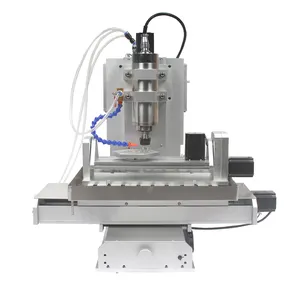

5 Axis Cnc Universal Machining Center

1/23

1/23

1/10

1/10

CN

CN

1/34

1/34

1/22

1/22

1/15

1/15

1/20

1/20

1/19

1/19

CN

CN

1/11

1/11

1/24

1/24

About 5 axis cnc universal machining center

Where to Find 5 Axis CNC Universal Machining Center Suppliers?

China remains the central hub for 5 axis CNC universal machining center production, with key manufacturing clusters concentrated in Shenzhen and Tengzhou. These regions host vertically integrated facilities that combine precision engineering, advanced automation, and streamlined logistics to support global export demand. Shenzhen-based suppliers leverage proximity to high-tech R&D centers and component suppliers, enabling rapid prototyping and integration of digital control systems. Tengzhou, located in Shandong Province, specializes in heavy-duty machine tool manufacturing, benefiting from a mature ecosystem of castings, spindles, and linear guides that reduce material costs by up to 18% compared to Western alternatives.

The industrial clusters offer scalability through consolidated supply chains—many suppliers operate within 30km of critical subsystem vendors, ensuring shorter lead times (typically 25–40 days for standard configurations). Buyers benefit from localized production ecosystems capable of fulfilling both low-volume prototype orders and large-scale procurement contracts. Cost efficiency is further enhanced by access to in-house CNC fabrication, heat treatment, and assembly lines, reducing dependency on external subcontractors and improving quality traceability across production stages.

How to Choose 5 Axis CNC Universal Machining Center Suppliers?

Selecting reliable suppliers requires a structured evaluation based on technical capability, operational performance, and transactional transparency.

Technical and Production Capability

Assess whether suppliers possess in-house machining infrastructure for core components such as rotary tables, spindles, and control systems. Prioritize manufacturers with dedicated R&D teams focused on kinematic optimization and error compensation algorithms essential for 5-axis motion accuracy. Verify presence of precision assembly environments and laser calibration systems to ensure repeatability within ±0.005mm.

Quality Assurance and Compliance

While explicit certification data is limited in available records, evaluate compliance indirectly through delivery reliability and customer reorder rates. Target suppliers with documented quality management practices, including spindle runout testing, thermal stability checks, and dynamic load balancing. For international buyers, confirm adherence to CE or equivalent safety standards for electrical systems and mechanical guarding before deployment.

Customization and Engineering Support

Several suppliers offer configurable options including tool post design, color coding, material compatibility (aluminum, steel, composites), and software interface preferences. Confirm availability of CAD/CAM integration support, especially for dental, mold, and aerospace applications requiring complex surface interpolation. Request 3D models or virtual factory walkthroughs to validate build processes prior to order placement.

Transaction and Risk Mitigation

Utilize secure payment mechanisms such as escrow services until equipment passes site acceptance tests. Analyze supplier performance metrics: prioritize those with on-time delivery rates exceeding 93%, response times under 3 hours, and reorder rates above 30%. Conduct sample validation to benchmark surface finish quality, positional accuracy, and cycle time consistency against ISO 230-2 and ASME B5.54 standards.

What Are the Best 5 Axis CNC Universal Machining Center Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Price Range (USD) | Specialization |

|---|---|---|---|---|---|---|---|

| Shenzhen Scotle Technology Ltd. | Wood Routers, Laser Welders, CNC Milling Machines | 92% | 33% | ≤3h | US $70,000+ | $2,250–7,100 | Benchtop & hobby-grade 5-axis mills |

| Shenzhen Camdent Medical Technology Co., Limited | Dental Milling Machines, Oral Therapy Equipment | 100% | 53% | ≤2h | US $70,000+ | $8,000–38,000 | CAD/CAM dental prosthetics milling |

| Shenzhen Integrity Industry Co., Ltd. | Universal Mold Processing Centers, Metal Mills | 93% | 15% | ≤2h | US $120,000+ | $3,480–77,350 | Industrial mold & die machining |

| Hainan Meierkang Biomedical Industry Development Co., Ltd. | Dental Milling Machines, Biomedical Equipment | 87% | <15% | ≤3h | US $50,000+ | $11,500–18,990 | Chairside dental restoration systems |

| Tengzhou Kerui Meike Machine Tool Co., Ltd. | Machining Centres, CNC Lathes, Manual Mills | 100% | <15% | ≤1h | US $400+ | $16,200–51,800 | Vertical 5-axis machining centers |

Performance Analysis

Shenzhen Camdent leads in customer retention (53% reorder rate) and punctuality (100% on-time delivery), indicating strong after-sales support and process reliability—critical for medical device manufacturers requiring consistent output. Tengzhou Kerui Meike matches 100% delivery performance with the fastest average response time (≤1h), making it suitable for urgent procurement cycles despite lower repeat order volume. Shenzhen Integrity offers the widest price and application range, including high-end mold processing centers priced over $77,000, reflecting investment in larger-scale production infrastructure. Scotle Technology provides entry-level benchtop units below $2,500, ideal for educational institutions or small workshops exploring 5-axis capabilities. Hainan Meierkang focuses narrowly on wet-cutting dental mills but exhibits moderate delivery risk (87%) and low reorder frequency.

FAQs

How to verify 5 axis CNC machining center supplier reliability?

Cross-check stated delivery performance with historical transaction data. Request evidence of spindle testing reports, backlash measurements, and controller firmware versions. Evaluate responsiveness consistency and technical depth in communications as proxies for engineering competence.

What is the typical lead time for standard 5-axis CNC machines?

Standard units are typically delivered within 30–45 days after order confirmation. Customized models with specialized spindles or control interfaces may require 50–70 days, depending on component availability and calibration requirements.

Do suppliers offer customization for industrial applications?

Yes, multiple suppliers provide configuration options for tooling, work envelope dimensions, coolant systems, and automation readiness. Confirm compatibility with industry-specific software (e.g., Mastercam, HyperMill) and fixture integration prior to ordering.

What are common MOQ and pricing structures?

Minimum Order Quantity is universally set at 1 set, allowing flexibility for pilot purchases. Prices range from $2,250 for miniaturized desktop units to over $77,000 for full-scale mold processing centers, reflecting differences in rigidity, travel, and spindle power.

Can 5-axis CNC machines be shipped internationally?

All listed suppliers support global shipping. Confirm Incoterms (FOB vs. CIF), packaging specifications (wooden crate with anti-vibration mounts), and import compliance documentation (electrical schematics, CE declarations if applicable) before finalizing orders. Sea freight is recommended for heavy machinery to minimize transport costs.