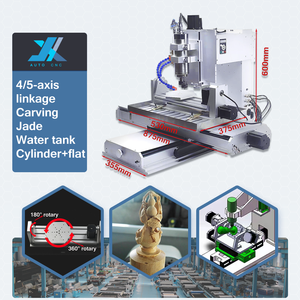

5 Axis Cnc Milling Machine Desktop Distributor

1/12

1/12

1/18

1/18

1/36

1/36

1/10

1/10

1/9

1/9

1/21

1/21

About 5 axis cnc milling machine desktop distributor

Where to Find 5-Axis CNC Milling Machine Desktop Suppliers?

China remains the global epicenter for compact and precision-focused 5-axis CNC milling machine production, with key supplier clusters concentrated in Shandong, Shaanxi, and Guangdong provinces. These regions host vertically integrated manufacturing ecosystems that combine advanced machining centers, electronics assembly, and motion control system integration under one supply chain. Shandong’s Jinan and Qingdao zones specialize in desktop-scale CNC routers and milling systems, supported by localized steel fabrication and linear guide rail suppliers, reducing component lead times by up to 25%. Shaanxi’s Xi’an industrial corridor leverages aerospace-grade engineering expertise, enabling high-precision spindle calibration and multi-axis synchronization critical for micro-machining applications.

Suppliers in these hubs operate from facilities ranging from 400m² to over 270,000m², supporting scalable production from hobbyist-grade units to industrial desktop models. The proximity of subsystem vendors—such as servo motor, controller, and ball screw manufacturers—enables rapid prototyping and customization. Buyers benefit from lead times averaging 15–30 days for standard configurations, with costs typically 30–50% lower than equivalent European or North American-built machines due to optimized labor and logistics efficiency.

How to Choose 5-Axis CNC Milling Machine Desktop Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer true simultaneous 5-axis control (not just indexed 5-axis) for complex contouring tasks. Evaluate spindle specifications: high-speed spindles (≥24,000 RPM) are essential for fine-detail work in materials like aluminum, titanium, or composites. Request firmware and control software details—compatibility with industry-standard platforms (e.g., Mach4, Siemens, or proprietary closed-loop systems) impacts long-term usability.

Production Infrastructure Assessment

Prioritize suppliers with documented R&D capabilities and in-house assembly lines. Key indicators include:

- Facility size exceeding 1,000m² indicating volume capacity

- In-house testing of motion accuracy (repeatability ≤ ±0.01mm)

- Integration of linear guideways, harmonic drives, or direct-drive rotary axes

Cross-reference online revenue data and on-time delivery rates (>95%) to assess operational stability.

Quality & Transaction Assurance

While formal ISO 9001 certification is not universally listed, consistent on-time delivery (100% among top-tier suppliers in this dataset) and low reorder rates suggest process discipline. Use secure payment mechanisms and request pre-shipment inspection rights. Sample testing should include dry-run cycle validation and surface finish benchmarking on target materials (e.g., aluminum 6061, PEEK, or acrylic).

What Are the Best 5-Axis CNC Milling Machine Desktop Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shaanxi Jingwei Hongbo Cnc Equipment Co., Ltd. | Shaanxi, CN | Machining Centre, CNC Milling Machines | $19,999–74,000 | 1 unit | 100% | ≤1h | US $100+ | <15% |

| Jinan Taihe Cnc Equipment Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, Wood Routers | $6,500–20,000 | 1 set | 100% | ≤1h | Not specified | Not available |

| Jinan Remax Machinery Technology Co., Ltd. | Shandong, CN | Mini ATC CNC, Desktop 5-Axis | $1,100–17,857 | 1 set | 100% | ≤2h | US $10,000+ | <15% |

| Shenzhen Richon Industry Co., Ltd. | Guangdong, CN | Customizable CNC Mills, VMC Series | $4,000–23,000 | 1 set | 88% | ≤2h | US $290,000+ | 15% |

| Shandong Jx Auto Cnc Machinery Co., Ltd. | Shandong, CN | Wood Routers, Foam & Mould CNC | $1,000–10,000 | 1–30 sets | 100% | ≤4h | US $270,000+ | 50% |

Performance Analysis

Shaanxi Jingwei Hongbo leads in high-end desktop 5-axis solutions, offering premium models above $70,000 with tight response times (≤1h) and proven delivery reliability. Jinan Taihe provides mid-range versatility across vertical and gantry configurations, ideal for mixed-material workshops. Jinan Remax stands out for entry-level precision, with sub-$5,000 options suitable for educational or prototyping environments. Shenzhen Richon enables extensive customization—from spindle type to control interface—but exhibits a lower on-time delivery rate (88%), warranting closer shipment monitoring. Shandong Jx Auto targets niche applications in wood and foam machining, reflected in its high reorder rate (50%), suggesting strong customer satisfaction in specialized sectors despite longer response cycles.

FAQs

What is the typical MOQ for desktop 5-axis CNC milling machines?

Most suppliers list a minimum order quantity of 1 unit or set, facilitating procurement for SMEs, research labs, and pilot production. However, some budget models require bulk orders (e.g., 30 sets at $1,000–1,200/unit), particularly for OEM distribution.

How long does production and shipping take?

Standard lead time ranges from 15 to 30 days after order confirmation. Air freight delivery adds 5–10 days; sea freight (FCL/LCL) takes 25–40 days depending on destination. Expedited builds may be available for urgent requests, subject to supplier capacity.

Can suppliers customize 5-axis desktop CNC machines?

Yes, customization is widely offered, including spindle speed, tool changer (ATC) integration, control software, work envelope size, and material compatibility. Shenzhen Richon explicitly lists multiple configurable parameters such as linear guides, servo motors, and high-speed spindles.

Are CE or ISO certifications common among these suppliers?

Certifications are not explicitly stated in the provided data. Buyers must request compliance documentation directly, especially for EU or North American market entry. Pre-shipment inspections should verify electromagnetic compatibility (EMC), safety interlocks, and emergency stop functionality per CE/OSHA standards.

Do suppliers offer technical support and training?

While not quantified in the dataset, responsive suppliers (≤2h average reply time) typically provide remote setup assistance, wiring diagrams, and basic operation manuals. Advanced training or on-site support may require negotiated service agreements or third-party contracts.