Additive Manufacturing Examples

About additive manufacturing examples

Where to Find Additive Manufacturing Examples Suppliers?

China remains a central hub for additive manufacturing (AM) service providers, with key clusters in Guangdong and Shanghai offering specialized capabilities in rapid prototyping, low-volume production, and industrial 3D printing. Guangdong-based suppliers leverage proximity to high-tech manufacturing zones and advanced material supply chains, enabling efficient processing of polymers, metals, and composites. Shanghai’s ecosystem emphasizes engineering-driven customization, particularly in metal AM and functional prototypes for automotive and aerospace sectors.

These regions host vertically integrated facilities combining design, scanning, simulation, and post-processing under one roof. This integration reduces lead times by up to 40% compared to fragmented outsourcing models. Buyers benefit from access to multi-technology platforms—including SLS, SLA, FDM, and SLM—alongside localized logistics networks that support global shipping. Typical advantages include MOQs as low as 1 unit, per-part pricing starting below $0.20, and turnaround times averaging 5–10 days for standard orders.

How to Choose Additive Manufacturing Examples Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technology & Material Capabilities

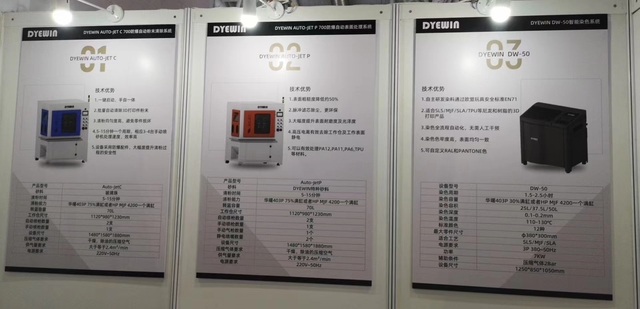

Confirm availability of required AM processes: Selective Laser Sintering (SLS), Stereolithography (SLA), Fused Deposition Modeling (FDM), or Metal Laser Powder Bed Fusion (SLM). Verify supported materials—such as PA12, TPU, stainless steel, titanium alloy, and resin—and compatibility with end-use requirements. Suppliers offering electroplating, painting, bonding, or chrome plating indicate advanced post-processing infrastructure.

Quality Assurance and Compliance

While explicit ISO or CE certifications are not disclosed in available data, prioritize suppliers demonstrating consistent on-time delivery (target: 100%) and verifiable reorder rates (>35%). Request documentation of internal quality control protocols, including dimensional accuracy checks, surface finish standards, and file format compatibility (STL, 3MF, etc.). For regulated industries, confirm adherence to sector-specific testing benchmarks.

Customization and Design Support

Evaluate suppliers based on design flexibility and digital workflow integration. Key indicators include STL file acceptance, CAD/CAM support, logo embedding, color options, and packaging customization. Rapid response times (≤5 hours) correlate with higher service responsiveness and iterative design capability.

Transaction Reliability

Assess online revenue performance as a proxy for market validation—suppliers reporting US$60,000+ annual online sales demonstrate sustained buyer engagement. Cross-reference product listings with minimum order clarity and transparent pricing structures. Use secure payment terms and request sample parts to validate print quality before scaling procurement.

What Are the Best Additive Manufacturing Examples Suppliers?

| Company Name | Location | Main Products | Price Range (Min–Max) | MOQ | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shanghai Yunyan Prototype And Mould Manufacture Factory | Shanghai, CN | Metal AM, Rapid Prototyping, Resin Printing | $0.20–$1.00 | 1 piece | 100.0% | ≤3h | US $60,000+ | 38% |

| Tai'an Guangyuan International Trade Co., Ltd. | Shandong, CN | Industrial Additives, Petrochemical Compounds | $0.90–$800 | 1 kg – 20 MT | 100.0% | ≤3h | US $250,000+ | 36% |

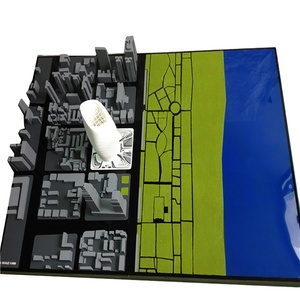

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Guangdong, CN | SLS/SLA, Construction Printing, Toy Models | $0.69–$9.90 | 1 unit | 100.0% | ≤5h | US $30,000+ | 85% |

| HUITONG RAPID PROTOTYPE & SUPPLY COMPANY LIMITED | Guangdong, CN | Metal SLM, Precision Components, Jewelry | $0.50–$13.90 | 1 piece | 100.0% | ≤4h | US $30,000+ | 25% |

| Pulesheng Technology (Guangdong) Co., Ltd. | Guangdong, CN | FDM, Stainless Steel 3D Printing, Powder Bed Fusion | $0.90–$2.50 | 2–50 pieces | 100.0% | ≤10h | US $100+ | - |

Performance Analysis

Guangzhou Gaojie stands out with an 85% reorder rate—the highest among listed suppliers—indicating strong customer satisfaction in model design and niche applications like construction-scale printing. Shanghai Yunyan offers competitive per-unit pricing ($0.20) for metal and resin parts, backed by sub-3-hour response times and broad customization options. Tai’an Guangyuan targets bulk chemical additive needs rather than physical part production, serving distinct industrial segments. HUITONG excels in high-value metal components with thermal conductivity and die-steel applications, while Pulesheng provides cost-effective FDM and powder-bed solutions at scale. All top-tier suppliers maintain 100% on-time delivery, underscoring operational reliability despite varying levels of public transaction history.

FAQs

How to verify additive manufacturing supplier reliability?

Evaluate consistency in delivery performance (target: 100%), response speed (ideally ≤5h), and reorder metrics (above 35% preferred). Request sample prints to assess dimensional accuracy, surface finish, and material properties. Validate technical capabilities through direct inquiries about build volume, layer resolution, and post-processing methods.

What is the typical lead time for additive manufacturing orders?

Standard orders are typically fulfilled within 5–10 business days. Rapid prototyping requests may be completed in 3–5 days, depending on complexity and finishing requirements. Bulk or chemically processed orders (e.g., petrochemical additives) may require longer scheduling due to regulatory handling protocols.

Can suppliers handle both plastic and metal 3D printing?

Yes, leading suppliers such as Shanghai Yunyan and HUITONG offer dual-material capabilities, including nylon, TPU, stainless steel, aluminum, and titanium via SLS and SLM technologies. Confirm machine capacity and support for specific alloys or engineering-grade polymers prior to order placement.

Do suppliers accept small-batch or single-unit orders?

Most suppliers accommodate MOQs of 1–2 units, especially for prototype development and customized designs. This enables cost-efficient testing and iteration without large upfront commitments. Pricing transparency across unit quantities supports scalable procurement planning.

How to initiate a customization request for 3D-printed parts?

Submit detailed specifications including 3D model files (STL, STEP), material preference, tolerances, surface treatment, color, and functional requirements. Reputable suppliers will provide design feedback, quotation, and estimated delivery within 24–72 hours.