ABS, and polycarbonate—to accommodate diverse functional testing requirements.

Quality & Operational Performance Metrics

Prioritize partners with documented quality management systems. Key indicators include:

- On-time delivery rate exceeding 95%

- Customer reorder rate above 40%

- Average response time under 4 hours

- Demonstrated capability for batch traceability and first-article inspection reports

Cross-reference performance tags with service consistency, especially for iterative development cycles requiring multiple revision rounds.

Customization & Transaction Security

Ensure suppliers offer full design-for-manufacturability (DFM) feedback, real-time file validation, and IP protection protocols. Evaluate their ability to handle color, surface finish, labeling, and packaging customizations. Use secure payment mechanisms with milestone-based releases, particularly for complex projects involving tooling or low-volume production integration.

What Are the Best Rapid Prototyping Service Online Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Strongd Model Technology Co., Ltd. | Machining Services (921), Moulds (161) | $50,000+ | 97% | 40% | ≤2h | Color, material, size, logo, packaging, label, graphic | 1–3 pieces | $25+ (varies by process) |

| Xiamen HYM Metal Products Co., Ltd. | Machining Services, CNC Milling | $2,600,000+ | 95% | 47% | ≤4h | Color, material, size, logo, packaging, label, graphic | 3 pieces | $0.10–$1.00 |

| Yuyao Taike Mold Factory | Machining Services (472), Moulds (295) | $20,000+ | 82% | 42% | ≤4h | Not specified | 1 acre* | $1.20–$4.60 |

| Shenzhen Qiangyida Hardware & Plastic Products Co., Ltd. | Machining Services (579) | $60,000+ | 72% | <15% | ≤5h | Not specified | 1 piece | $1.00–$30.00 |

| Yokan Precision Technology (Dongguan) Co., Ltd. | 5-Axis Custom Prototyping | Not available | 100% | No data | ≤11h | Color, material, size, logo, packaging, label, graphic | 1–10 pairs | $0.10–$60.00 |

Performance Analysis

Xiamen HYM leads in transaction volume and customer retention (47% reorder rate), indicating strong satisfaction in precision metal prototyping. Shenzhen Strongd excels in responsiveness (≤2h) and diversified service offerings, supported by a robust online presence. Yokan Precision achieves perfect on-time delivery despite limited public metrics, suggesting disciplined production planning for complex 5-axis components. Yuyao Taike demonstrates balanced capabilities in mold and machining services but shows moderate delivery performance (82%). Shenzhen Qiangyida, while offering low MOQs and flexible pricing, exhibits lower reliability metrics (72% on-time, <15% reorder), signaling potential operational inconsistencies.

FAQs

How to verify rapid prototyping service supplier reliability?

Assess verifiable performance data including on-time delivery rates, customer reorder frequency, and response latency. Request evidence of in-house machining capacity through facility videos or audit reports. Validate material certifications and post-processing capabilities relevant to your application’s mechanical or regulatory requirements.

What is the typical lead time for online rapid prototyping?

Standard lead times range from 3 to 7 days for CNC machining and 2 to 5 days for 3D printing after design approval. Express services (24–72 hour turnaround) are available from top-tier suppliers at a premium. Add 3–7 days for international air shipping depending on destination.

Do suppliers support small batch and custom orders?

Yes, most suppliers accept minimum orders as low as 1–3 units. Full customization—including material grade, surface treatment, branding, and packaging—is commonly offered, enabling startups and R&D teams to prototype without tooling investment.

Are there hidden costs in online prototyping quotes?

Transparent suppliers include machining, finishing, and basic inspection in initial pricing. Potential add-ons may include expedited handling, third-party testing, or complex geometry surcharges. Always confirm whether shipping, duties, and insurance are included in final invoicing.

How to ensure design confidentiality when sourcing online?

Select suppliers with published NDA policies and secure file transfer portals. Avoid sharing full product assemblies unless necessary; instead, upload only individual components requiring fabrication. Reputable providers log access and restrict data usage to production purposes only.