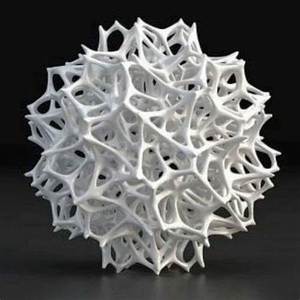

3d Systems Prototyping

Top sponsor listing

Top sponsor listing

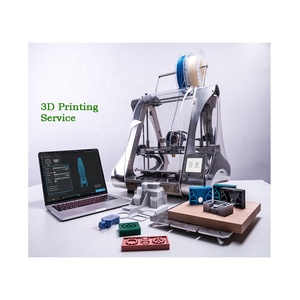

About 3d systems prototyping

Where to Find 3D Systems Prototyping Suppliers?

China remains a central hub for advanced prototyping services, with key suppliers concentrated in industrial regions such as Fujian, Shandong, Zhejiang, and Guangdong. These clusters host specialized manufacturers offering integrated rapid prototyping solutions, including SLA, SLS, FDM, CNC machining, and metal 3D printing. The proximity to material supply chains, precision engineering workshops, and export logistics infrastructure enables competitive pricing and scalable production.

Suppliers in Fuzhou and Shenzhen leverage vertically integrated facilities that combine design support, digital modeling, and multi-material fabrication under one roof. This integration reduces turnaround times for custom prototypes to 5–10 days on average. Companies like Fuzhou Jiahexing Machinery and Shenzhen Kunzhida Technology operate high-volume production lines capable of fulfilling both low-volume sampling and medium-batch manufacturing. With online transaction volumes exceeding US $180,000 annually per top-tier supplier, the ecosystem supports global buyers seeking reliable, scalable partnerships.

How to Choose 3D Systems Prototyping Suppliers?

Selecting the right partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

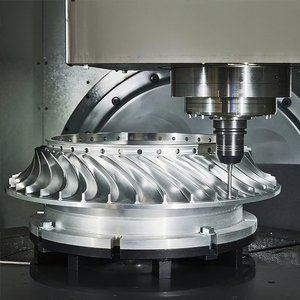

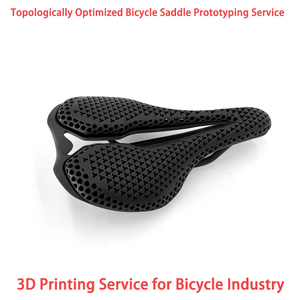

Confirm access to core prototyping technologies: stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), direct metal laser sintering (DMLS), and polyjet printing. Evaluate supported materials—Nylon (PA12), ABS, titanium, cobalt-chromium, photosensitive resins, and engineering-grade plastics. Suppliers should provide dimensional accuracy within ±0.05mm for high-precision applications and maintain layer resolution down to 25μm.

Production & Quality Assurance

Assess the following benchmarks:

- In-house machining and tooling capabilities (CNC, stamping, injection molding)

- Dedicated quality control protocols with documented inspection reports

- On-time delivery performance above 96%

- Reorder rates exceeding 25% indicating customer retention

- Response time under 4 hours for technical inquiries

Cross-reference service claims with verifiable metrics such as order fulfillment history and customization scope. High-performing suppliers offer full traceability from 3D file submission to final shipment.

Customization and Compliance

Ensure suppliers support STL, STEP, IGES, and 3D PDF formats and accept Pantone color matching, surface finishes (mirror polishing, sandblasting, electroplating), and post-processing options (painting, labeling, assembly). For regulated industries, verify compliance with ISO 9001 standards and request evidence of material certifications (e.g., RoHS, REACH) where applicable.

What Are the Best 3D Systems Prototyping Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Support |

|---|---|---|---|---|---|---|

| Fuzhou Jiahexing Machinery Co., Ltd. | Machining Services (806), Moulds (114), Sheet Metal Fabrication (99) | 100% | ≤2h | 21% | US $110,000+ | Sheet metal, plastic injection, mold design, 3D drawings, material selection |

| 24K Investment (Qingdao) Co., Ltd. | Machining Services (166), Other Fabrication Services (6) | 94% | ≤2h | 20% | US $10,000+ | Limited to basic 3D printing configurations |

| HUITONG RAPID PROTOTYPE & SUPPLY COMPANY LIMITED | Machining Services (184), Casting Services (36), Other Fabrication Services (51) | 100% | ≤4h | 25% | US $30,000+ | SLM metal printing, high-temp Inconel, SLS nylon, precision sintering |

| Hangzhou Aoyi Trade Co., Ltd. | Machining Services (extensive), Die Steel, Resin Printing | 96% | ≤3h | 56% | US $180,000+ | Full-color printing, DLP/DLS, TPEE, PEBA, swappable battery designs, software compatibility |

| Shenzhen Kunzhida Technology Co., Ltd. | Set-top Box (100), Machining Services (45) | 98% | ≤6h | 27% | US $20,000+ | SLA/SLS/FDM, plastic product development, rapid iteration support |

Performance Analysis

Hangzhou Aoyi stands out with the highest reorder rate (56%) and annual revenue (US $180,000+), reflecting strong client satisfaction and broad customization capabilities. Fuzhou Jiahexing and HUITONG lead in on-time delivery (100%), making them ideal for time-sensitive projects. While 24K Investment offers entry-level pricing, its lower reorder rate and limited service breadth suggest niche applicability. Shenzhen Kunzhida provides balanced performance with fast turnaround and solid technical coverage, particularly for plastic-based prototypes.

FAQs

What is the typical MOQ for 3D systems prototyping services?

Minimum order quantities vary by technology and material. Most suppliers accept orders starting at 1 piece for 3D printed parts, with some requiring 10–100 centimeters for linear print runs. No mold costs are typically charged for single-unit prototypes.

How long does prototyping take from file submission to delivery?

Standard lead times range from 3 to 7 days for non-metallic prints and 7 to 14 days for metal-based or multi-process prototypes. Complex assemblies or surface treatments may extend timelines by 3–5 days. Express services (24–72 hour turnaround) are available from select providers.

Do suppliers support file format conversion and design optimization?

Yes, leading suppliers offer free 3D file review and conversion (STL, STEP, IGES). Some provide design-for-manufacturability feedback to improve print success rates, reduce material use, and enhance structural integrity prior to production.

Are samples available before bulk production?

Prototypes serve as functional samples. Many suppliers include one-off prototype creation in project quotes, especially for new clients. Costs are often credited toward larger production runs. Sample validation is recommended for critical components involving fit, thermal resistance, or mechanical stress.

What payment and transaction protections are available?

Buyers can utilize secure payment methods with escrow protection, ensuring funds are released only after quality verification. Reputable suppliers participate in verified trade programs, offer dispute resolution mechanisms, and provide detailed production updates throughout the workflow.