Abb Smart Robotics

CN

CN

Top sponsor listing

Top sponsor listing

1/5

1/5

1/5

1/5

CN

CN

1/14

1/14

About abb smart robotics

Where to Find ABB Smart Robotics Suppliers?

China's industrial automation sector has emerged as a global hub for robotics integration, with key supplier clusters in Guangdong, Shanghai, and Fujian provinces. These regions host specialized manufacturers offering ABB-compatible smart robotics systems, leveraging mature supply chains for servo components, control modules, and AGV (Automated Guided Vehicle) platforms. Guangzhou and Shanghai serve as primary innovation centers, combining R&D capabilities with high-precision assembly facilities.

Suppliers in these zones benefit from proximity to Tier-1 component vendors and logistics gateways like the Port of Shanghai and Shenzhen Yantian, enabling efficient export operations. The ecosystem supports both turnkey robotic solutions and modular subsystems, with vertical integration reducing lead times by 20–35% compared to non-specialized producers. Buyers gain access to scalable production networks capable of fulfilling orders ranging from single-unit prototypes to multi-system deployments within 45–60 days for standard configurations.

How to Choose ABB Smart Robotics Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

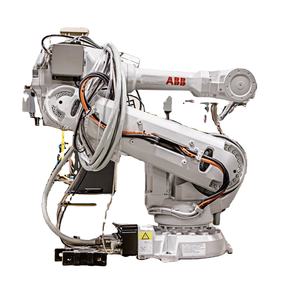

Technical Compatibility & System Integration

Verify that suppliers offer documented compatibility with ABB robot models (e.g., IRB series) and provide interface specifications for PLCs, HMI systems, and fieldbus protocols (PROFINET, EtherCAT). For AGVs and collaborative robots, confirm navigation algorithms (SLAM, magnetic tape guidance), payload accuracy, and safety certification compliance (e.g., ISO 10218, IEC 61508).

Production and Customization Capability

Assess supplier infrastructure through the following criteria:

- In-house engineering teams capable of modifying end-effectors, control logic, or communication interfaces

- Customization options including color, material selection, labeling, and software parameter tuning

- Facility size and output capacity aligned with order volume

Cross-reference on-time delivery performance (target ≥96%) and response time (ideally ≤3 hours) to gauge operational responsiveness.

Quality Assurance and Transaction Security

Prioritize suppliers with verifiable quality management systems. While formal ISO 9001 certification is not universally declared in available data, consistent on-time delivery (100% reported by multiple suppliers) indicates process discipline. Use secure payment mechanisms such as escrow services and request product validation via video inspection or third-party testing. Sample testing should include cycle accuracy, path repeatability, and fail-safe behavior under simulated load conditions.

What Are the Best ABB Smart Robotics Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization |

|---|---|---|---|---|---|---|

| Robotphoenix Intelligent Technology Co.,Ltd | Manipulator, AGV, Parallel Robots, Material Handling Equipment | 100% | 100% | ≤3h | US $30,000+ | Limited |

| Xiangjing (Shanghai) Mechanical And Electrical Tech Co., Ltd. | Industrial Robot Arms (IRB Series), Palletizing Systems | 100% | 20% | ≤7h | US $50,000+ | Yes |

| Anhui Jinhey Tech. Co., Ltd. | Spare Parts, Servo Motors, Articulated Robots, Sensors | 96% | 55% | ≤2h | US $190,000+ | Limited |

| Guangzhou Inbot Technology Ltd. | Commercial Reception, Delivery, Cleaning, Disinfection Robots | 66% | <15% | ≤2h | US $140,000+ | Yes |

| Quanzhou Wetrust Imp. And Exp. Trading Co., Ltd. | ABB Polishing/Grinding Machines, Surface Finishing Systems | 100% | <15% | ≤6h | US $1,000+ | Limited |

Performance Analysis

Robotphoenix stands out with a 100% reorder rate and perfect delivery record, indicating strong customer satisfaction for AGV and material handling systems. Anhui Jinhey demonstrates robust aftermarket support, reflected in its 55% reorder rate and extensive spare parts inventory for ABB-compatible components. Xiangjing (Shanghai) offers direct integration with ABB’s IRB platform, supporting customization while maintaining high delivery reliability. Guangzhou Inbot, despite higher revenue volume, shows lower retention (<15% reorder rate) and delivery performance (66%), suggesting potential scalability or quality consistency challenges. Quanzhou Wetrust focuses on high-value polishing cells ($80,000–$120,000/set), but limited online transaction history warrants due diligence before large-scale procurement.

FAQs

What is the typical MOQ for ABB-integrated robotic systems?

Most suppliers set a minimum order quantity of 1 set/unit for complete robotic systems or major subassemblies. Spare parts may allow smaller quantities depending on availability.

How long are lead times for customized ABB robotic solutions?

Standard units ship within 30–45 days. Custom configurations involving mechanical modifications, software tuning, or special sensors typically require 50–70 days, including testing and factory acceptance.

Do suppliers offer technical documentation and integration support?

Reputable suppliers provide system manuals, wiring diagrams, and basic API/SDK access for control integration. Advanced support (on-site commissioning, remote diagnostics) may incur additional fees and should be confirmed pre-contract.

Are ABB smart robotics suppliers capable of global shipping?

Yes, all listed suppliers have international transaction experience. Confirm Incoterms (FOB, CIF), packaging standards (IP-rated crates), and compliance with destination electrical and safety codes prior to shipment.

Can buyers request product samples or pre-shipment inspections?

Samples are generally available at full cost, with pricing aligned to production expenses. Third-party inspection services (e.g., SGS, BV) are supported upon request and recommended for first-time engagements or high-value orders.