Example Of Manufacturing Operations

Top sponsor listing

Top sponsor listing

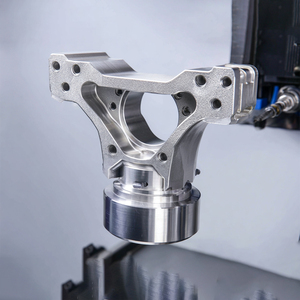

About example of manufacturing operations

Where to Find Manufacturing Operations Suppliers?

China remains a global hub for contract manufacturing, with concentrated industrial clusters in Guangdong and Zhejiang provinces driving efficiency and specialization. Shenzhen and Dongguan in Guangdong province host advanced precision engineering ecosystems, supporting high-mix, low-to-medium volume production runs with rapid prototyping capabilities. These regions benefit from proximity to Tier-1 suppliers of raw materials and electronic components, reducing material lead times by 20–30% compared to offshore alternatives.

Zhejiang’s Ningbo and Hangzhou zones specialize in heavy machining and casting operations, leveraging integrated foundry networks and port access for cost-effective export logistics. The region's mature supply chain infrastructure enables vertically aligned production—from CNC milling and sheet metal fabrication to die-casting and surface treatment—reducing outsourcing dependencies. Buyers can expect typical lead times of 15–30 days for custom machined parts, with scalability for batch sizes ranging from prototypes to tens of thousands of units.

How to Choose Manufacturing Operations Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Process Compliance

Verify adherence to internationally recognized quality standards such as ISO 9001. For clients in regulated industries (e.g., medical, automotive), confirm compliance with IATF 16949 or AS9100 where applicable. Assess documentation practices for material traceability, first-article inspection reports (FAIR), and process capability studies (Cp/Cpk).

Production Capacity Assessment

Evaluate core manufacturing competencies through the following criteria:

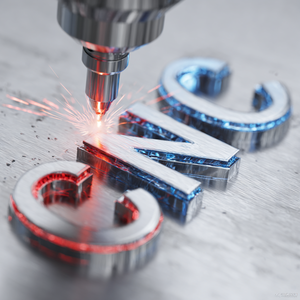

- In-house capabilities covering CNC machining, sheet metal fabrication, plastic/pressure die-casting, and mold making

- Minimum facility size of 2,000m² for scalable production

- Availability of secondary processes: anodizing, plating, laser engraving, packaging customization

- On-time delivery performance exceeding 93%, validated through historical transaction data

Cross-reference supplier claims with response time metrics (target ≤4 hours) and reorder rates as indicators of customer satisfaction and operational reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms tied to milestone deliveries. Prioritize suppliers offering sample validation before mass production. Confirm packaging and labeling compliance for destination-market regulations. Request digital factory audits or video walkthroughs to verify equipment conditions and workflow organization.

What Are the Best Manufacturing Operations Suppliers?

| Company Name | Location | Main Services | Materials Handled | Min. Order Quantity | On-Time Delivery | Avg. Response | Reorder Rate | Annual Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Xie Lifeng Technology Co., Ltd. | Guangdong, CN | Machining, Casting, Molding, Sheet Metal | Aluminum, Steel, Plastic, Brass | Varies by product | 98% | ≤4h | 32% | US $930,000+ |

| Ningbo Aoling Machinery Manufacturing Co., Ltd. | Zhejiang, CN | CNC Machining, Casting, Sheet Metal | Aluminum, Brass, Iron, Stainless Steel | 10–100 pcs | 93% | ≤5h | 62% | US $50,000+ |

| FENG CHENG MACHINERY INDUSTRIAL CO., LTD. | Taiwan, CN | Precision CNC, Forging, Casting | Aluminum, Stainless Steel, Alloy | 100 pcs | 100% | ≤2h | 16% | US $1,000+ |

| Dongguan Senyuan Hardware Co., Ltd. | Guangdong, CN | CNC Machining, Milling, Turning | Aluminum, Stainless Steel, Metal Alloys | 5 pcs | 100% | ≤1h | 27% | US $180,000+ |

| Dongguan Ronghang Hardware Mould Co., Ltd. | Guangdong, CN | OEM Machining, Precision Components | Stainless Steel, Aluminum, Titanium, Brass | 1 pc | 93% | ≤2h | 38% | US $360,000+ |

Performance Analysis

Dongguan-based suppliers demonstrate superior responsiveness, with two vendors achieving sub-2-hour average reply times and 100% on-time delivery. Shenzhen Xie Lifeng stands out for service breadth, offering end-to-end solutions including molds and plastic products. Ningbo Aoling exhibits strong client retention (62% reorder rate), indicating consistent quality execution despite moderate online revenue. Dongguan Ronghang supports ultra-low MOQs starting at one piece, ideal for prototyping and niche applications. FENG CHENG achieves perfect delivery performance but has limited transaction volume, suggesting capacity constraints for large-scale orders.

FAQs

How to verify manufacturing operations supplier reliability?

Validate certifications through official registries and request evidence of internal quality control systems. Analyze supplier response consistency, order fulfillment history, and customer feedback focused on defect rates and communication transparency. Conduct virtual or on-site audits to assess machine maintenance logs and workforce training protocols.

What is the typical lead time for custom manufacturing projects?

Standard CNC machining orders take 10–20 days post-design approval. Complex assemblies involving tooling or casting require 25–40 days. Add 5–10 days for international air freight or 25–40 days for sea shipping depending on destination.

Can suppliers handle full product customization?

Yes, most suppliers support OEM/ODM services including material selection, dimensional adjustments, logo imprinting, color coding, and custom packaging. Technical specifications must be provided in STEP/IGES/DXF formats for quotation and feasibility review.

Do manufacturers offer free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to future bulk orders. Others charge partial production costs recoverable against initial purchase orders. Expect 5–15 days for sample production and 3–7 days for express delivery.

What are common MOQs in precision manufacturing?

MOQs range from 1 piece (prototypes) to 100 pieces for economical unit pricing. High-volume runs typically start at 1,000 units. Negotiation is possible based on material utilization and setup efficiency. Suppliers may adjust MOQs for long-term contracts or recurring orders.