Formative Manufacturing Examples

Top sponsor listing

Top sponsor listing

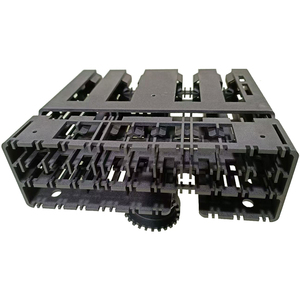

About formative manufacturing examples

Where to Find Formative Manufacturing Service Providers?

China remains a central hub for formative manufacturing services, with specialized precision engineering clusters concentrated in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated facilities combining CNC machining, additive manufacturing, rapid prototyping, and low-volume production under one ecosystem. Dongguan and Guangzhou in Guangdong province lead in high-precision metal and plastic component fabrication, leveraging proximity to material suppliers and export ports to reduce logistics lead times by up to 30%. Suzhou and Hangzhou serve as technology-forward centers, hosting suppliers with advanced 5-axis milling, SLS/SLA 3D printing, and metrology capabilities such as CMM inspection and dimensional accuracy validation.

The industrial maturity of these zones enables scalable production responses, with many suppliers operating automated lines capable of fulfilling orders from single-unit prototypes to batch runs exceeding 10,000 units. Integrated supply networks allow for same-week material sourcing and in-house post-processing—including heat treatment, electroplating, and custom packaging—reducing dependency on external vendors. Buyers benefit from competitive pricing (unit costs ranging $0.01–$2.99), fast turnaround (typical lead times of 7–15 days for prototypes), and strong customization flexibility across materials like aluminum, stainless steel, titanium, POM, and photosensitive resins.

How to Choose Formative Manufacturing Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional criteria:

Technical & Processing Capabilities

Verify access to multi-axis CNC machining (4-axis and 5-axis preferred), selective laser sintering (SLS), stereolithography (SLA), and vacuum casting. Suppliers should demonstrate proficiency in tight-tolerance work (±0.005 mm achievable) and offer surface finish options including sandblasting, mirror polishing, and dark chrome coating. Confirm compatibility with engineering-grade materials such as PEBA, TPEE, cobalt-chromium, and die steel.

Quality Assurance & Compliance

While formal ISO 9001 certification is not explicitly stated in available data, prioritize suppliers with documented quality control processes such as CMM inspection, first-article testing, and drawing validation. Look for evidence of traceable production workflows, including digital file creation, 3D scanning, and approval cycles for design outputs. Reorder rates above 50% and on-time delivery performance exceeding 97% indicate consistent service execution.

Customization & Design Support

Leading providers support full product lifecycle services—from concept modeling to mass production—with customization covering:

- Material selection (metal, plastic, resin)

- Color matching (Pantone standards supported)

- Logo, label, and graphic application

- Precision tolerance control

- Low-volume tooling and mold development

- Software-compatible 3D file generation (STL, STEP formats)

Response times under 5 hours and online revenue exceeding US $100,000 signal active operations and customer engagement capacity.

What Are the Top Formative Manufacturing Service Providers?

| Company Name | Main Services | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Key Capabilities |

|---|---|---|---|---|---|---|

| Suzhou Konlida Precision Electronic Co., Ltd. | Machining, Insulation & RF Shielding | 100% | 22% | ≤3h | US $430,000+ | High-volume machining; material diversity; packaging customization |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Additive Manufacturing, Prototyping | 100% | 80% | ≤5h | US $20,000+ | SLS/SLA 3D printing; mockup development; sample production from $0.15/unit |

| Dongguan Formal Precision Metal Parts Co., Ltd. | CNC Machining, 4-Axis Milling | 87% | 29% | ≤5h | US $110,000+ | Aluminum, stainless steel, titanium parts; tight tolerances; forging and heat transfer options |

| Hangzhou Aoyi Trade Co., Ltd. | 5-Axis CNC, Rapid Prototyping | 97% | 53% | ≤3h | US $170,000+ | Multi-material processing; DLP/DLS printing; swappable battery integration; full-color printing |

| Huzhou Dear Industry Co., Ltd. | OEM Machining, 3D Printing | 100% | 50% | ≤6h | US $370,000+ | Injection molding support; EPDM/TPU materials; transparent part fabrication; scalable batch production |

Performance Analysis

Guangzhou Gaojie stands out with an 80% reorder rate, indicating high client retention driven by responsive service and cost-effective prototyping solutions starting at $0.15 per unit. Hangzhou Aoyi combines advanced 5-axis CNC and polyjet printing with comprehensive finishing options, achieving near-perfect on-time delivery (97%) and strong mid-tier reorder performance. Huzhou Dear Industry demonstrates scalability with the second-highest online revenue and broad material customization, suitable for long-term OEM partnerships. Suzhou Konlida leads in volume output across non-mechanical components like RF shielding and insulation elements, though its lower reorder rate suggests room for improvement in customer engagement. Dongguan Formal offers robust metal machining but lags slightly in delivery consistency compared to peers.

FAQs

What are common formative manufacturing techniques offered?

Suppliers typically provide CNC turning/milling (3-axis to 5-axis), SLS, SLA, DLP, and vacuum casting. Some integrate hybrid approaches, combining additive methods with secondary machining for complex geometries and functional prototypes.

What is the typical minimum order quantity (MOQ)?

Most suppliers list MOQs of 1–2 pieces for prototypes and samples, enabling low-risk design validation. For injection molding or tooling-dependent processes, MOQs may start at 100 units depending on complexity.

How long does it take to receive a prototype?

Standard lead time ranges from 7 to 12 days after design approval. Expedited services may reduce this to 5 days, especially for 3D-printed or CNC-machined parts without tooling requirements.

Do suppliers support international shipping and compliance?

Yes, all listed suppliers have established export operations. Buyers must confirm adherence to destination-market standards for material safety (e.g., RoHS, REACH) and electrical compliance where applicable. Documentation support varies—request test reports and material certifications upfront.

Can I request design modifications during production?

Design revisions are generally accommodated during prototyping stages. However, changes post-tooling incur additional costs and delays. Clear communication via technical drawings, STL files, and annotation tools minimizes iteration cycles.