3d Printing Is Considered An Additive Technology

About 3d printing is considered an additive technology

Where to Find 3D Printing and Additive Technology Suppliers?

China is a global hub for 3D printing and additive manufacturing, with key supplier clusters in Guangdong and Shenzhen offering specialized expertise across industrial, medical, and consumer-grade applications. These regions host vertically integrated ecosystems combining design, prototyping, and production under one supply chain, enabling rapid turnaround and cost-efficient scaling. Shenzhen excels in electronics-integrated 3D printers and smart systems, while Guangdong focuses on industrial metal and polymer additive services, supporting aerospace, automotive, and medical device sectors.

The concentration of technical talent and component suppliers within these zones allows for agile manufacturing responses and reduced logistics overhead. Buyers benefit from localized access to CNC machining, mold-making, and post-processing services—critical for end-to-end part fabrication. Typical lead times range from 7–15 days for standard print orders and 30–45 days for custom machinery procurement. Cost advantages are significant, with production expenses averaging 20–40% below Western counterparts due to optimized labor and material sourcing networks.

How to Choose 3D Printing and Additive Technology Suppliers?

Selecting reliable partners requires structured evaluation across three core dimensions:

Technical Capability Verification

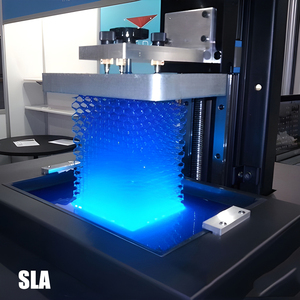

Confirm the supplier’s mastery of relevant additive processes: SLM (Selective Laser Melting), DMLS (Direct Metal Laser Sintering), MJF (Multi-Jet Fusion), or resin-based photopolymerization. For industrial clients, validate experience with engineering-grade materials such as stainless steel, titanium, nylon, and carbon fiber-reinforced polymers. Review product listings for evidence of high-resolution output, multi-material support, and thermal stability in final parts.

Production Infrastructure Assessment

Evaluate operational scale through measurable indicators:

- Facility size supporting both batch production and R&D activities

- In-house capabilities in machining, casting, and sheet metal fabrication for hybrid manufacturing

- Demonstrated investment in precision equipment, including laser sintering units and automated powder handling systems

Cross-reference online revenue data and reorder rates as proxies for market validation and service consistency.

Quality and Transaction Assurance

Prioritize suppliers with documented quality management practices. While formal ISO certification is not universally listed, assess performance metrics such as on-time delivery (>90% recommended) and response time (<8 hours acceptable). Leverage digital transaction safeguards where available, ensuring payment protection until inspection and acceptance. Request sample prints to verify dimensional accuracy, surface finish, and material integrity before full-scale engagement.

What Are the Best 3D Printing and Additive Technology Suppliers?

| Company Name | Main Products | Monthly Output Capacity | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Core Technologies | Customization Support |

|---|---|---|---|---|---|---|---|---|

| Anqing Wayne Hand Model Technology Co., Ltd. | Machining Services (1420) | High-volume prototyping & small-batch production | 92% | 46% | ≤2h | US $250,000+ | Metal 3D printing, Multi-Jet Fusion | Yes – supports complex geometries and functional prototypes |

| Shenzhen Eve-Innovations Technology Co., Ltd. | Inkjet Printers (170), 3D Printers (47) | Medium-scale printer assembly | 100% | 31% | ≤4h | US $30,000+ | Selfie and beverage 3D printing systems | Limited – focused on pre-configured smart printers |

| Guangdong Fohan Technology Co., Ltd. | Machining Services (279), Polymer (17) | Broad service portfolio with fast-turnaround capacity | 86% | 60% | ≤8h | US $10,000+ | SLM, Resin, Full-Color MJF | Yes – offers multi-material and full-color printing |

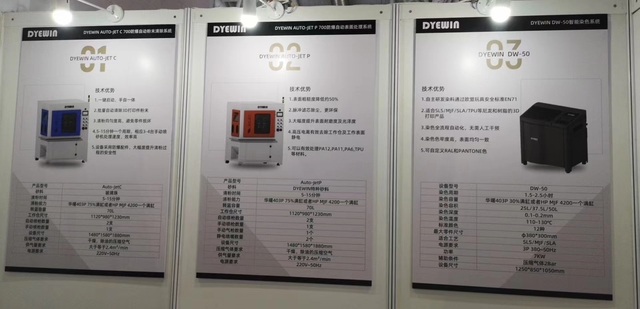

| Shenzhen Jinshi 3D Printing Technology Co., Ltd. | 3D Printers (144) | Industrial SLA systems – large-format production | 100% | - | ≤8h | - | SLA, High-Accuracy Large-Scale Printing | Yes – specializes in customized industrial printers |

| Shenzhen Mingda Technology Co., Ltd. | Industrial 3D printers, Additive Manufacturing Systems | High-capacity industrial unit production | 94% | 26% | ≤2h | US $1,000,000+ | FDM, Resin, Dual Nozzle, Heated Bed, UV Curing | Extensive – supports TPU, carbon fiber, dual extrusion, remote control, auto-leveling |

Performance Analysis

Anqing Wayne and Guangdong Fohan demonstrate strong service maturity with high reorder rates (46% and 60%, respectively), indicating consistent customer satisfaction in precision metal and polymer additive services. Shenzhen Eve-Innovations stands out for perfect on-time delivery but operates at lower customization levels, focusing on niche consumer applications. Shenzhen Jinshi and Mingda represent the industrial tier, offering high-value SLA and FDM systems priced up to $480,000 per unit, suitable for enterprise deployment. Mingda’s extensive customization options—including solvent-resistant, waterproof, and glowing filaments—make it ideal for specialized engineering use cases. Buyers seeking rapid iteration should prioritize suppliers with ≤2-hour response times and proven prototyping throughput.

FAQs

How to verify 3D printing supplier reliability?

Assess on-time delivery history, reorder rate, and response speed as behavioral indicators of operational discipline. Request sample parts to evaluate surface quality, dimensional accuracy, and material consistency. For industrial contracts, conduct virtual factory audits to confirm possession of laser sintering machines, controlled environment chambers, and post-processing stations.

What is the typical minimum order quantity (MOQ)?

Most suppliers list MOQ at 1 piece for prototype printing and sample testing. For printer hardware, MOQ is typically 1 unit or set. Bulk pricing applies at 5+ units, especially for desktop or industrial models.

Do suppliers support custom material specifications?

Advanced suppliers offer material flexibility, including carbon fiber, glass fiber, TPU, and biocompatible resins. Confirm compatibility with specific printers or service parameters before ordering. Some providers allow proprietary filament integration upon request.

Can 3D printing suppliers handle global shipping?

Yes, all listed suppliers export internationally. Shipping terms vary—confirm whether pricing is quoted FOB or includes CIF. Air freight is standard for samples (7–10 days transit); sea freight is economical for containerized machinery shipments.

Are free samples available?

Sample policies differ. Many suppliers provide small printed components at minimal cost ($0.70–$10) to cover material and labor. Free samples may be offered contingent on subsequent order commitments, particularly for high-volume buyers.