3d Printing Is A Form Of Additive Manufacturing

1/7

1/7

1/8

1/8

1/21

1/21

1/23

1/23

1/23

1/23

1/18

1/18

About 3d printing is a form of additive manufacturing

Where to Source 3D Printing and Additive Manufacturing Suppliers?

China leads global production in 3D printing and additive manufacturing, with key supplier clusters concentrated in Guangdong and Zhejiang provinces. These regions host vertically integrated ecosystems combining material science, precision engineering, and digital fabrication services. Shenzhen and Dongguan specialize in industrial-grade metal 3D printing systems and on-demand part production, while Hangzhou has emerged as a hub for high-performance photopolymers used in dental and medical applications.

The concentration of technical expertise and supporting infrastructure enables rapid prototyping and scalable manufacturing. Suppliers benefit from co-located CNC machining, post-processing, and quality inspection facilities, reducing lead times by up to 40% compared to decentralized networks. Buyers access competitive pricing due to localized supply chains—particularly evident in stainless steel, tool steel, and resin-based outputs—with typical unit costs ranging from $0.50 to $19.90 for custom-printed components. Industrial 3D printer systems, meanwhile, are offered at scale starting from $88,000 per unit, reflecting cost advantages derived from domestic component sourcing and automated assembly lines.

How to Evaluate 3D Printing and Additive Manufacturing Suppliers?

Procurement decisions should be guided by structured assessment criteria focused on technical capability, operational reliability, and transactional transparency.

Production & Technical Capabilities

Assess the scope of available technologies: selective laser melting (SLM), stereolithography (SLA), and direct metal laser sintering (DMLS) are standard for high-precision metal parts. Confirm access to materials such as stainless steel, die steel, copper alloys, and medical-grade resins. Suppliers offering customization in color, packaging, and material formulation demonstrate higher process control. Minimum order quantities vary—from 1 piece for prototypes to 50+ units for batch production—indicating flexibility across project scales.

Quality Assurance and Compliance

While formal certifications (e.g., ISO 13485 for medical devices or ISO 9001) are not explicitly listed in available data, consistent on-time delivery rates of 100% across multiple suppliers suggest robust internal quality management. Response times under 10 hours—many ≤4h—indicate strong customer support infrastructure. Reorder rates, where reported, range from 15% to 80%, with top-tier performance observed among suppliers providing end-to-end machining and additive hybrid services.

Transaction and Risk Mitigation

Prioritize suppliers with verifiable online revenue (e.g., US $30,000+) and participation in third-party trade assurance programs. Demand sample validation before full-scale orders, particularly for critical applications in aerospace, automotive, or healthcare. Lead times for prototype delivery typically range from 7–15 days, depending on complexity and finishing requirements. For resin-based products, confirm biocompatibility testing if intended for dental or clinical use.

What Are the Leading 3D Printing and Additive Manufacturing Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization |

|---|---|---|---|---|---|---|---|---|

| HUITONG RAPID PROTOTYPE & SUPPLY COMPANY LIMITED | Machining, Casting, Moulds, Diesel Generators | $0.50–13.90 | 1 piece | 100% | ≤4h | 20% | US $30,000+ | Yes |

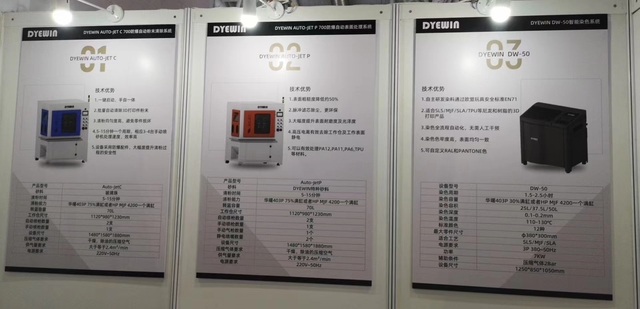

| Shenzhen Jinshi 3d Printing Technology Co., Ltd. | Industrial 3D Printers, SLA Systems | $88,200–480,000 | 1 unit/set | 100% | ≤7h | Not Available | Not Available | Yes |

| Pulesheng Technology (Guangdong) Co., Ltd. | SLM Services, Metal 3D Printing | $0.90–2.50 | 2–50 pieces | 100% | ≤10h | Not Available | US $100+ | Yes |

| Hangzhou Leyi New Material Technology Co., Ltd. | Dental Resins, Photocurable Materials | $40–180/kg | 1 kg | 100% | ≤1h | 15% | US $20,000+ | Color, Material, Packaging |

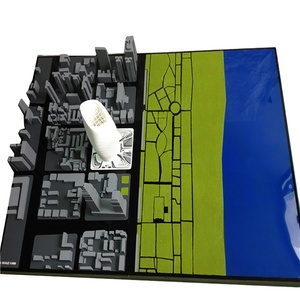

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Prototypes, Construction Models, SLS/SLA Parts | $0.69–5.80 | 1 unit | 100% | ≤5h | 80% | US $30,000+ | Yes |

Performance Analysis

HUITONG and Guangzhou Gaojie stand out for high reorder rates and proven export performance, suggesting strong customer satisfaction in prototyping and low-volume production. Shenzhen Jinshi specializes in capital equipment, offering industrial 3D printers suitable for large-scale manufacturing investments. Hangzhou Leyi excels in niche polymer materials, particularly for dental applications, supported by sub-one-hour response times and granular customization. Pulesheng offers competitively priced metal printing services but reports limited transaction volume, indicating potential scalability constraints. Buyers seeking high-reliability partners should prioritize suppliers with documented revenue streams and responsive communication channels.

FAQs

How to verify 3D printing supplier reliability?

Evaluate on-time delivery records, response speed, and verifiable sales volume. Request material test reports, especially for functional parts requiring thermal, mechanical, or biocompatible properties. Conduct virtual factory audits to confirm possession of SLM, SLA, or CNC post-processing capabilities.

What is the typical lead time for 3D printed parts?

Standard lead times range from 7–15 days for custom-printed metal or plastic components. Complex geometries or large-format prints may extend timelines to 20–25 days. Resin material shipments typically dispatch within 3–7 days after order confirmation.

Can suppliers provide customized materials or finishes?

Yes, several suppliers offer tailored solutions in material composition, surface finish, and post-processing (e.g., heat treatment, polishing). Hangzhou Leyi supports customization in resin color and packaging, while metal service providers allow alloy-specific builds based on application requirements.

Are samples available before bulk ordering?

Most suppliers accommodate sample requests. Costs vary by complexity—expect to pay between 30–70% of unit price for prototype validation. Sample production for functional metal parts typically takes 7–10 days, including inspection and shipping preparation.

What are common MOQs in additive manufacturing sourcing?

MOQs range from 1 piece for prototypes to 50+ units for cost-optimized batches. Material suppliers often require minimum purchases of 1kg. Low MOQs reflect the inherent flexibility of additive processes, making them ideal for R&D, small-series production, and spare parts fulfillment.