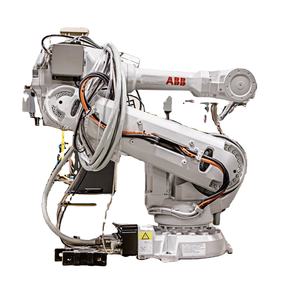

Abb Reconditioned Robots

CN

CN

Top sponsor listing

Top sponsor listing

1/5

1/5

CN

CN

1/14

1/14

1/5

1/5

CN

CN

1/12

1/12

1/14

1/14

1/31

1/31

About abb reconditioned robots

Where to Find ABB Reconditioned Robots Suppliers?

China serves as a central hub for the reconditioning and distribution of industrial automation equipment, including ABB reconditioned robots. Key supplier clusters are located in Guangdong, Shanghai, and Shandong provinces—regions known for their advanced robotics ecosystems and proximity to original equipment service networks. Guangzhou and Shanghai host specialized facilities focused on precision diagnostics and refurbishment, while Shandong has emerged as a center for cost-effective remanufacturing supported by mature mechanical engineering supply chains.

These industrial zones offer integrated capabilities spanning robotic system testing, component replacement, firmware updates, and performance validation. Suppliers benefit from access to skilled technical labor pools and localized sourcing of motors, gearboxes, and control panels, enabling faster turnaround times. Buyers can expect lead times averaging 15–30 days for tested units, with pricing typically 40–60% below new equivalents. The concentration of expertise allows for scalable operations, supporting both single-unit replacements and fleet upgrades across automotive, metal fabrication, and logistics sectors.

How to Choose ABB Reconditioned Robots Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure reliability and long-term operational compatibility.

Technical Verification

Confirm that suppliers perform full diagnostic assessments using ABB-certified software tools. Essential procedures include servo motor calibration, gearbox wear analysis, controller firmware restoration, and arc flash safety checks. Request detailed inspection reports showing before-and-after performance metrics such as repeatability accuracy (±0.05mm standard), cycle time consistency, and joint backlash measurements.

Refurbishment Standards

Evaluate the depth of reconditioning processes:

- Complete disassembly, cleaning, and visual/tactile inspection of all structural components

- Replacement of worn consumables (seals, bearings, cables, brakes)

- Functional testing under load conditions simulating real-world applications

- Compliance with ISO 9001 quality management systems for consistent output

Certifications such as CE marking indicate adherence to European health, safety, and environmental standards—critical for cross-border deployment.

Transaction & Support Assurance

Prioritize suppliers offering warranty coverage (minimum 3–6 months) and remote troubleshooting support. Analyze response times (≤7 hours is acceptable; ≤2 hours preferred) and reorder rates as proxies for customer satisfaction. High reorder activity suggests confidence in product reliability and after-sales responsiveness. Consider platforms with verified transaction histories to mitigate counterparty risk during initial engagements.

What Are the Best ABB Reconditioned Robots Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Verified Supplier Type |

|---|---|---|---|---|---|---|---|

| Guangzhou Inbot Technology Ltd. | Commercial Reception, Delivery, Security, Cleaning, Disinfection Robots | 66% | ≤2h | <15% | US $140,000+ | Color, material, size, logo, packaging, label, graphic | Multispecialty Supplier |

| Xiangjing (Shanghai) Mechanical And Electrical Tech Co., Ltd. | IRB4600, IRB6700, IRB14000 Series Robot Arms | 100% | ≤7h | 20% | US $50,000+ | Color, material, size, logo, packaging, label, graphic | Multispecialty Supplier |

| Shandong Chenxuan Robot Technology Co., Ltd. | Painting, Handling, Spray, IRB2600/6700 Arms | 100% | ≤2h | - | - | Color, material, size, logo, packaging, label, graphic | Custom Manufacturer |

| Ae Robotics Co., Ltd. | IRB460, IRB1600, IRB120, IRB2600 Automation Units | 100% | ≤4h | 20% | US $40,000+ | Color, material, size, logo, packaging, label, graphic | Multispecialty Supplier |

| Robotphoenix Intelligent Technology Co.,Ltd | Scara, AGV, Parallel, Material Handling Robots | 100% | ≤2h | 100% | US $30,000+ | Not specified | Not specified |

Performance Analysis

Xiangjing (Shanghai), Shandong Chenxuan, Ae Robotics, and Robotphoenix demonstrate perfect on-time delivery records—a strong indicator of logistical discipline. Robotphoenix stands out with a 100% reorder rate, suggesting exceptional post-purchase satisfaction, likely driven by its niche focus on material handling automation. Guangzhou Inbot, despite high online revenue, shows lower delivery performance (66%) and minimal repeat business, indicating potential inconsistencies in fulfillment or quality alignment.

Suppliers based in Shanghai and Shandong exhibit superior technical specialization in ABB arm models (e.g., IRB4600, IRB6700), offering transparent pricing between $3,500 and $52,000 depending on model and condition. Customization options across most vendors include aesthetic and branding modifications, though functional adaptations require direct engineering consultation. Buyers seeking mission-critical replacements should prioritize partners with documented test protocols and verifiable component traceability.

FAQs

How to verify ABB reconditioned robot supplier reliability?

Review diagnostic documentation, request sample unit inspections, and validate repair methodologies. Cross-reference company credentials against industry registries and assess historical transaction data for dispute frequency. Video audits of workshop environments help confirm compliance with systematic refurbishment workflows.

What is the typical lead time for reconditioned ABB robots?

Standard units are typically available within 15–30 days after order confirmation. Lead times may extend if specific models require sourcing or extensive rebuilding. Expedited processing may be available for urgent deployments at additional cost.

Do suppliers offer warranties on reconditioned units?

Most reputable suppliers provide limited warranties ranging from 3 to 6 months, covering critical subsystems such as drives, controllers, and reducers. Extended coverage may be negotiable based on volume or integration complexity.

Can ABB reconditioned robots be customized for specific applications?

Yes, many suppliers support application-specific adjustments including end-effector interfacing, safety cabling revisions, and HMI language localization. Full customization requires collaboration with technical teams to ensure compatibility with existing production cells.

Are spare parts included with reconditioned robot purchases?

Inclusion varies by supplier. Some bundle common wear items (e.g., brake packs, cable sets), while others offer them as optional add-ons. Clarify spare part availability and inventory support prior to purchase to minimize future downtime.