China Cnc Zone 5 Axis

CN

CN

CN

CN

About china cnc zone 5 axis

Where to Find 5-Axis CNC Machine Suppliers in China?

China's 5-axis CNC machining sector is anchored in industrial hubs across Shandong and Guangdong provinces, where integrated manufacturing ecosystems support high-precision machine tool production. Shandong, home to key suppliers like Yantai and Tengzhou-based enterprises, benefits from a long-standing metalworking tradition and proximity to steel and casting supply chains, reducing component procurement lead times by up to 25%. These clusters feature vertically aligned operations—from structural casting and linear guide integration to final calibration—enabling end-to-end control over machine build quality.

The region’s supplier density fosters competitive pricing without compromising technical capability, with standard 5-axis vertical machining centers (VMCs) priced between $14,800 and $33,000 for entry to mid-tier configurations. Buyers gain access to facilities equipped with in-house assembly lines and testing zones that validate axis synchronization, spindle runout, and thermal stability. Lead times for standard units typically range from 30 to 45 days, with expedited builds possible for pre-engineered models. The concentration of technical talent and component vendors within 50km radii enhances responsiveness and supports rapid prototyping or customization cycles.

How to Choose 5-Axis CNC Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical and Quality Assurance

Confirm adherence to international standards such as ISO 9001 for quality management. For export markets, CE marking indicates compliance with European safety and electromagnetic compatibility directives. Request documentation on spindle precision (runout ≤0.005mm), ball screw accuracy (C3 class or higher), and five-axis联动 (simultaneous motion) validation through laser interferometer reports. Verify controller brands (e.g., Syntec, Fanuc, Siemens) as indicators of system reliability and serviceability.

Production and Engineering Capacity

Assess infrastructure maturity using these benchmarks:

- Minimum factory area exceeding 3,000m² to support dedicated machining, assembly, and testing zones

- In-house capabilities for critical subsystems: spindle mounting, rotary table integration, and ATC (Automatic Tool Changer) calibration

- Dedicated R&D or application engineering teams supporting customization (e.g., work envelope expansion, coolant mist systems, CCD alignment)

Cross-reference claimed delivery performance—target suppliers with ≥90% on-time shipment rates—and evaluate response times (≤2 hours preferred) as proxies for operational discipline.

Risk Mitigation and Transaction Security

Utilize secure payment mechanisms such as escrow or letter of credit for initial orders. Prioritize suppliers with verifiable online transaction histories and third-party trade assurance participation. Conduct pre-shipment inspections either independently or via recognized agencies to verify mechanical accuracy, control functionality, and safety interlocks. Request sample runs with customer-provided CAD/CAM files to benchmark surface finish and dimensional repeatability before full-scale procurement.

What Are the Leading 5-Axis CNC Machine Suppliers in China?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Capability | Price Range (USD) |

|---|---|---|---|---|---|---|---|

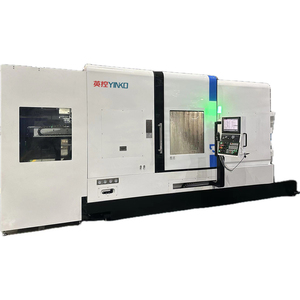

| Yantai Hongyi Electromechanical Equipment Co., Ltd. | Machining Centre, CNC Lathe, Hydraulic Cylinders | 55% | ≤4h | <15% | $60,000+ | Limited | $14,820–$18,230 |

| Tengzhou Enxin Cnc Machinery Co., Ltd. | CNC Milling Machines, Machining Centre, Manual Mills | 100% | ≤1h | <15% | Not disclosed | Moderate | $19,600–$33,000 |

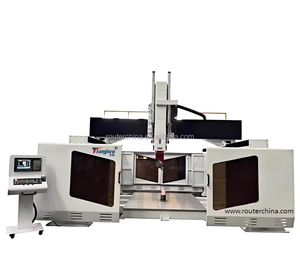

| Jinan Spower Machinery Technology Co., Ltd. | 5-Axis CNC Router, Woodworking Center, PTP Machining | 100% | ≤1h | 58% | $230,000+ | High | $12,599–$52,803 |

| Jinan Truster Cnc Equipment Co., Ltd. | 5-Axis Metal & Foam Milling, Mould Carving | 92% | ≤2h | 40% | $240,000+ | High | $23,700–$47,000 |

| Jinan Tianjiao Machinery Manufacture Co., Ltd. | Wood Carving, 3D CNC Router, Plasma Cutters | Not available | ≤5h | <15% | $700+ | Variable | $6,890–$130,000 |

Performance Analysis

Tengzhou Enxin and Jinan Spower demonstrate strong operational reliability with 100% on-time delivery and sub-2-hour response times, making them suitable for time-sensitive procurement. Jinan Truster stands out with a 40% reorder rate and extensive customization options, indicating robust customer satisfaction and engineering flexibility. While Yantai Hongyi offers competitively priced entry-level machines, its lower reorder rate and delivery performance suggest potential scalability limitations. Jinan Tianjiao presents a wide price spectrum but lacks verifiable transaction volume and delivery metrics, warranting due diligence for high-value purchases. Suppliers with documented customization features—such as tool changers, active safety systems, and multi-material processing—are better positioned for specialized applications in aerospace, mold-making, or medical device manufacturing.

FAQs

What certifications should 5-axis CNC suppliers have?

Essential certifications include ISO 9001 for quality management and CE for compliance with EU safety, health, and environmental standards. Suppliers exporting to North America may also comply with ANSI/B11 safety codes. Request test certificates for spindle vibration, geometric accuracy (per GB/T 17421.1 or ISO 230 standards), and electrical safety.

What is the typical MOQ and lead time?

Minimum Order Quantity is typically 1 set, accommodating both trial purchases and bulk deployments. Standard lead times range from 30 to 45 days after deposit confirmation. Customized models with non-standard controllers or work envelopes may require 60+ days.

Can suppliers customize 5-axis CNC machines?

Yes, many suppliers offer configuration options including spindle type (BT40/BT50), ATC capacity (8–24 tools), worktable size, control systems (Syntec, Mach3, Fanuc), and auxiliary systems like oil mist collectors or probing. High-end customization—such as dual pallet changers or integrated automation—is available from suppliers with proven engineering teams.

Do suppliers provide technical support and training?

Most established suppliers offer remote diagnostics, installation manuals, and video-guided commissioning. On-site support may be available at additional cost. Training typically covers basic operation, tool setting, and maintenance procedures, with advanced programming support dependent on supplier expertise.

How are 5-axis CNC machines packaged and shipped?

Machines are secured in seaworthy plywood crates with anti-vibration mounts and moisture protection. FOB terms are common, with buyers responsible for freight and insurance. Full container loads (20' or 40') are optimal for cost efficiency. Pre-shipment inspection reports and packing lists are standard inclusions.