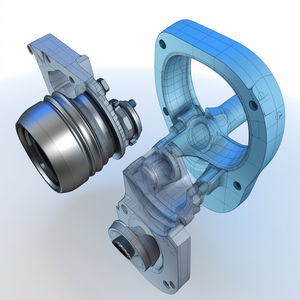

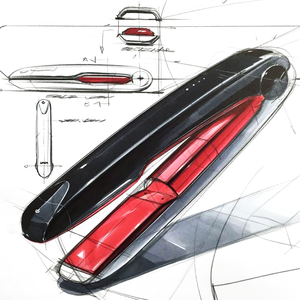

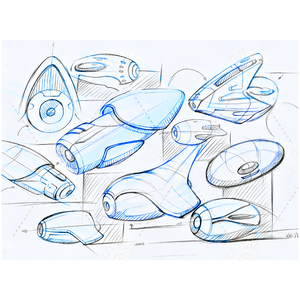

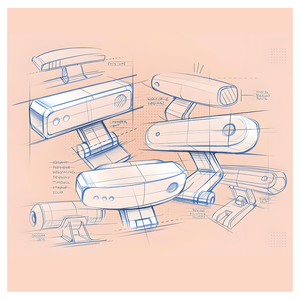

Design For Manufacturing Examples

Top sponsor listing

Top sponsor listing

1/31

1/31

1/21

1/21

1/17

1/17

1/10

1/10

1/18

1/18

1/12

1/12

1/8

1/8

1/46

1/46

About design for manufacturing examples

Where to Find Design for Manufacturing Suppliers?

China remains a central hub for design for manufacturing (DFM) services, with specialized suppliers concentrated in Guangdong Province—particularly in Dongguan, Shenzhen, and Huizhou. These regions host vertically integrated industrial ecosystems that combine advanced prototyping, precision machining, and rapid tooling capabilities. The proximity to material suppliers, electronics manufacturers, and logistics networks enables streamlined DFM workflows, reducing time-to-market by up to 40% compared to decentralized sourcing models.

Suppliers in this cluster offer end-to-end product development support, from initial concept modeling to full-scale production. Facilities typically integrate CAD/CAM software with CNC machining, 3D printing, sheet metal fabrication, and injection molding, allowing seamless transition from design to manufacturability analysis. Buyers benefit from localized supply chains that reduce component lead times and enable agile iteration during the prototyping phase. Average production cost savings range from 20–35% due to optimized labor efficiency and in-house process control.

How to Choose Design for Manufacturing Suppliers?

Selecting a reliable DFM partner requires structured evaluation across technical, operational, and transactional dimensions:

Design & Engineering Capabilities

Verify access to multi-disciplinary engineering expertise, including mechanical design, electronic integration (PCB, firmware), and industrial design (ID). Preferred suppliers maintain dedicated R&D teams capable of delivering 3D renderings, structural simulations, and design validation reports within 72 hours of inquiry. Cross-check software proficiency in SolidWorks, AutoCAD, STP, and STL formats.

Manufacturing Integration

Assess whether the supplier operates in-house production lines for key processes:

- Sheet metal fabrication, CNC turning/milling, or plastic injection molding

- Prototyping methods such as vacuum casting, 3D printing (PLA, resin, metal)

- Custom packaging, labeling, and assembly services

Integrated facilities minimize outsourcing risks and ensure tighter tolerances, with typical accuracy reaching ±0.01mm for machined components.

Quality Assurance & Transaction Metrics

Prioritize suppliers demonstrating consistent performance indicators:

- On-time delivery rate ≥90%

- Reorder rate >30%, indicating client retention

- Response time under 4 hours

While formal certifications like ISO 9001 are not universally listed, verify internal QC protocols covering material sourcing, die-cast specifications, and final product testing (e.g., TPU elasticity checks, nylon durability).

What Are the Best Design for Manufacturing Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Topwell Innovations Co., Ltd. | Moulds, Machining Services, Electronic Design | Biodegradable materials, PCB design, firmware, 3D rendering, vacuum casting, ID & packaging | 100% | 50% | ≤4h | US $710,000+ | 1 set | $100–500 |

| Dongguan Hejia Electronic Technology Co., Ltd. | Moulds, Sheet Metal Fabrication, Machining | ABS modeling, 3D drawing, industrial design | 84% | 34% | ≤3h | US $240,000+ | 1 piece | $10 |

| Huizhou Jiyan Hardware Co., Ltd. | Shafts, Casting, Sheet Metal, Moulds | Material size, logo, packaging, graphic dimensions | 100% | 15% | ≤2h | US $40,000+ | Not specified | Not listed |

| Dongguan Kewei Hardware Electronics Co., Ltd. | Moulds, Machining Services | 2D/3D drawing, CAD scanning, STP modeling | 100% | 100% | ≤4h | US $6,000+ | 1 piece | $0.80–2.00 |

| Yuyao Taike Mold Factory | Machining Services, Moulds | 3D printing, stainless steel prototypes | 72% | 33% | ≤6h | US $30,000+ | 1 acre | $2.40–4.60 |

Performance Analysis

Shenzhen Topwell stands out for comprehensive DFM integration, offering full-spectrum services from electronic design to mold creation and final assembly, supported by a high reorder rate and extensive customization scope. Dongguan Kewei demonstrates exceptional customer loyalty with a 100% reorder rate, though its lower online revenue suggests niche specialization. Huizhou Jiyan and Dongguan Kewei both achieve perfect on-time delivery records with sub-4-hour response times, making them suitable for urgent design requests.

Yuyao Taike, while active in 3D printing and prototype development, shows a relatively lower on-time delivery rate (72%), indicating potential bottlenecks in order fulfillment. Pricing varies significantly—from $0.80 for basic CAD modeling to $500 for complete industrial design packages—allowing flexibility based on project scale and complexity. Suppliers with higher online revenues (e.g., Hejia, Topwell) likely manage larger client volumes and more complex projects.

FAQs

How to verify design for manufacturing supplier reliability?

Evaluate response consistency, on-time delivery history, and breadth of customization options. Request sample design packages or 3D renderings to assess technical accuracy. Confirm alignment between stated capabilities (e.g., PCB design, vacuum casting) and actual service offerings through direct communication.

What is the typical lead time for DFM services?

Initial design drafts are typically delivered within 3–5 business days. Prototyping takes 7–14 days depending on complexity and method (e.g., 3D printing vs. CNC machining). Full production timelines vary based on MOQ and manufacturing process integration.

Do suppliers support low-volume or one-off design orders?

Yes, most suppliers accept minimum orders of 1 piece or set, particularly for design and prototyping services. This supports startups and R&D departments requiring iterative development without upfront volume commitments.

Can DFM suppliers handle electronic and mechanical integration?

Top-tier providers like Shenzhen Topwell offer combined mechanical, electronic, and firmware design, enabling fully functional product development. Confirm capability in PCB layout, component sourcing, and embedded system design before engagement.

How are design files protected during collaboration?

Buyers should establish NDAs prior to sharing sensitive IP. Reputable suppliers implement secure file transfer protocols and restrict access to authorized engineers. Verify data protection practices during initial inquiries.