Albertsons Key Maker

1/14

1/14

1/14

1/14

1/28

1/28

1/12

1/12

1/37

1/37

1/4

1/4

About albertsons key maker

Where to Find Albertsons Key Maker Suppliers?

China serves as the global hub for precision key-making machinery production, with Shenzhen emerging as a dominant center due to its concentrated electronics and locksmith equipment manufacturing ecosystem. The city’s industrial infrastructure supports rapid prototyping and scalable production of automated and manual key cutting systems, leveraging proximity to component suppliers and export logistics networks. Suppliers in this region specialize in both standalone key duplicating machines and integrated programmable systems compatible with automotive, residential, and commercial lock technologies.

Shenzhen-based manufacturers benefit from vertically integrated supply chains that reduce component lead times by 20–30% compared to non-specialized regions. These suppliers typically operate within compact but technologically advanced facilities, enabling quick turnaround on standard orders (15–25 days) and customization requests. With established export channels, they serve international retail and service providers, including those requiring private labeling or compatibility with branded hardware ecosystems such as Albertsons’ in-store key duplication services.

How to Choose Albertsons Key Maker Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

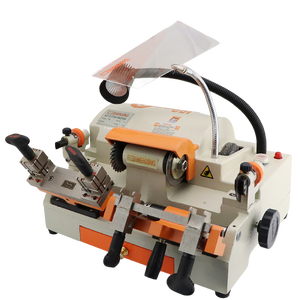

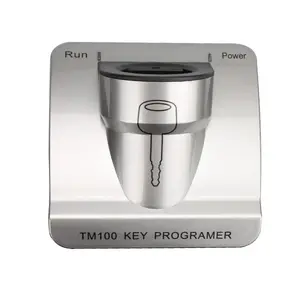

Assess whether suppliers offer machines compatible with common key profiles used in retail environments—particularly tubular, dimple, and transponder keys. Confirm support for 4D/4C laser-cutting technology if high-security automotive keys are required. Machines should be capable of handling brass, nickel-silver, and steel blanks with precision tolerances below ±0.02mm.

Production and Customization Capacity

Evaluate supplier capabilities based on:

- Minimum Order Quantity (MOQ): Ranges from 1–2 pieces for standard models, allowing low-volume testing

- Customization options: Look for suppliers offering OEM/ODM services including logo imprinting, packaging design, and voltage configuration (110V/220V)

- In-house R&D teams focused on locksmith tools and diagnostic integration

Cross-reference product listings with reorder rates above 25% and on-time delivery performance exceeding 97% to ensure reliability.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality control processes. While formal ISO 9001 certification may not always be listed, consistent on-time delivery (>97%) and sub-3-hour response times indicate operational discipline. Utilize secure payment mechanisms and request pre-shipment inspection rights. Conduct sample testing to verify machine durability, alignment accuracy, and ease of operator use before scaling procurement.

What Are the Best Albertsons Key Maker Suppliers?

| Company Name | Location | Online Revenue | Main Products | On-Time Delivery | Response Time | Reorder Rate | Product Range | MOQ |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Topbest Technology Co., Limited | Shenzhen, CN | US $420,000+ | Key Cutting Machines, Car Key Programmers | 99% | ≤2h | 32% | 5+ models ($56–$538) | 1–2 pcs |

| Shenzhen Talentcar Electronic Co., Ltd. | Shenzhen, CN | US $30,000+ | Auto Key Makers, Remote Programming Tools | 97% | ≤2h | 24% | 4 models ($60–$1,100) | 1 pc/set |

| Shenzhen Topbest Technology Co., Limited | Shenzhen, CN | US $320,000+ | Smart Key Makers, Automotive Cutters | 100% | ≤3h | 27% | 5 models ($12–$1,757) | 1–2 pcs |

| Shenzhen Xin An Sheng Electronic Co., Ltd. | Shenzhen, CN | US $270,000+ | Automatic Key Cutters, Locksmith Tools | 99% | ≤3h | <15% | 5 models ($150–$1,700) | 1–2 pcs |

| Shenzhen Zhuoyue Oude Electronic Technology Co., Ltd. | Shenzhen, CN | US $100,000+ | Car Key Programmers, Diagnostic Tools | 97% | ≤3h | <15% | 4 models ($74–$177) | 1 pc/set |

Performance Analysis

Shenzhen Topbest Technology stands out with dual entries indicating strong market presence, combining high reorder rates (32%), fast response times (≤2h), and broad product range—from entry-level cutters at $56 to professional-grade units near $1,700. Its 99–100% on-time delivery record reflects robust fulfillment systems. Shenzhen Xin An Sheng offers premium automatic cutting machines but has lower customer retention, suggesting potential gaps in post-sale support. Smaller-volume suppliers like Talentcar and Zhuoyue Oude focus on programmer-integrated solutions ideal for automotive-centric operations. Buyers seeking retail-compatible, cost-effective key makers should prioritize suppliers with MOQs of 1 piece and proven customization experience.

FAQs

How to verify Albertsons key maker supplier reliability?

Cross-check performance metrics such as on-time delivery rate (>97%), response time (<3 hours), and reorder rate (>25%) as proxies for service consistency. Request product specifications, operational manuals, and video demonstrations of machine function. Validate claims about material compatibility and cutting precision through independent sample testing.

What is the typical lead time for key maker machines?

Standard order fulfillment ranges from 15–25 days after confirmation. Sample units ship within 7–10 days. Air freight adds 5–8 days globally; sea freight takes 25–40 days depending on destination port and customs processing.

Can suppliers customize key making machines for retail branding?

Yes, multiple suppliers list customization options for logo, color, packaging, and label design. Voltage settings (110V/220V) can be configured for North American or international electrical standards. Confirm these capabilities during initial inquiry and request mockups prior to production.

Do suppliers provide technical support and training?

While formal training programs are rarely specified, responsive suppliers (≤2h average reply time) typically offer remote guidance via chat or email. Some include user manuals, instructional videos, or software interfaces to simplify setup and operation.

Are spare parts and maintenance components available?

Most suppliers stock critical wear components such as cutting wheels, vices, and motor assemblies. Inquire about availability of replacement kits and expected lifespan under continuous daily use (e.g., 8–10 hour shifts in retail settings).