Example Of Manufacturing Operation

Top sponsor listing

Top sponsor listing

CN

CN

About example of manufacturing operation

Where to Find Manufacturing Operation Equipment Suppliers?

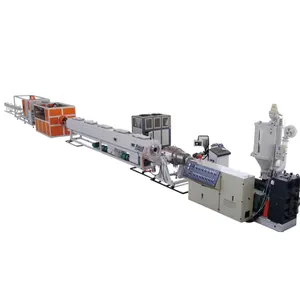

China remains the central hub for manufacturing operation equipment production, with key supplier clusters concentrated in Shandong, Henan, and Guangdong provinces. These regions host vertically integrated industrial ecosystems that support rapid prototyping and scalable production across diverse sectors—from food processing and plastics to metal forming and tobacco machinery. Shandong’s Laiwu and Luohe areas specialize in polymer processing lines, leveraging proximity to raw material suppliers to reduce input costs by 15–20%. Meanwhile, Shenzhen and surrounding Pearl River Delta zones focus on precision metalworking and automation systems, benefiting from mature electronics and mechanical component supply networks.

The clustering effect enables efficient coordination between upstream component manufacturers, engineering firms, and logistics providers—typically within a 50-kilometer radius. This integration supports shorter lead times (average 30–60 days depending on complexity), flexible MOQs, and cost-effective customization. Buyers gain access to facilities equipped with CNC machining, cold-rolling, extrusion, and automated assembly capabilities, allowing adaptation to both standard and specialized manufacturing workflows.

How to Choose Manufacturing Operation Equipment Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

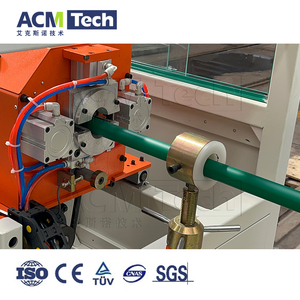

Confirm alignment between supplier offerings and process requirements. For plastic extrusion or blown film lines, verify control over critical parameters such as pipe diameter, wall thickness, layer count, and labeling options. In metal processing, assess machine specifications including roll diameter, speed, power source, and compatibility with materials like stainless steel or aluminum alloys. Request technical drawings, 3D models, or facility videos to validate engineering capacity.

Production & Quality Assurance Protocols

Prioritize suppliers demonstrating structured quality management practices. While formal certifications (e.g., ISO 9001, CE) are not universally listed, performance indicators such as on-time delivery rates (>94%) and response times (≤2 hours) serve as proxies for operational discipline. Evaluate whether suppliers conduct in-process inspections, final product testing, and maintain traceability records—especially for regulated industries like food or tobacco processing.

- Minimum viable factory scale: 1,000+ m² for dedicated production zones

- Evidence of R&D capability or customization experience

- In-house machining or assembly reduces dependency on subcontractors

- On-time delivery rate ≥94% indicates stable workflow management

Transaction Risk Mitigation

Utilize secure payment methods with milestone-based releases. Where available, engage third-party inspection services prior to shipment to verify functionality and conformance. Analyze reorder rates as an indicator of customer satisfaction—suppliers with reorder rates above 15% demonstrate consistent service delivery. For high-value orders (>$50,000), require detailed commissioning procedures and after-sales support agreements.

What Are the Best Manufacturing Operation Equipment Suppliers?

| Company Name | Specialization | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Laiwu Huaya Polymer Sci.&Tech. Co., Ltd. | Plastic Extrusion & Film Lines | Plastic Extruders, Blown Film Lines, Garden Hoses, Agricultural Films | Diameter, thickness, color, length, layers, packaging, labeling | US $10,000+ | 100% | ≤2h | 16% |

| Shenzhen Weiye Mechanical Equipment Co., Ltd. | Metal Forming & Automation | Spot Welding Lines, Roll Mills, Strapping Machines | Machine configuration, output capacity, automation level | US $220,000+ | 97% | ≤2h | <15% |

| Luohe Three Stones Machinery Co., Ltd. | Food Processing Systems | Bread, Chocolate, Candy, and Snack Production Lines | Output rate, size configuration, energy source | US $10,000+ | 94% | ≤2h | <15% |

| A.B.M. TOOLS | Cold Forging & Fastener Production | Bolt Making Machines, Rivet Production Units | Production speed, tooling compatibility, motor type | Not disclosed | Not available | ≤16h | Not available |

| Royermak Makina Ic Ve Dis Ticaret Limited Sirketi | Tobacco Machinery | Cigarette Manufacturing Machines (up to 20,000 pcs/min) | Output volume, pneumatic/electric systems, automation grade | Not disclosed | Not available | ≤3h | Not available |

Performance Analysis

Laiwu Huaya stands out with a 100% on-time delivery record and extensive customization capabilities in plastic extrusion, making it a strong candidate for long-term contracts requiring consistent quality. Shenzhen Weiye demonstrates higher transaction volume (over US$220,000 online revenue) and solid reliability (97% on-time delivery), suitable for buyers seeking proven metal processing solutions. Luohe Three Stones targets niche food manufacturing applications, offering turnkey chocolate and bread production systems at competitive pricing. A.B.M. TOOLS and Royermak cater to specialized industrial segments but lack verifiable performance metrics, suggesting higher due diligence requirements before engagement. Response times across leading suppliers average ≤2 hours, indicating strong customer service infrastructure.

FAQs

How to verify manufacturing operation equipment supplier reliability?

Assess on-time delivery history, response consistency, and transaction volume where available. Request references or case studies for similar projects. For critical applications, commission remote audits via video walkthroughs of production floors and quality control stations. Validate technical claims against product specifications and user manuals.

What is the typical lead time for manufacturing equipment?

Standard machines ship in 30–45 days after order confirmation. Customized systems, particularly those involving new molds or control programming, may require 60–90 days. High-capacity cigarette or food processing lines can extend beyond 100 days depending on complexity.

Do suppliers offer customization for manufacturing lines?

Yes, most suppliers provide configurable options including size, output rate, material compatibility, automation level, and safety features. Plastic extrusion and food processing suppliers typically allow adjustments to dimensions, power sources, and packaging interfaces. Confirm change-order policies and associated rework timelines before finalizing designs.

What are common MOQ and pricing structures?

MOQs vary by equipment type: single units for small-scale roll mills ($79–$2,750), full sets for automated production lines ($1,500–$85,000+). High-output systems (e.g., 20,000-piece-per-minute cigarette machines) start at $85,000 per unit. Some suppliers waive setup fees for orders exceeding five units or total values above $50,000.

Can suppliers support international shipping and installation?

Most established suppliers manage global freight via FOB or CIF terms and provide basic installation guides. For complex machinery, request commissioning support—some vendors offer remote troubleshooting or on-site technician deployment at additional cost. Ensure compliance with destination-country electrical, safety, and import standards prior to shipment.