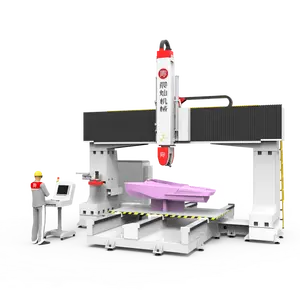

5 Axis Machining Explained

Top sponsor listing

Top sponsor listing

1/18

1/18

1/9

1/9

1/15

1/15

1/20

1/20

About 5 axis machining explained

Where to Find 5-Axis Machining Service Suppliers?

China remains the global epicenter for precision 5-axis CNC machining services, with concentrated supplier clusters in Guangdong Province—particularly Dongguan and Zhongshan—driving innovation and scale. These regions host vertically integrated manufacturing ecosystems that combine advanced multi-axis machining centers with secondary processing capabilities such as anodizing, sheet metal fabrication, and casting. Proximity to material suppliers and port infrastructure enables lead times averaging 15–25 days for custom prototypes and 30–45 days for production batches.

The industrial density in these zones supports rapid iteration and low minimum order quantities (MOQs), often starting at 1 piece. Suppliers leverage localized supply chains to reduce component costs by 20–30% compared to Western counterparts, while maintaining compatibility with international quality standards. Buyers benefit from access to high-precision engineering talent, in-house tooling design, and scalable production lines capable of handling titanium, aluminum, steel, and engineered plastics.

How to Choose 5-Axis Machining Service Suppliers?

Selecting a reliable partner requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm availability of full 5-axis simultaneous machining (not 3+2 axis positioning) through equipment lists or facility videos. Prioritize suppliers offering tolerance ranges down to ±0.005mm and surface finishes below Ra 0.8μm. Demand documentation of process controls for complex geometries, especially for aerospace, medical, or automotive applications.

Production Infrastructure Assessment

Evaluate key indicators of scalability and consistency:

- Minimum 3+ years in precision machining with documented project portfolios

- In-house engineering support for DFM (Design for Manufacturing) feedback

- Integrated post-processing options: anodizing, plating, laser engraving, packaging

- Cross-reference on-time delivery performance (target ≥95%) with response time metrics (≤6 hours preferred)

Quality & Transaction Assurance

While formal ISO 9001 certification is not universally listed, consistent on-time delivery and repeat order rates signal operational maturity. Use incremental ordering strategies—start with prototype runs—to validate dimensional accuracy and communication efficiency. Leverage digital drawing validation (3D STEP files, PDF markups) before committing to volume production.

What Are the Best 5-Axis Machining Service Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Holy Precision Manufacturing Co., Limited (zhongshan) | Zhongshan, CN | Machining Services, Sheet Metal Fabrication, Casting, Moulds | US $310,000+ | 84% | ≤6h | 41% | Steel, titanium, anodizing, 3D drawings, labeling, coatings | 1 piece |

| Dongguan Mengyuanze Technology Co., Ltd. | Dongguan, CN | Machining Services, Sheet Metal Fabrication, Casting | US $4,000+ | 100% | ≤1h | 25% | Limited material data; strong responsiveness | 1 piece |

| Dongguan Kaizhida Precision Machinery Co., Ltd. | Dongguan, CN | Machining Services | - | 100% | ≤1h | - | Titanium, aluminum, mechanical components | 1 piece |

| Dongguan Jiangjun Hardware Co., Ltd. | Dongguan, CN | Machining Services, Aluminum Profiles, Copper Strips | US $2,000+ | 66% | ≤1h | 25% | Anodizing, CNC turning, size customization | 1–10 pieces |

| Xiamen Changyuan Jinsheng Technology Co., Ltd. | Xiamen, CN | Machining Services, Sheet Metal Fabrication, Casting | US $700+ | 100% | ≤3h | - | Broad price band ($0.10–9.99), high flexibility | 1 piece |

Performance Analysis

Dongguan-based suppliers dominate responsiveness, with three achieving sub-3-hour average reply times and perfect on-time delivery records. Holy Precision stands out for highest reorder rate (41%) and revenue volume, suggesting strong customer retention despite slightly lower punctuality (84%). In contrast, Dongguan Mengyuanze and Kaizhida achieve 100% on-time performance with immediate response cycles, ideal for urgent prototyping. Xiamen Changyuan Jinsheng offers widest pricing flexibility, accommodating both ultra-low-cost and high-precision workloads. Note that Jiangjun Hardware has the lowest on-time delivery rate (66%), indicating potential capacity constraints despite technical capability.

FAQs

How to verify 5-axis machining supplier reliability?

Request sample parts with inspection reports showing GD&T compliance. Validate machine park claims via video tours or timestamped photos. Analyze transaction history through verifiable shipment records and client references, particularly for regulated industries.

What is the typical lead time for 5-axis machined parts?

Standard prototypes take 7–12 days; production orders require 15–30 days depending on complexity and finishing requirements. Add 5–10 days for surface treatments like hard anodizing or chrome plating.

Can suppliers handle titanium and other difficult-to-machine materials?

Yes, several suppliers explicitly list titanium machining capabilities with optimized toolpaths and cooling protocols. Confirm spindle RPM (≥12,000) and tooling strategy (carbide or ceramic inserts) for efficient material removal.

Do 5-axis machining providers offer design support?

Most offer basic DFM analysis using 3D CAD models (STEP, IGES). High-performing suppliers return annotated drawings within 24–48 hours identifying potential manufacturability issues, wall thickness concerns, or tolerance stack-ups.

Are there hidden costs in low-unit-price quotes?

Potential add-ons include fixture design, non-standard materials, tight tolerances (<±0.005mm), and special packaging. Always confirm final pricing includes all post-processing, QA documentation, and export preparation.