3d Printing Batch Production

CN

CN

About 3d printing batch production

Where to Find 3D Printing Batch Production Suppliers?

China leads the global 3D printing batch production sector, with key supplier clusters in Zhejiang, Guangdong, and Yongkang offering specialized manufacturing ecosystems. Zhejiang-based suppliers, particularly around Hangzhou, focus on industrial-grade additive manufacturing using SLA, SLM, and DLP technologies, achieving high dimensional precision for engineering and automotive components. Guangdong’s Dongguan and Shenzhen regions specialize in consumer goods and rapid prototyping, integrating silicone molding and vacuum casting with 3D printing for low-volume plastic part production.

These hubs benefit from vertically integrated supply chains that combine material sourcing, post-processing (e.g., electroplating, polishing, painting), and digital design services within compact industrial zones. This integration enables lead times as short as 5–7 days for small-batch orders and supports scalable transitions from prototype to mid-volume runs. Buyers gain access to flexible production models with average unit costs ranging from $0.18 to $150, depending on material complexity, finishing requirements, and order volume. The presence of mature customization infrastructure allows for modifications in size, color, material type, and surface finish without significant tooling investment.

How to Choose 3D Printing Batch Production Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

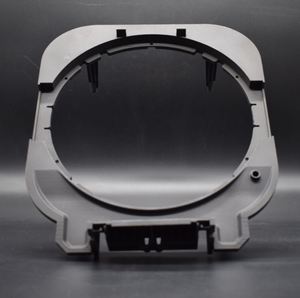

Verify compatibility with required printing technologies—SLA, SLS, FDM, DLP, or metal-based SLM/DMLS—based on end-use application. Confirm material options such as ABS, PLA, nylon, TPU, resin, titanium alloy, stainless steel, and photosensitive polymers. For functional parts, assess layer height control, dimensional accuracy, and structural integrity testing protocols.

Production & Customization Infrastructure

Evaluate the supplier’s capacity to handle requested batch sizes and customization scope. Key indicators include:

- Support for MOQs as low as 1 piece or scalable to 100+ units

- In-house post-processing capabilities: sandblasting, spray painting, electroplating, silk screening, rubber logo application, and packaging

- Digital workflow integration: 3D scanning, file rendering, reverse modeling, and real-time video confirmation

- Design flexibility for modifications in geometry, branding, color, and assembly integration

Quality & Responsiveness Metrics

Prioritize suppliers with documented on-time delivery rates exceeding 95%, response times under 3 hours, and reorder rates above 40%. These metrics reflect operational reliability and customer satisfaction. While formal certifications (e.g., ISO 9001) are not explicitly listed in available data, consistent performance indicators serve as proxy validations of quality management systems.

What Are the Best 3D Printing Batch Production Suppliers?

| Company Name | Supplier Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Unit Price | Max. Unit Price | Key Offerings |

|---|---|---|---|---|---|---|---|---|

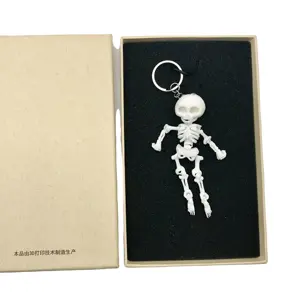

| Yongkang Qucheng Technology Co., Ltd. | Custom Manufacturer | US $230,000+ | 99% | ≤2h | 37% | $1.00 | $100.00 | Resin printing, full-color plating, TPU/nylon materials, custom engraving, environmental paint, fragile structure handling |

| Hangzhou Aoyi Trade Co., Ltd. | Multispecialty Supplier | US $180,000+ | 96% | ≤3h | 54% | $0.50 | $120.00 | SLA/DLP printing, metal 3D printing (SLM), cobalt-chromium, titanium, polyjet, sandblasting, special coatings |

| Torch Mold Limited | Multispecialty Supplier | US $130,000+ | 95% | ≤2h | 26% | $0.18 | $3.26 | ABS/PC/POM printing, rapid prototyping, CNC hybrid production, basic coloring and assembly |

| Nanfang Zengcai Technology Co., Ltd. | Not Specified | Data Unavailable | 100% | ≤5h | No Data | $1.00 | $10.00 | Multi-material printing, red wax models, toughness resin, small-batch metal printing |

| Dongguan Dafeng Model Co., Ltd. | Multispecialty Supplier | US $140,000+ | 87% | ≤5h | 41% | $1.35 | $148.00 | Action figures, vacuum casting, soft rubber parts, toy models, sheet metal hybrid fabrication |

Performance Analysis

Hangzhou Aoyi Trade stands out with the highest reorder rate (54%) and broadest material and technology portfolio, including advanced metal printing and specialty finishes. Yongkang Qucheng offers competitive pricing and strong responsiveness, ideal for detailed resin models and customized consumer products. Torch Mold Limited provides the lowest per-unit costs, making it suitable for cost-sensitive prototyping and simple plastic components. Nanfang Zengcai achieves perfect on-time delivery but lacks reorder data and revenue transparency, suggesting limited track record or niche engagement. Dongguan Dafeng specializes in collectibles and hybrid production but has a lower on-time delivery rate, indicating potential fulfillment risks for time-critical projects.

FAQs

How to verify 3D printing batch production supplier reliability?

Assess on-time delivery history, response speed, and reorder rate as primary performance indicators. Request sample parts to evaluate print quality, dimensional accuracy, and finish consistency. Confirm whether the supplier provides video validation of production stages and supports technical file formats (STL, STEP, IGES).

What is the typical lead time for batch 3D printed parts?

Standard small-batch orders (1–100 units) typically require 5–10 business days, including printing, post-processing, and quality checks. Complex geometries or multi-material assemblies may extend timelines to 14 days. Rush services with 3–5 day turnaround are available from select suppliers.

Can suppliers accommodate custom materials and finishes?

Yes, leading suppliers support extensive customization, including material selection (resin, ABS, nylon, TPU, metal alloys), surface treatments (glossy/matte finishes, electroplating, sandblasting), and branding options (engraving, silk screening, rubber logos). Confirm compatibility with intended use environment (e.g., UV resistance, mechanical stress).

What are common MOQs in 3D printing batch production?

MOQs vary widely: many suppliers accept single-piece orders for prototypes, while production batches start at 50–100 units. Some services, like vacuum casting for toys, require minimum runs of 100 pieces. Negotiate tiered pricing for volume scaling beyond initial batches.

How are quality issues resolved in cross-border transactions?

Establish clear acceptance criteria before production, including tolerance specifications and finish standards. Use platforms that offer dispute resolution mechanisms and partial payment releases upon sample approval. Video documentation of finished batches can serve as pre-shipment verification.