4 Axis Cnc Milling Machine Wholesaler

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/23

1/23

1/20

1/20

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/24

1/24

About 4 axis cnc milling machine wholesaler

Where to Find 4 Axis CNC Milling Machine Wholesalers?

China remains the global epicenter for 4-axis CNC milling machine production, with Shandong province emerging as a dominant hub for industrial-grade machining centers. The region hosts vertically integrated manufacturing clusters in Tengzhou and Jinan, where suppliers benefit from localized access to precision casting foundries, linear guide producers, and servo motor assembly plants. This integration reduces component procurement lead times by up to 30% compared to decentralized supply models.

These ecosystems support rapid scalability, enabling wholesalers to fulfill bulk orders within standardized timelines of 30–45 days. Average production facilities span 5,000–25,000 m², housing automated assembly lines capable of producing 50–100 units monthly across multiple configurations. Suppliers leverage economies of scale to offer competitive pricing, with entry-level desktop models starting below $1,200 and heavy-duty vertical machining centers exceeding $36,000. Buyers gain access to diverse product tiers—from compact benchtop routers to fully automated 4-axis vertical mills—supported by modular design frameworks that facilitate customization.

How to Choose 4 Axis CNC Milling Machine Wholesalers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm equipment specifications align with application requirements. Key parameters include spindle power (ranging 3–15 kW), table size (400x200 mm to 1300x700 mm), and control system type (e.g., Syntec, Fanuc, or Mach3-compatible). Evaluate optional features such as automatic tool changers, thermal stabilization systems, chip conveyors, and rotary axis integration. For high-precision applications, verify inclusion of absolute position sensors, optical rulers, and rollerless gear drives.

Production & Quality Assurance Infrastructure

Assess supplier capabilities through objective benchmarks:

- Minimum factory area of 3,000 m² indicating volume capacity

- In-house machining and assembly lines (not OEM rebranding)

- Dedicated quality inspection protocols including run-in testing and geometric accuracy validation

- Compliance with ISO 9001 standards; CE certification for EU market access

Cross-reference on-time delivery rates (target ≥95%) and response times (≤2 hours preferred) as indicators of operational efficiency.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to ensure shipment verification prior to fund release. Prioritize suppliers with documented after-sales support structures, including remote diagnostics, spare parts availability, and operator training. Request sample units for performance benchmarking—particularly spindle runout, surface finish consistency, and positional repeatability—before committing to large orders.

What Are the Leading 4 Axis CNC Milling Machine Wholesalers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) |

|---|---|---|---|---|---|---|---|

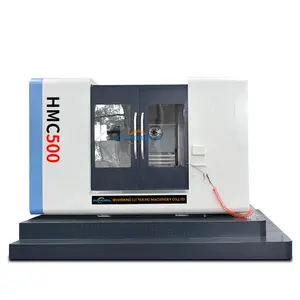

| Shandong Lu Young Machinery Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, Band Saw Machines | US $210,000+ | 100% | ≤2h | 20% | N/A |

| Shandong Youtai Machine Tool Manufacturing Co., Ltd. | Shandong, CN | CNC Milling Machines, Drilling Machines, Accessories | US $120,000+ | 100% | ≤1h | <15% | $16,199–33,000 |

| Tengzhou Believe Machinery Co., Ltd. | Shandong, CN | CNC Milling Machines, Manual Mills, Band Saws | US $10,000+ | 100% | ≤3h | 25% | $4,590–27,680 |

| Shandong Vv Machine Co,.ltd | Shandong, CN | Machining Centre, Manual Lathe, Drilling Machines | US $6,000+ | 33% | ≤1h | <15% | $18,000–36,000 |

| Shenzhen Fundar Technology Limited | Guangdong, CN | Laser Engravers, Wood Routers, Mini CNC Machines | US $90,000+ | 93% | ≤9h | <15% | $599–2,000 |

Performance Analysis

Shandong-based suppliers dominate reliability metrics, with three of five achieving 100% on-time delivery. Shandong Lu Young leads in transaction volume (US$210,000+), suggesting strong export throughput and client trust. Tengzhou Believe Machinery offers the broadest price spectrum ($4,590–$27,680), catering to both entry-level workshops and mid-tier manufacturers. In contrast, Shandong Vv Machine reports only 33% on-time delivery despite aggressive pricing, signaling potential fulfillment risks. Shenzhen Fundar specializes in compact, sub-$2,000 units ideal for prototyping and light engraving, though longer response times (≤9h) may delay urgent procurement cycles.

FAQs

What certifications should 4-axis CNC milling machine suppliers have?

ISO 9001 is essential for quality management verification. CE marking is required for compliance in European markets, ensuring adherence to safety, health, and environmental standards. Buyers should request copies of test reports for electrical systems, emergency stop functions, and mechanical guarding.

What is the typical MOQ and lead time?

Most wholesalers set a minimum order quantity of 1 set, accommodating small buyers and pilot projects. Standard lead times range from 30 to 45 days post-deposit, depending on machine complexity and customization level. Expedited builds may reduce timelines by 7–10 days at additional cost.

Can suppliers customize 4-axis CNC milling machines?

Yes, leading suppliers offer configuration options including controller brands (Syntec, Siemens, Mitsubishi), spindle types (BT40, CAT40), coolant systems, tool changers, and safety enclosures. Custom firmware, workholding fixtures, and integration with rotary tables are available upon request, typically requiring 3D drawings or technical specifications for quotation.

Do suppliers provide technical support and training?

Reputable manufacturers include basic remote support via video guidance or TeamViewer-assisted setup. Some offer on-site commissioning services at additional cost. Documentation packages typically include operation manuals, wiring diagrams, and maintenance schedules. Advanced training programs covering G-code programming and preventive maintenance are available from select suppliers.

How are machines packaged and shipped internationally?

Machines are securely crated in seaworthy wooden cases with anti-vibration padding and moisture protection. FOB terms are standard, though CIF arrangements can be negotiated. Sea freight is most economical for full-container loads; air shipping is viable for single units requiring urgent delivery, albeit at significantly higher cost.