Example Of Manufacturing

Top sponsor listing

Top sponsor listing

1/8

1/8

CN

CN

1/24

1/24

1/35

1/35

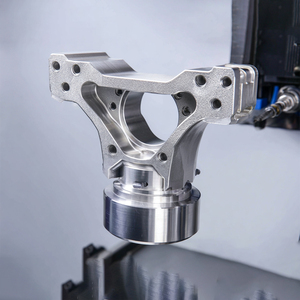

About example of manufacturing

Where to Find Manufacturing Services Suppliers?

China remains a global hub for contract manufacturing, with key supplier clusters in Fujian, Guangdong, and Zhejiang provinces offering specialized capabilities in precision machining, sheet metal fabrication, and injection molding. Fuzhou and Ningbo host mature ecosystems for mixed-material production, integrating design, prototyping, and low-to-mid volume assembly under one supply chain. Shenzhen and Dongguan excel in high-precision CNC services, supported by dense networks of material suppliers and metrology labs that reduce component lead times by 20–35% compared to offshore alternatives.

These industrial zones enable rapid iteration through co-located tooling, heat treatment, and surface finishing providers, allowing suppliers to deliver turnkey solutions within tight tolerances (±0.005mm standard). Buyers benefit from scalable capacity, with facilities averaging 3,000–8,000m² and monthly output ranging from 10,000 to 50,000 units depending on complexity. Localization also supports cost efficiency—production expenses are typically 25–40% lower than in North America or Western Europe due to optimized labor and logistics structures.

How to Choose Manufacturing Services Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

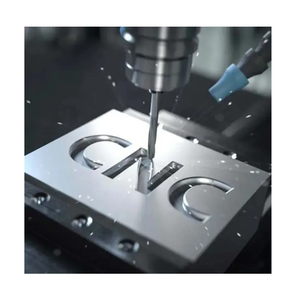

Technical Capability Assessment

Confirm access to multi-axis CNC machining (3-axis to 5-axis), EDM, and Swiss turning for complex geometries. For sheet metal work, verify stamping presses up to 200 tons and laser cutting accuracy within ±0.1mm. Injection molding partners should offer molds in hardened steel (HRC 48–52) with cavity pressure monitoring. Acceptable file formats include STEP, IGES, and 3D PDF for design validation.

Quality Management Verification

While formal ISO 9001 certification is not universally listed, prioritize suppliers demonstrating consistent on-time delivery (>95%) and documented inspection protocols. Look for evidence of first-article inspection (FAI), in-process gauging, and final quality reports using CMM or optical comparators. Surface treatments such as electroless nickel plating, anodizing (Type II/III), and powder coating should follow ASTM or MIL standards where applicable.

Operational Performance Indicators

Evaluate responsiveness (target ≤2 hours), reorder rate (indicative of customer satisfaction), and minimum order quantities (MOQs). Leading suppliers support prototyping at 1-piece MOQ and scale to 100+ units with linear cost progression. Lead times average 15–25 days for initial batches, including tooling setup for custom molds or fixtures.

What Are the Best Manufacturing Services Suppliers?

| Company Name | Main Products | Materials Offered | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue |

|---|---|---|---|---|---|---|---|

| Fuzhou Jiahexing Machinery Co., Ltd. | Machining Services, Moulds, Sheet Metal Fabrication, Aviation Parts | Steel, Aluminum, Plastic, Hardened Steel, STP Format Materials | Material, size, drawings, logo, mold design, packaging, label, color, weight | 100% | 23% | ≤2h | US $110,000+ |

| Shenzhen Ruichenxing Industry Co., Ltd. | Machining Services, Forging Services, Tool Sets | Aluminum, Steel, Anodized Alloys | CNC customization, anodized finishes, OEM configurations | 100% | 32% | ≤1h | US $970,000+ |

| Ningbo Aoling Machinery Manufacturing Co., Ltd. | Machining Services, Casting Services, Sheet Metal Fabrication | Stainless Steel, Aluminum, Brass, Iron, Alloy | Investment casting, milling, turning, OEM processing | 92% | 62% | ≤5h | US $50,000+ |

| Dongguan Zhonglijin Metal Products Co., Ltd. | Casting Services, Machining Services, Sheet Metal Fabrication | Aluminum, Stainless Steel, Other Metals | Precision CNC, material grade selection, dimensional control | 100% | 20% | ≤8h | US $40,000+ |

| JUNYING METAL MANUFACTURING CO., LIMITED | Machining Services | Stainless Steel, Titanium, Magnesium, Zinc, Aluminum Alloy | Medical/aerospace-grade CNC parts, plastic injection, small metal components | 100% | - | ≤2h | - |

Performance Analysis

Shenzhen Ruichenxing stands out with the highest online revenue and a 32% reorder rate, indicating strong market acceptance and repeat business. Despite a lower reported delivery performance, Ningbo Aoling demonstrates exceptional customer retention (62% reorder rate), suggesting high satisfaction with product quality and service consistency. Fuzhou Jiahexing and JUNYING METAL both achieve 100% on-time delivery with rapid response times, making them reliable for time-sensitive procurement. Suppliers in Shenzhen and Fuzhou lead in responsiveness, with average replies within 2 hours, critical for iterative design validation and urgent RFQ cycles.

FAQs

How to verify manufacturing supplier reliability?

Assess performance metrics such as on-time delivery rate, reorder frequency, and response speed. Request process documentation including inspection reports, material certifications, and equipment lists. Conduct virtual audits via facility videos or live calls to confirm in-house capabilities versus subcontracting reliance.

What is the typical MOQ and pricing range?

Most suppliers offer 1-piece MOQ for prototypes and 10–100 pieces for production runs. Unit prices range from $0.25 to $20 depending on material, complexity, and finishing requirements. High-volume orders (1,000+ units) typically yield 15–30% cost reduction through tooling amortization and batch processing.

Can suppliers handle full-cycle production?

Yes, leading providers manage end-to-end processes—from raw material sourcing and CNC machining to surface treatment, assembly, and packaging. Full-service suppliers often support DFM feedback within 24–48 hours of design submission, reducing time-to-market for new products.

Do manufacturers support international shipping?

All listed suppliers engage in cross-border trade, with export experience to North America, Europe, and Asia-Pacific. Confirm Incoterm preferences (FOB, EXW, CIF) and ensure compliance with destination-specific regulatory standards, especially for medical, aerospace, or automotive applications.

How to initiate customization requests?

Submit detailed technical files (STEP, DWG, or PDF) specifying dimensions, tolerances, materials, and surface finish requirements. Clearly define functional needs such as load-bearing capacity, corrosion resistance, or biocompatibility. Reputable suppliers respond with manufacturability analysis and quotation within 24–72 hours.