5 Axis Cnc China

CN

CN

CN

CN

About 5 axis cnc china

Where to Find 5-Axis CNC Machine Suppliers in China?

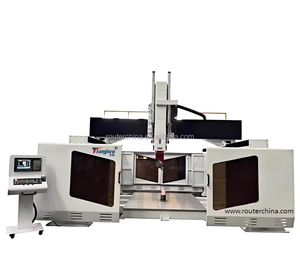

China remains a dominant force in the global 5-axis CNC machine manufacturing sector, with key industrial clusters concentrated in Shandong and Jiangsu provinces. These regions host vertically integrated production ecosystems that combine precision component sourcing, advanced machining capabilities, and streamlined logistics. Shandong, in particular, has emerged as a hub for mid-to-high-end CNC equipment, supported by localized supply chains for ball screws, linear guides, and servo systems—reducing material costs by 15–25% compared to non-specialized regions.

The clustering effect enables suppliers to offer competitive pricing and faster turnaround times, with standard lead times averaging 30–45 days for ready-to-ship models. Buyers benefit from access to mature technical networks where engineering teams, tooling specialists, and quality control units operate within compact geographic zones—ensuring rapid prototyping and efficient after-sales support. Economies of scale allow Chinese manufacturers to deliver high-precision 5-axis systems at price points ranging from $14,000 to $150,000, depending on configuration, controller type, and application specificity.

How to Choose 5-Axis CNC Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Prioritize suppliers demonstrating adherence to international quality standards such as ISO 9001. For export markets, verify CE marking or equivalent regulatory compliance to ensure machine safety and customs clearance eligibility. Request documentation on spindle accuracy (typically ±0.005mm), positioning repeatability, and control system integration (e.g., Syntec, Fanuc).

Production Capability Assessment

Evaluate core manufacturing competencies through objective metrics:

- Minimum factory area exceeding 3,000m² to support full-cycle production

- In-house assembly lines with dedicated testing bays for 5-axis synchronization

- Integration of high-precision components: THK/Hiwin linear guides, Yaskawa/Siemens servo drives

- On-site R&D capacity confirmed via product iteration history and customization logs

Cross-reference supplier claims with verifiable performance data such as on-time delivery rates (target ≥97%) and reorder frequency.

Transaction Risk Mitigation

Utilize secure payment mechanisms like escrow services to align financial release with physical inspection at destination. Analyze historical transaction patterns, focusing on response speed (ideally ≤2 hours) and dispute resolution transparency. Conduct pre-shipment inspections to validate machine calibration, ATC functionality, and coolant/mist management systems before final acceptance.

What Are the Leading 5-Axis CNC Machine Suppliers in China?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Jinan Spower Machinery Technology Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $180,000+ | 100% | ≤2h | 58% | $16,899–78,000 | Yes |

| Shandong Lu Young Machinery Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $120,000+ | 100% | ≤2h | 40% | $17,000–52,000 | Yes |

| Jinan Hongda Cnc Equipment Co., Ltd. | Shandong, CN | Not specified | US $950,000+ | 100% | ≤1h | 30% | $4,700–18,000 | No |

| Shandong Yijin Cnc Machine Tool Co., Ltd. | Shandong, CN | Not specified | US $40,000+ | 100% | ≤1h | 50% | $14,000–49,999 | No |

| Jinan Quick-Fulltek CNC Machinery Co., Ltd. | Shandong, CN | Not specified | US $30,000+ | 100% | ≤9h | <15% | $14,000–150,000 | Yes |

Performance Analysis

Jinan Spower Machinery stands out with the highest reorder rate (58%) and extensive customization options, including tool changers, safety systems, and spindle drive configurations—indicating strong customer retention and engineering flexibility. Shandong Yijin demonstrates competitive responsiveness (≤1h) and consistent delivery performance, while Jinan Hongda reports the highest online revenue (US $950,000+), suggesting significant order volume despite limited customization offerings. Suppliers like Jinan Quick-Fulltek cater to niche applications such as composite and foam machining, with premium models reaching $150,000, reflecting specialization over volume. Buyers seeking high-accuracy metal milling should prioritize vendors offering Fanuc or Syntec controllers and dual-axis rotary tables.

FAQs

How to verify 5-axis CNC machine supplier reliability?

Validate certifications through official registries and request audit trails covering component sourcing, assembly procedures, and final testing protocols. Examine customer feedback for consistency in machine accuracy, after-sales service, and software compatibility. Video-based facility tours can confirm in-house production versus trading operations.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 set, enabling low-volume procurement. Standard lead times range from 30 to 45 days post-deposit, with expedited builds possible for an additional fee. Complex customizations may extend delivery by 15–20 days.

Do suppliers offer customization for 5-axis CNC machines?

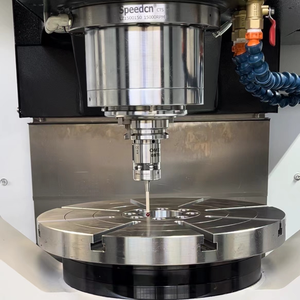

Yes, select manufacturers provide modular upgrades including automatic tool changers (ATC), CCD cameras for alignment, mist collectors, heavy-duty spindles, and t-slot table configurations. Customization depth varies—verify compatibility with target materials (metal, wood, composites) and required tolerances before ordering.

Can 5-axis CNC machines be shipped internationally?

All listed suppliers support global shipping via sea freight (FCL/LCL) with FOB or CIF terms. Confirm packaging standards (wooden crate with anti-vibration mounts) and import compliance requirements for destination countries, particularly regarding electrical specifications and machine safety regulations.

Is sample testing available before bulk purchase?

While full-machine samples are uncommon due to size and cost, suppliers often allow test-cut demonstrations either on-site or via live video. Some offer trial units under rental or consignment arrangements. Always request machining reports showing surface finish, tolerance achievement, and multi-axis coordination accuracy.