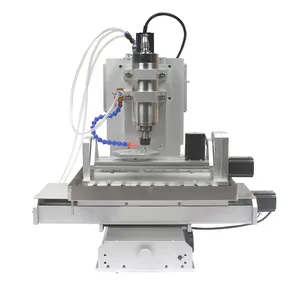

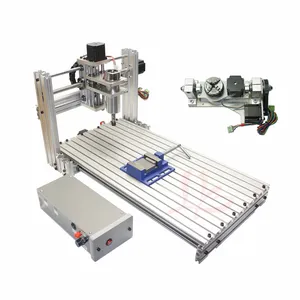

5 Axis Cnc Diy Kit

About 5 axis cnc diy kit

Where to Find 5 Axis CNC DIY Kit Suppliers?

China remains the central hub for 5 axis CNC DIY kit manufacturing, with key production clusters in Guangdong and Shandong provinces. Shenzhen-based suppliers dominate the mid-tier market, offering modular kits designed for hobbyists and small-scale workshops. These facilities leverage localized access to precision components—linear guides, stepper motors, and control systems—enabling rapid assembly and competitive pricing. In contrast, Shandong-based manufacturers focus on industrial-grade solutions, integrating advanced features such as automatic tool changers (ATC) and dual-control systems, often tailored for woodworking and metal engraving applications.

The ecosystem benefits from vertically integrated supply chains, where structural aluminum extrusions, drive mechanisms, and electronics are sourced within regional networks, reducing lead times by 20–30% compared to offshore alternatives. Buyers gain access to flexible production models capable of fulfilling single-unit DIY orders or batch configurations. Average delivery windows range from 15–30 days for standard kits, with customization extending timelines by up to two weeks. This infrastructure supports cost efficiency, with entry-level 5-axis kits starting below $300 and high-performance variants exceeding $28,000.

How to Choose 5 Axis CNC DIY Kit Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm compatibility with common control software (e.g., Mach3, GRBL) and support for analog or PWM signal integration. For advanced users, verify inclusion of MPG (Manual Pulse Generator) support and multi-axis synchronization. Suppliers should provide clear documentation on motor torque ratings, spindle power (typically 500W–2.2kW), and frame rigidity—critical for minimizing vibration in 5-axis operations.

Production & Customization Capacity

Assess supplier flexibility through available customization options:

- Material compatibility: aluminum, wood, PVC, or composite substrates

- Frame size scalability: from mini 3020 formats to large 3220 work envelopes

- Electrical system options: 5V DC, 24V stepper drivers, or hybrid configurations

- Branding and labeling services for resellers

Cross-reference product listings with response time and reorder rate metrics to gauge operational responsiveness. Prioritize suppliers with ≤6-hour average response times and proven order fulfillment consistency.

Quality & Transaction Assurance

While formal certifications (ISO, CE) are infrequently cited in DIY-focused listings, buyers should request evidence of functional testing per unit. Utilize secure payment frameworks that release funds post-delivery verification. Evaluate online revenue indicators and on-time delivery rates—values above 90% correlate with reliable logistics execution. Sample testing is recommended to assess build quality, calibration accuracy, and software integration before scaling procurement.

What Are the Best 5 Axis CNC DIY Kit Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Liyang Engraving Equipment Co., Ltd. | Guangdong, CN | Wood Routers (103) | US $20,000+ | 92% | ≤6h | <15% | $335–1,977 | No |

| Shenzhen Scotle Technology Ltd. | Guangdong, CN | Wood Routers (217) | US $80,000+ | 92% | ≤3h | 31% | $2,250–2,700 | No |

| Shandong UBO CNC Machinery Co., Ltd. | Shandong, CN | Not specified | US $600+ | - | ≤1h | <15% | $8,000–28,500 | Yes |

| Shenzhen Liyang Welding Equipment Co., Ltd. | Guangdong, CN | Wood Routers (248) | US $20,000+ | 100% | ≤5h | 15% | $308–1,187 | No |

Performance Analysis

Shenzhen-based suppliers offer strong value for entry-level and mid-range buyers, with Shenzhen Scotle Technology demonstrating higher customer retention (31% reorder rate) and faster response cycles (≤3h). Shenzhen Liyang Welding Equipment stands out with a verified 100% on-time delivery rate, indicating robust logistics management despite moderate reorder volume. In contrast, Shandong UBO CNC Machinery targets industrial clients with premium, customizable solutions—pricing reflects complexity, with ATC-equipped models exceeding $29,000. Although its online revenue is lower, the company offers full customization across color, size, and branding, making it suitable for OEM integrations. Buyers seeking cost-effective, plug-and-play kits should prioritize Guangdong-based vendors; those requiring scalable, engineered systems may benefit from Shandong’s specialized offerings.

FAQs

How to verify 5 axis CNC DIY kit supplier reliability?

Evaluate on-time delivery performance, response latency, and transaction volume. Request product specifications, wiring diagrams, and software compatibility details. Validate claims through sample orders and independent review analysis focusing on mechanical stability and electronic reliability.

What is the typical lead time for 5 axis CNC DIY kits?

Standard kits ship within 15–20 days after order confirmation. Customized or high-power configurations may require 30–45 days, depending on component availability and calibration requirements.

Can suppliers accommodate bulk or OEM orders?

Yes, many suppliers support OEM branding and packaging modifications. Bulk pricing typically applies at 5+ units, with discounts ranging from 5–15% based on volume. Confirm minimum order quantities (MOQ) and tooling costs for customized variants.

Do 5 axis CNC DIY kits include controllers and software?

Most kits include basic motion controllers and support common open-source firmware (e.g., GRBL, Mach3). High-end models may feature proprietary control panels with MPG integration. Verify software compatibility with intended CAD/CAM workflows prior to purchase.

Are spare parts and technical support available post-purchase?

Supplier support varies. Higher-revenue vendors typically offer schematic access and replacement components (e.g., stepper drivers, limit switches). Proactive buyers should confirm support channels and part availability before finalizing orders.