Example Of Manufacturing And Production

CN

CN

CN

CN

About example of manufacturing and production

Where to Find Custom Manufacturing and Production Suppliers?

China remains a central hub for flexible manufacturing and production services, with key supplier clusters in Guangdong and Zhejiang provinces offering specialized capabilities in rapid prototyping, low-volume customization, and full-scale OEM/ODM production. Shenzhen and Dongguan in Guangdong are recognized for advanced electronics integration, CNC machining, and 3D printing ecosystems, supported by dense networks of material suppliers and logistics providers. Yuyao in Zhejiang has emerged as a mold-making center, hosting over 1,200 mold-related enterprises that enable fast tooling development for plastic and metal components.

These industrial zones support vertically integrated workflows—from design and prototyping to mass production—allowing suppliers to deliver customized solutions within compressed timelines. Buyers benefit from localized supply chains that reduce component procurement lead times by up to 40% compared to offshore alternatives. Typical advantages include MOQs as low as 1 piece, lead times of 7–15 days for prototypes, and scalability for orders exceeding 10,000 units. Regional specialization enables precise alignment between buyer requirements and supplier expertise, whether for industrial equipment, consumer electronics, or novelty products.

How to Choose Manufacturing and Production Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Customization Capability Assessment

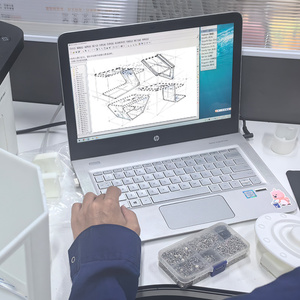

Confirm support for drawing-based and sample-based customization, which ensures accurate replication of complex geometries and functional specifications. Suppliers should offer multiple processing methods including CNC machining, injection molding, SLA/FDM 3D printing, and surface treatments such as anodization or silk screening. Evaluate flexibility in material selection—common options include aluminum, PVC, rubber, and impact-resistant polymers—and verify compatibility with end-use environmental conditions.

Production Infrastructure Verification

Assess core manufacturing assets through the following criteria:

- In-house production lines with documented capacity (e.g., machining centers, molding machines)

- Demonstrated ability to handle both small-batch customization and scalable output

- Technical team proficiency in CAD/CAM software and prototype validation

Cross-reference self-reported capabilities with on-time delivery performance; suppliers maintaining ≥82% on-time fulfillment are more likely to meet committed deadlines under variable order volumes.

Quality and Transaction Reliability

While formal certifications (e.g., ISO 9001) are not universally listed, consistent on-time delivery rates above 80% and response times under 5 hours indicate operational discipline. Prioritize suppliers with transparent communication channels and documented quality control checkpoints. For high-value or regulated products, request material test reports, process flowcharts, and inspection protocols before scaling orders.

What Are the Leading Manufacturing and Production Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Kaier Wo Prototyping Technology Co., Ltd. | Guangdong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤2h | US $940,000+ | 40% |

| Maxsen Intelligent Equipment (Dongtai) Co., Ltd. | Jiangsu, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤5h | US $3,000+ | <15% |

| Shenzhen Yideyi Technology Co., Ltd. | Guangdong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤5h | US $60,000+ | <15% |

| Yuyao Taike Mold Factory | Zhejiang, CN | Data Unavailable | Data Unavailable | Data Unavailable | 73.0% | ≤6h | US $20,000+ | 33% |

| Dongguan Wanlai Wanqu Toys Co., Ltd. | Guangdong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 82.0% | ≤5h | US $5,000+ | <15% |

Performance Analysis

Shenzhen Kaier Wo stands out with the highest reported online revenue and a 40% reorder rate, indicating strong customer satisfaction in rapid prototyping and 3D printing services. Maxsen Intelligent Equipment and Shenzhen Yideyi demonstrate full reliability in on-time delivery, making them suitable for time-sensitive industrial projects. Yuyao Taike Mold Factory offers extensive machining and mold-making listings but lags in delivery consistency (73%), suggesting potential bottlenecks during peak demand. Dongguan Wanlai Wanqu serves niche markets like novelty toys with very low MOQs (1 piece) and competitive pricing, though its lower reorder rate indicates limited repeat engagement. Buyers requiring precision engineering should prioritize suppliers with proven responsiveness and documented customization workflows.

FAQs

How to verify manufacturing supplier reliability?

Evaluate on-time delivery records, response speed, and transaction volume as proxies for operational stability. Request facility photos or video tours to confirm in-house production capabilities. For critical applications, conduct third-party inspections prior to shipment and validate material compliance through sample testing.

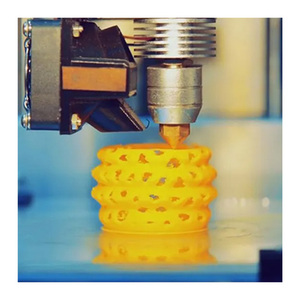

What is the typical sampling timeline?

Prototype lead times range from 5 to 12 days depending on complexity. 3D-printed samples are typically delivered within one week, while molded parts may require additional tooling time (7–14 days). Shipping via express carriers adds 3–7 days for international delivery.

Can suppliers handle global shipping?

Yes, most suppliers support international logistics via air freight, sea freight, or courier services. Confirm Incoterms (e.g., FOB, CIF) during negotiation and ensure packaging meets destination country standards, especially for fragile or electronic components.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers offer paid samples with fees redeemable against future orders. Free samples are occasionally provided for high-potential buyers or standardized items. Expect unit costs between $0.50 and $10 for 3D-printed or machined prototypes.

How to initiate customization requests?

Submit detailed technical drawings, STL files, or physical samples along with specifications for material, color, finish, and functional requirements. Reputable suppliers will provide feasibility feedback, cost estimates, and digital renderings within 24–72 hours.