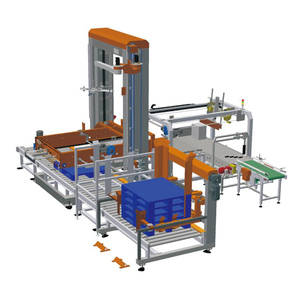

Arpac Palletizer

Top sponsor listing

Top sponsor listing

About arpac palletizer

Where to Find Arpac Palletizer Suppliers?

China serves as a central hub for automated material handling equipment manufacturing, with key supplier clusters in Shandong, Guangdong, and Jiangsu provinces. Shandong-based suppliers, such as Qingdao Ausense Packing Equipment Co., Ltd., specialize in integrated packaging lines featuring conveyor-integrated palletizers, leveraging regional access to steel and automation component suppliers that reduce production costs by 15–20%. Guangdong’s Shenzhen region hosts advanced robotics developers like Shenzhen Era Automation Co., Ltd., focusing on collaborative robot (cobot) integration for compact, high-precision palletizing systems.

These industrial zones support vertically aligned production ecosystems where structural fabrication, control system assembly, and final testing occur within consolidated facilities. This integration enables lead times averaging 30–45 days for standard units and facilitates rapid prototyping for customized configurations. Buyers benefit from scalable output, localized supply chains, and technical agility in adapting machines to specific load weights (ranging from 20kg to 30kg per cycle), pallet dimensions, and factory layouts. The concentration of engineering talent and component vendors within 50km radii enhances responsiveness and after-sales service efficiency.

How to Choose Arpac Palletizer Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional criteria:

Technical & Functional Compliance

Verify compatibility with existing production lines by confirming interface standards for conveyors, labeling systems, and warehouse management software. Demand CAD drawings and layout simulations prior to order placement. For international operations, ensure CE or equivalent safety certification for robotic systems and electrical controls. Confirm PLC brand specifications (e.g., Siemens, Mitsubishi) and HMI language support (English, Spanish, etc.).

Production Capability Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum factory area of 3,000m² for dedicated assembly lines

- In-house engineering teams capable of customizing robotic arm reach, gripper design, layer pattern logic, and integration with strapping/wrapping stations

- Proven experience in delivering turnkey solutions including conveyors, pallet dispensers, and stack height adjustment mechanisms

Cross-reference claimed capabilities with product listings showing customization options for color, material handling capacity, label integration, and dimension adjustments.

Transaction Risk Mitigation

Prioritize suppliers with documented quality management systems and third-party verification. Use secure payment escrow until site acceptance testing is completed. Analyze historical performance metrics: target on-time delivery rates ≥98%, reorder rates >20% indicating customer retention, and response times under 3 hours for technical inquiries. Request sample units for durability and cycle time validation, especially for high-throughput environments exceeding 10 layers per minute.

What Are the Best Arpac Palletizer Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Shandong, CN | Packaging Line, Wrapping Machines, Conveyors, Palletizers | US $1.2M+ | 100% | ≤2h | 18% | Yes (layout, material, logo, dimensions, color) | $9,900–$17,900 |

| Shenzhen Era Automation Co., Ltd. | Guangdong, CN | Collaborative Robots, AGV, Material Handling Systems | US $350K+ | 100% | ≤2h | 25% | Limited (focus on cobot integration) | $5,390–$17,900 |

| Focus Machinery Co., Ltd. | Zhejiang, CN | Automatic Palletizers, Packaging Lines, Labeling Machines | US $110K+ | 100% | ≤3h | <15% | Yes (output, size, weight, packaging parameters) | $4,500–$30,000 |

| Nanjing Brickmac Engineering Co., Ltd. | Jiangsu, CN | Robotic Palletizers, Brick Stacking Systems | US $30K+ | 100% | ≤5h | 50% | Yes (brick size, automation level, capacity) | $1,000–$4,500 |

| XINGPACK AUTOMATION CO., LTD | Shanghai, CN | Robot Palletizers (KUKA, ABB, FANUC), Packaging Lines | US $40K+ | 100% | ≤6h | <15% | Yes (brand-specific robotic integration) | $20,000–$55,000 |

Performance Analysis

Qingdao Ausense leads in revenue scale and customization breadth, making it suitable for buyers requiring full-line integration with detailed design flexibility. Shenzhen Era Automation offers competitive pricing on cobot-driven models with strong reorder performance, ideal for smart factory upgrades. Focus Machinery provides mid-range solutions with wide price variation, catering to diverse throughput needs. Nanjing Brickmac stands out with a 50% reorder rate despite lower online visibility, suggesting strong niche satisfaction in brick and block handling applications. XINGPACK targets premium installations with OEM-branded robotic arms (ABB, KUKA), justifying higher price points through proven industrial integration. All listed suppliers maintain 100% on-time delivery records, but response time varies significantly—prioritize those with ≤3h average replies for time-sensitive projects.

FAQs

How to verify Arpac palletizer supplier reliability?

Confirm ISO 9001 certification status and request evidence of CE-marked components. Review transaction history for consistent fulfillment performance. Conduct virtual audits via facility walkthrough videos highlighting CNC machining centers, wiring labs, and final testing bays. Validate after-sales support availability, including remote PLC troubleshooting and spare parts logistics.

What is the typical lead time for custom palletizers?

Standard models ship within 30 days. Custom configurations involving non-standard pallet patterns, extended reach arms, or multi-conveyor interfaces require 45–60 days. Prototype development takes 3–4 weeks following receipt of technical specifications.

Do suppliers offer MOQ flexibility?

Most suppliers list a minimum order quantity of 1 set, enabling pilot deployments. Bulk discounts typically apply at 5+ units. Some manufacturers waive setup fees for repeat orders or long-term service agreements.

Can Arpac palletizers integrate with existing ERP/MES systems?

Higher-tier suppliers provide OPC UA or Modbus TCP connectivity for real-time data exchange with SAP, Oracle, or local MES platforms. Confirm communication protocol support during technical scoping. Integration kits may incur additional costs.

How to initiate a customization request?

Submit detailed requirements including load weight (up to 1,500kg), pallet dimensions (standard EUR/ISO or custom), stacking pattern (interlocking, column, etc.), cycle time targets, and environmental conditions (dusty, humid, outdoor). Reputable suppliers respond with 3D layout proposals and electrical schematics within 72 hours.