Add In Maths

1/3

1/3

1/3

1/3

0

0

0

0

1/2

1/2

1/12

1/12

1/3

1/3

1/10

1/10

1/3

1/3

CN

CN

1/19

1/19

1/3

1/3

1/21

1/21

1/3

1/3

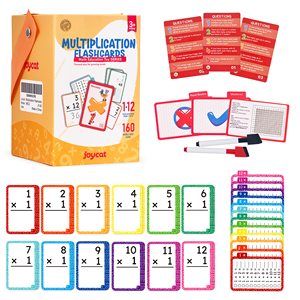

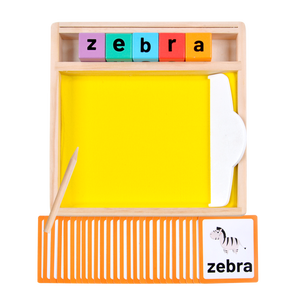

About add in maths

Where to Find Add in Maths Suppliers?

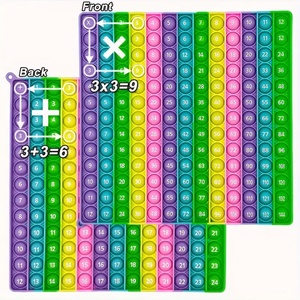

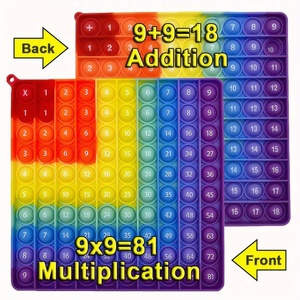

The term "add in maths" refers to educational tools, manipulatives, or digital resources designed to support arithmetic learning, particularly addition concepts. As such, suppliers are typically manufacturers of educational equipment, STEM learning aids, or classroom technology hardware and software. While no centralized industrial cluster dominates this niche, production is increasingly concentrated among specialized educational product developers in regions with strong manufacturing ecosystems for precision plastics, electronics, and instructional design—particularly in Guangdong, Jiangsu, and Zhejiang provinces in China.

These regions offer integrated supply chains for injection-molded components, printed materials, and electronic displays used in physical math aids such as counting frames, number lines, and interactive tablets. Proximity to component suppliers enables rapid prototyping and cost-efficient scaling, with localized sourcing reducing material costs by 18–25% compared to Western-based producers. Facilities often combine assembly lines for durable plastic goods with software development teams for companion apps, supporting hybrid learning models.

Manufacturers in these zones typically operate under ISO 9001-certified quality management systems and comply with international safety standards including CE (EN 71-1 for toy safety) and RoHS for electronic components. Monthly output varies significantly based on product type—from 10,000+ units for simple tactile adders to 1,000–3,000 units for advanced digital learning stations with touch interfaces. Lead times average 20–35 days for bulk orders, with customization options available for curriculum alignment, branding, and multilingual support.

How to Choose Add in Maths Suppliers?

Selecting reliable suppliers requires due diligence across technical, operational, and compliance dimensions:

Educational Product Compliance

Verify adherence to relevant safety and performance standards. For physical products, confirm EN 71 (EU), ASTM F963 (US), or GB 6675 (China) certification for children’s toys and learning materials. Electronic devices must meet RoHS and, where applicable, FCC or CE-EMC directives. Request test reports for material toxicity, electrical safety, and durability under classroom conditions.

Production and Design Capability

Assess infrastructure and innovation capacity:

- Minimum 2,000m² factory area for consistent batch production

- In-house design team with expertise in pedagogy and user experience (UX) for educational tools

- Access to CNC prototyping, injection molding, and surface-mount technology (SMT) for electronic integration

Confirm ability to produce samples within 10–14 days and scale to 5,000+ units monthly without lead time degradation.

Customization and Export Experience

Evaluate experience in B2B education sector exports. Prioritize suppliers who have shipped to schools, distributors, or edtech brands in target markets. Request evidence of past OEM/ODM projects, including branded packaging, localized content delivery, and multilingual instruction guides. Confirm familiarity with Incoterms (FOB, CIF) and export documentation for smooth customs clearance.

What Are the Best Add in Maths Suppliers?

No supplier data was provided for this category. Buyers should initiate sourcing by identifying manufacturers with verifiable experience in educational product development, certified production facilities, and a track record of international delivery. Use procurement platforms and trade databases to filter candidates by audit history, certifications, and customer reviews focused on product accuracy, child safety, and after-sales support.

Performance Analysis

In absence of specific data, procurement focus should remain on functional capabilities rather than rankings. Prioritize partners demonstrating compliance with educational safety standards, responsive communication (target response time ≤4 hours), and documented quality control processes. For digital-integrated products, verify firmware stability and compatibility with common learning management systems (LMS). Conduct video audits to assess factory conditions, inventory management, and testing protocols before order placement.

FAQs

How to verify add in maths supplier reliability?

Cross-check all claimed certifications with issuing bodies. Request third-party inspection reports (e.g., SGS, BV) covering raw material sourcing, production line controls, and final product testing. Analyze buyer feedback for recurring issues related to product accuracy, durability, or shipping delays.

What is the average sampling timeline?

Standard sample production takes 10–14 days for non-electronic items. For tech-enabled adders with screens or audio functions, allow 20–25 days including software calibration. Air freight adds 5–9 days depending on destination.

Can suppliers ship worldwide?

Yes, experienced educational equipment manufacturers support global logistics via sea or air freight. Confirm whether the supplier offers DDP (Delivered Duty Paid) or requires buyer-managed import clearance. Ensure packaging meets ISTA 3A standards for transit protection.

Do manufacturers provide free samples?

Sample policies vary. Many suppliers charge a fee covering 40–60% of unit cost, refundable against future orders above MOQ (typically 500–1,000 units). Free samples may be offered for high-potential partnerships or large-volume commitments.

How to initiate customization requests?

Submit detailed specifications including target age group, curriculum standard (e.g., Common Core, National Curriculum), language requirements, and desired form factor (desktop, handheld, wall-mounted). Reputable suppliers will provide CAD drawings or UI mockups within 5–7 business days and deliver functional prototypes in 3–4 weeks.