Rapid Prototyping Service

Top sponsor listing

Top sponsor listing

1/3

1/3

1/21

1/21

1/3

1/3

1/3

1/3

0

0

0

0

0

0

1/1

1/1

1/23

1/23

1/3

1/3

1/18

1/18

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/12

1/12

1/2

1/2

About rapid prototyping service

Where to Find Rapid Prototyping Service Suppliers?

China leads global rapid prototyping service provision, with key manufacturing hubs in Guangdong and Shandong provinces enabling high-efficiency production and export. Shenzhen and Dongguan in Guangdong host over 70% of China’s advanced additive manufacturing facilities, supported by dense networks of material suppliers, post-processing units, and logistics providers. Qingdao in Shandong has emerged as a center for industrial-grade metal printing and sheet metal integration, leveraging regional steel supply chains to reduce input costs by 10–18% compared to Western counterparts.

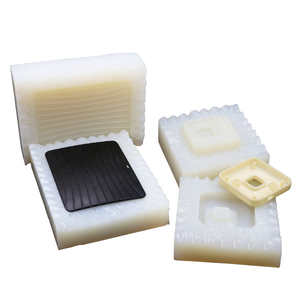

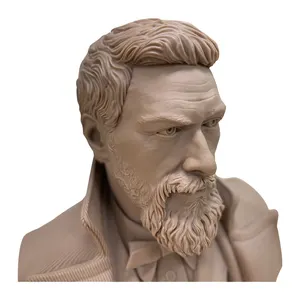

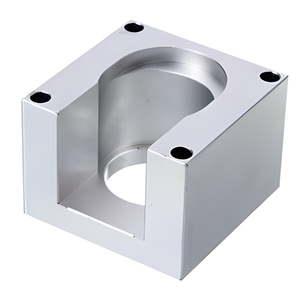

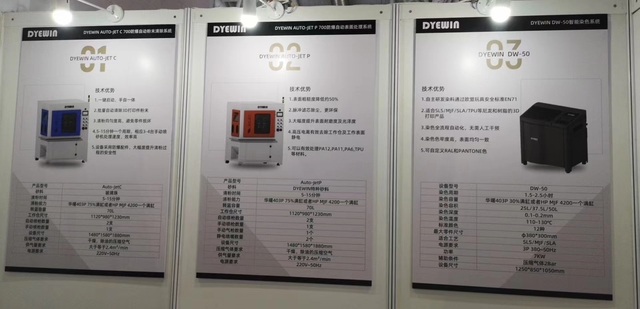

These clusters support vertically integrated operations—from CAD design and 3D printing to surface treatment and assembly—allowing lead times as short as 3–7 days for standard prototypes. Buyers benefit from localized ecosystems where machining, molding, and finishing services are accessible within 30km radii. Key advantages include low minimum order quantities (MOQs starting at 1 unit), pricing flexibility ($0.10–$6.90 per unit depending on complexity), and scalability for batch production up to 1,000+ units. Material diversity spans nylon, titanium, aluminum, SLA resin, TPU, and silicone, with multi-process options including SLM, MJF, vacuum casting, and CNC hybrid workflows.

How to Choose Rapid Prototyping Service Suppliers?

Apply these evaluation criteria when selecting qualified partners:

Technical Capability Verification

Confirm access to core technologies such as SLA, SLS, MJF, and metal powder bed fusion. Evaluate material certifications for aerospace-grade titanium, medical-grade resins, or RoHS-compliant plastics where applicable. Review equipment inventories that include industrial 3D printers (e.g., EOS, HP Multi Jet Fusion) and secondary processing tools like anodizing, electroplating, and dyeing stations.

Production Infrastructure Assessment

Assess operational scale through measurable indicators:

- Facility size supporting concurrent prototyping and small-batch production

- In-house capabilities across machining, molding, casting, and surface finishing

- Dedicated quality control teams using coordinate measuring machines (CMM) or optical scanning

Cross-reference supplier claims with on-time delivery rates (target ≥95%) and reorder frequency to validate reliability.

Transaction Risk Mitigation

Prioritize suppliers offering structured quality assurance protocols, including first-article inspection reports and digital traceability of print parameters. Utilize secure transaction mechanisms that link payment milestones to prototype validation. Request physical or digital samples—such as STL file compatibility tests or color-matched resin prints—to verify technical alignment before full commitment.

What Are the Best Rapid Prototyping Service Suppliers?

| Company Name | Location | Type | Main Processes | Materials Offered | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Js Add 3d Tech Co., Ltd. | Guangdong, CN | Custom Manufacturer | SLA, MJF, SLM, Vacuum Casting, Silicone Molding | Resin, Nylon, Titanium, Aluminum, Steel | 98% | ≤3h | US $80,000+ | 34% |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Guangdong, CN | Manufacturer | SLA, Dyeing, Painting, Machining | Plastic, Resin | 100% | ≤4h | US $30,000+ | 76% |

| Huzhou Dear Industry Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | SLA, SLS, Injection Molding, Machining | Resin, TPU, EPDM, ABS | 100% | ≤7h | US $340,000+ | 44% |

| 24K Investment (Qingdao) Co., Ltd. | Shandong, CN | Manufacturer | SLS, SLM, Machining, Sheet Metal, Casting | Nylon, Metal Alloys, ABS | 93% | ≤2h | US $8,000+ | 15% |

| Dongguan Yyi Technology Co., Ltd. | Guangdong, CN | Manufacturer | 3D Printing, Vacuum Casting, Machining | ABS, Nylon, Resin | 100% | ≤3h | US $30,000+ | 57% |

Performance Analysis

Guangzhou Gaojie and Dongguan Yyi demonstrate perfect on-time delivery records and strong customer retention (76% and 57% reorder rates respectively), indicating consistent process control and client satisfaction. Huzhou Dear Industry stands out in revenue volume (US $340,000+), suggesting extensive commercial deployment across diverse sectors. Shenzhen Js Add 3d Tech offers the broadest material and process range, making it suitable for complex multi-stage prototyping involving metal printing and surface engineering. While 24K Investment (Qingdao) has a lower reorder rate (15%), its sub-2-hour response time reflects high operational agility. Suppliers based in Guangdong dominate responsiveness and service breadth, whereas Shandong-based providers emphasize metal fabrication integration.

FAQs

How to verify rapid prototyping service supplier reliability?

Validate technical credentials through documented process controls, material data sheets, and sample traceability. Request evidence of quality management systems—even if formal ISO certification is absent. Analyze historical performance metrics such as on-time delivery rate, response speed, and repeat order frequency as proxies for operational stability.

What is the typical lead time for prototypes?

Standard prototypes are delivered within 3–7 working days after design approval. Complex builds requiring multi-material assembly, post-curing, or surface finishing may extend to 10–14 days. Expedited services (24–72 hours) are available from select suppliers for urgent R&D cycles.

Do suppliers accept custom design files?

Yes, all listed suppliers support common formats including STL, STEP, IGES, and DWG. Most offer free design for manufacturability (DFM) feedback within 24 hours. Ensure files specify tolerances, layer thickness, and finish requirements to avoid iteration delays.

What are common MOQ and pricing structures?

MOQs typically start at 1 unit, with per-unit pricing decreasing significantly at volumes above 100 pieces. Prices range from $0.10 for simple resin prints to $6.90 for high-precision metal components. Bulk orders often qualify for bundled post-processing discounts.

Can suppliers handle full product development cycles?

Top-tier providers offer end-to-end support from concept modeling to functional testing and limited-run production. Capabilities such as silicone molding for bridge tooling, vacuum casting for replication, and anodizing for durability enhance suitability for pre-commercialization stages.