Mass Production Using 3d Printing

About mass production using 3d printing

Where to Find Suppliers for Mass Production Using 3D Printing?

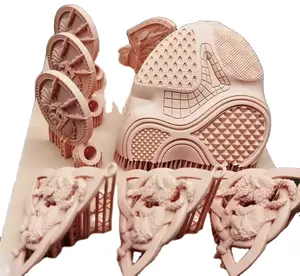

China leads in industrial-scale 3D printing services, with specialized supplier clusters concentrated in Guangdong, Dongguan, and Shanghai. These regions host vertically integrated facilities combining design, prototyping, and serial production capabilities—enabling scalable manufacturing of 3D printed products for global markets. Guangdong and Dongguan excel in polymer-based additive manufacturing (e.g., TPU, nylon, ABS), leveraging localized material supply chains and automation to reduce unit costs by up to 25% compared to Western counterparts. Shanghai focuses on high-end equipment and precision engineering, offering access to industrial-grade printers capable of metal sintering (SLM) and large-format builds.

The ecosystem supports both low-volume customization and mid-to-high volume runs through modular production lines. Key advantages include rapid iteration cycles (prototypes in 1–3 days), flexible batch sizing (MOQs from 1 piece), and integration of post-processing techniques such as sanding, painting, and assembly. Buyers benefit from proximity to component suppliers and logistics hubs, achieving lead times of 7–15 days for standard orders and expedited fulfillment for urgent requests.

How to Choose Suppliers for Mass Production Using 3D Printing?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

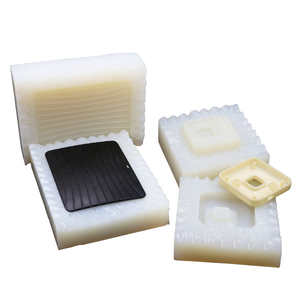

Confirm compatibility between supplier technology and your product requirements. Look for support of key processes: FDM, SLA, SLS, MJF, or metal SLM. Material expertise should align with application needs—TPU for flexible wearables, nylon for durable parts, resin for fine-detail models. Verify access to secondary operations like vacuum casting, CNC finishing, or overmolding for complex assemblies.

Production Scalability Assessment

Evaluate infrastructure indicators:

- Multiple printer banks supporting parallel job execution

- In-house design and file optimization teams for STL/DXF preparation

- Automated workflow management systems for batch tracking

Cross-reference online revenue data and reorder rates as proxies for sustained output capacity. Target suppliers with on-time delivery performance exceeding 95% and response times under 8 hours.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE, RoHS) are not explicitly listed in available profiles, prioritize suppliers demonstrating consistent quality via documented inspection protocols. Use secure payment mechanisms and request sample validation before full-scale orders. Analyze customer feedback patterns—reorder rates above 50% indicate satisfaction with dimensional accuracy, surface finish, and packaging consistency.

What Are the Leading Suppliers for Mass Production Using 3D Printing?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangdong Fohan Technology Co., Ltd. | Guangdong, CN | Machining Services, 3D Printers, Polymer Fabrication, Moulds | US $10,000+ | 86% | ≤8h | 60% | Limited (implied) | $0.70–$239 |

| Dongguan Yyi Technology Co., Ltd. | Dongguan, CN | Machining Services | US $40,000+ | 100% | ≤3h | 58% | Material, size, design | $1.29–$6.90 |

| Shanghai Auran Instrument & Equipment Co., Ltd. | Shanghai, CN | 3D Printers, Scanners, Laser Equipment | US $50,000+ | 100% | ≤2h | <15% | Equipment-focused | $400–$87,000 |

| Yuyao Bovon Trade Co., Ltd. | Zhejiang, CN | Custom 3D Printing, Multicolor ABS, Metal Prints | US $150,000+ | 100% | ≤10h | 21% | Color, material, size, logo, STL input | $0.10–$20 |

| HUITONG RAPID PROTOTYPE & SUPPLY COMPANY LIMITED | Guangdong, CN | Machining, Casting, Moulds, Rapid Prototyping | US $30,000+ | 100% | ≤4h | 25% | ABS, metal, clarity, large parts | $0.50–$19.90 |

Performance Analysis

Dongguan Yyi and Huitong stand out for reliability (100% on-time delivery) and competitive pricing for small-batch polymer parts. Yuyao Bovon offers the broadest customization scope and lowest per-unit prices ($0.10), making it suitable for consumer goods and promotional items. Guangdong Fohan demonstrates strong customer retention (60% reorder rate), suggesting consistent service quality despite a lower delivery rate. Shanghai Auran specializes in capital equipment rather than end-part production, targeting buyers seeking industrial 3D printers for in-house mass production. Prioritize suppliers with sub-5-hour response times and proven experience in your target material category when scaling beyond prototype stages.

FAQs

What is the typical MOQ for mass production using 3D printing?

Most suppliers offer MOQs starting at 1 piece, enabling scalable production from prototyping to volumes exceeding 1,000 units. Unit economics improve significantly at 100+ units due to batch processing efficiencies.

What are common lead times for 3D printed mass production?

Standard lead time ranges from 7 to 14 days after design approval. Expedited production (3–5 days) is available for simple geometries and readily available materials. Complex multi-part assemblies may require additional post-processing time.

Which materials are most cost-effective for scaled 3D printing?

Nylon (PA12), TPU, and ABS are widely used for functional parts due to durability and print efficiency. Resin suits high-detail applications like medical models or jewelry. For metals, stainless steel and titanium alloys via SLM are offered but carry higher per-part costs.

Can suppliers handle full product customization?

Yes, leading providers support full customization including geometry, color, texture, branding (logo imprinting), and packaging. Technical inputs required include STL files, dimensional specifications, tolerance requirements, and finish preferences.

How should buyers validate 3D print quality before bulk ordering?

Request physical or digital samples to assess layer resolution, warping, strength, and surface treatment. Specify critical dimensions for measurement verification. For regulatory-sensitive industries, confirm compliance with relevant standards (e.g., ISO/ASTM for medical or aerospace components).