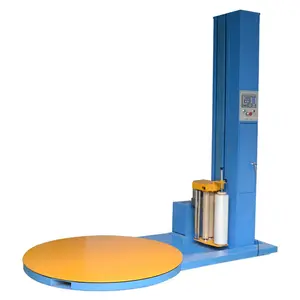

Semi Automatic Pallet Wrapper

Top sponsor listing

Top sponsor listing

About semi automatic pallet wrapper

Where to Find Semi Automatic Pallet Wrapper Suppliers?

China remains the global epicenter for semi-automatic pallet wrapper manufacturing, with concentrated production hubs in Shandong, Jiangsu, and Guangdong provinces. These regions host vertically integrated supply chains that combine precision engineering, polymer film processing, and automated assembly under one ecosystem. Shandong’s Jining and Linyi zones specialize in heavy-duty wrapping machinery, supported by regional steel and electrical component suppliers that reduce material procurement cycles by 20–25%. Meanwhile, manufacturers in Nantong (Jiangsu) and Foshan (Guangdong) focus on compact, user-integrated designs suited for mid-volume logistics operations.

The industrial clusters enable rapid prototyping and scalable production, with many facilities operating CNC machining centers, welding bays, and in-house testing lines within 5,000–25,000m² plants. This integration supports average lead times of 15–30 days for standard units and accelerates customization turnaround. Buyers benefit from localized access to stretch film extrusion partners, load simulation labs, and certification bodies—reducing dependency on external vendors and improving cost efficiency by up to 30% compared to non-specialized markets.

How to Choose Semi Automatic Pallet Wrapper Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to international safety and performance benchmarks. CE marking is essential for European market entry, while ISO 9001 certification indicates formalized quality management systems. Request test reports for motor durability, film tension control, and structural load capacity (typically rated for 2,000–3,000 kg loads). Verify compliance with RoHS directives where applicable, particularly for electronic control panels.

Production Capacity Assessment

Evaluate core infrastructure indicators:

- Facility size exceeding 3,000m² to support batch production

- In-house fabrication capabilities including CNC cutting, robotic welding, and PLC programming

- Dedicated R&D or engineering teams for custom modifications

Cross-reference these metrics with on-time delivery rates—prioritize suppliers maintaining ≥97% fulfillment punctuality—as a proxy for operational stability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial release with shipment milestones. Analyze reorder rates (a proxy for customer satisfaction) and response times (≤2 hours preferred) to gauge service reliability. Conduct pre-shipment inspections or request factory audit videos to validate production conditions. For critical applications, require sample testing under simulated load conditions before scaling orders.

What Are the Best Semi Automatic Pallet Wrapper Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Verified Supplier |

|---|---|---|---|---|---|---|---|

| Linyi Glory New Material Co., Ltd. | Plastic Film Strapping Wrapping Machines, Adhesive Tapes | US $130,000+ | 91% | ≤2h | 19% | Color, material, size, thickness, logo, packaging, graphic dimensions | Multispecialty Supplier |

| Nantong Huabo Technology Co., Ltd. | Wrapping Machines, Sealing & Vacuum Packing Equipment | US $20,000+ | 100% | ≤2h | 20% | Not specified | - |

| Foshan Lido Pack Co., Ltd. | Wrapping Machines, Plastic Film Strapping, Sealing Systems | US $70,000+ | 100% | ≤1h | <15% | Not specified | - |

| Jining Keepway Machinery Company Ltd. | Wrapping Machines, Labeling & Multi-Function Packaging Systems | US $600,000+ | 97% | ≤2h | 36% | Not specified | - |

| Foshan Jiajun Willie Pak Co., Ltd. | Plastic Film Wrapper Tools, Industrial Packaging Equipment | US $70,000+ | 98% | ≤2h | <15% | Color, size, roll size, logo, model, battery, packaging, label, inner core | Multispecialty Supplier |

Performance Analysis

Jining Keepway Machinery leads in customer retention with a 36% reorder rate and robust US$600,000+ annual online revenue, signaling strong market trust and repeat demand. Nantong Huabo and Foshan Lido achieve perfect on-time delivery records (100%), with Foshan Lido offering the fastest average response time (≤1h), indicating high operational responsiveness. Linyi Glory and Foshan Jiajun provide extensive customization options—critical for buyers requiring branded or dimensionally specific solutions. While some suppliers report lower reorder rates (<15%), this may reflect niche positioning or single-project engagements rather than performance deficiencies.

FAQs

How to verify semi automatic pallet wrapper supplier reliability?

Cross-check ISO and CE certifications with issuing authorities and request product conformity declarations. Review transaction history for consistent on-time delivery (>97%) and short response cycles (≤2h). Prioritize suppliers offering third-party inspection rights and documented quality control procedures.

What is the typical minimum order quantity (MOQ) and pricing range?

Standard MOQ is 1 set or piece across most suppliers. Unit prices vary by configuration: basic turntable models start at $79–$450, mid-range semi-automatic systems range from $1,200–$1,850, while advanced rotary-arm or side-seal variants reach $2,800. Volume discounts apply for container-load orders.

Can suppliers customize machine specifications?

Yes, leading suppliers offer customization in color, film compatibility (LLDPE, PP, pre-stretched), turntable diameter (up to 2,000 mm), load height (max 3,000 mm), control panel language, and branding elements (logo, labeling). Confirm feasibility via technical drawings before order placement.

What are the average production and shipping lead times?

Manufacturing lead time ranges from 10–25 days depending on customization level. Air freight delivers samples within 7–10 days; sea freight for bulk shipments takes 20–35 days to major global ports. Confirm FOB or CIF terms during quotation.

Do suppliers provide after-sales support and technical documentation?

Most suppliers supply operation manuals, wiring diagrams, and basic troubleshooting guides. Warranty periods typically range from 12–24 months. Availability of remote guidance or on-site service depends on buyer location and contract scale—clarify support scope prior to purchase.