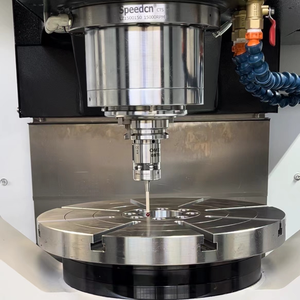

5 Axis Vertical Machining Center Factory

CN

CN

CN

CN

CN

CN

About 5 axis vertical machining center factory

Where to Find 5-Axis Vertical Machining Center Suppliers?

China remains the global epicenter for 5-axis vertical machining center production, with key manufacturing clusters in Shaanxi, Shandong, and Guangdong provinces. These regions host vertically integrated factories equipped with in-house CNC component manufacturing, structural heat treatment, and precision assembly lines. The concentration of technical suppliers—ranging from servo motor providers to linear guide producers—within 100km radii enables rapid prototyping and scalable production.

Suppliers in these hubs benefit from mature industrial ecosystems that support full-cycle development, from casting and welding to final calibration. This integration reduces lead times by up to 30% compared to fragmented supply models. Buyers can expect standard delivery windows of 45–60 days for non-custom units, with cost advantages averaging 20–35% over European or North American equivalents due to lower overhead and localized material sourcing.

How to Choose 5-Axis Vertical Machining Center Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Verify adherence to international quality standards such as ISO 9001. While not always explicitly stated, suppliers demonstrating consistent on-time delivery (≥100%) and third-party transaction coverage are more likely to maintain internal quality management systems. For export compliance, ensure machine designs meet CE or equivalent safety regulations, particularly in control system layout and emergency stop integration.

Production Infrastructure Assessment

Evaluate core capabilities through verifiable metrics:

- Confirmed ownership of end-to-end production lines (casting, machining, assembly)

- In-house R&D capacity indicated by customization options (e.g., control systems, tool changers)

- Integration of high-rigidity structural design and thermal compensation technologies

Cross-reference response time (≤3 hours preferred) and reorder rates as indirect indicators of operational stability and customer satisfaction.

Procurement Risk Mitigation

Utilize secure payment frameworks that tie disbursements to verified milestones. Prioritize suppliers offering sample testing or remote factory audits via video walkthroughs. Request detailed specifications—including spindle accuracy (±0.003mm typical), positioning repeatability (±0.005mm), and controller compatibility (Fanuc, Siemens, Mitsubishi)—before order placement.

What Are the Best 5-Axis Vertical Machining Center Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Capability | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shaanxi Jingwei Hongbo Cnc Equipment Co., Ltd. | Shaanxi, CN | Machining Centre, CNC Milling Machines | US $100+ | 100% | ≤1h | <15% | Limited (Own production line noted) | $19,998–48,500 |

| Dongguan Ruian Precision Machinery Co., Ltd. | Guangdong, CN | CNC Lathe, Machining Centre | Not specified | 100% | ≤2h | Not available | Moderate (Multiple model variants) | $24,000–125,888 |

| Tengzhou Hipow Machinery Co., Ltd. | Shandong, CN | VMC850, Gantry Milling, Servo Motorized Systems | US $230,000+ | 100% | ≤2h | 66% | High (Servo motors, color, rigidity, packaging) | $7,200–34,000 |

| Shandong Classic Machine Tool Co., Ltd. | Shandong, CN | Heavy-Duty, High-Precision Machining Centers | US $430,000+ | 100% | ≤3h | 25% | High (Control systems, tool changers, configurations) | $13,865–50,724 |

| Yuxi Hengyao Machinery Co., Ltd. | Yunnan, CN | High-Precision, Large-Load CNC Machining Centers | Not specified | 100% | ≤7h | Not available | Premium (DERBY-EVO series, high-load models) | $66,500–585,000 |

Performance Analysis

Tengzhou Hipow stands out for high customer retention (66% reorder rate) and extensive customization, despite mid-range pricing. Shandong Classic demonstrates strong commercial traction with over $430,000 in online revenue and broad configuration flexibility. Yuxi Hengyao targets premium industrial applications with six-figure units, suggesting investment-grade durability and precision engineering. Dongguan Ruian and Shaanxi Jingwei offer competitive entry-level pricing with proven delivery reliability. Response efficiency is strongest among northern and eastern China suppliers, with three of five responding within two hours.

FAQs

How to verify 5-axis machining center supplier credibility?

Request documentation of quality control processes, including spindle runout tests, ballbar measurements, and geometric accuracy reports. Confirm whether machines undergo 72-hour continuous dry-run testing prior to shipment. Validate company credentials through business licenses and export records.

What is the typical minimum order quantity (MOQ)?

All listed suppliers specify an MOQ of 1 unit, enabling low-volume procurement for testing or specialized applications. This flexibility supports pilot deployments and integration trials without bulk commitment.

Are customization options widely available?

Yes, multiple suppliers offer configurable elements such as CNC controllers (Fanuc/Siemens/Mitsubishi), tool changer types, work envelope dimensions, and rigidity enhancements. High-end models may include automated pallet changers or coolant-through-spindle features upon request.

What lead times should buyers expect?

Standard units typically ship within 45–60 days after order confirmation. Custom-built models require 70–90 days depending on complexity. Expedited builds may be negotiable for premium orders with confirmed production slot availability.

Do suppliers support global shipping and installation?

Most suppliers facilitate FOB or CIF shipping arrangements and provide basic installation manuals. For turnkey deployment, inquire about optional technician dispatch services, though associated costs (travel, lodging, duration) must be factored into total project budgets.