Automatic Palletizer Machine Exporters

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/23

1/23

1/3

1/3

1/3

1/3

0

0

1/3

1/3

About automatic palletizer machine exporters

Where to Find Automatic Palletizer Machine Exporters?

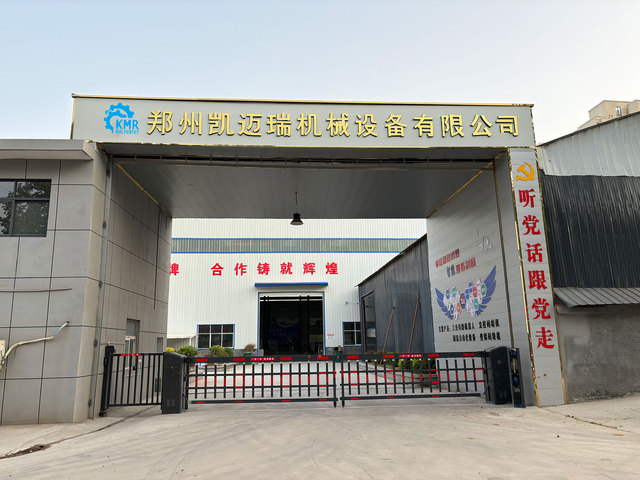

China remains the global epicenter for automatic palletizer machine manufacturing, with key industrial hubs concentrated in Shandong and Shanghai. These regions host vertically integrated production ecosystems that combine precision engineering, automation R&D, and robust material handling supply chains. Shandong, particularly Qingdao and Jining, specializes in high-capacity robotic palletizing systems, leveraging proximity to steel and logistics infrastructure to reduce component costs by 15–25%. Shanghai’s advanced automation cluster supports complex system integration, including conveyor synchronization and AI-driven stacking logic, enabling faster deployment of turnkey packaging lines.

Suppliers in these zones operate within tightly networked ecosystems where design, fabrication, assembly, and testing occur under one roof. This integration reduces lead times to 30–45 days for standard configurations and allows flexible scaling for bulk orders. Buyers benefit from localized access to CNC machining, robotic arm suppliers, and control system integrators, minimizing dependency on external vendors. The region’s export maturity ensures compliance with international electrical and safety standards, facilitating smooth customs clearance in North America, Europe, and Southeast Asia.

How to Choose Automatic Palletizer Machine Exporters?

Selecting a reliable exporter requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Customization Capability

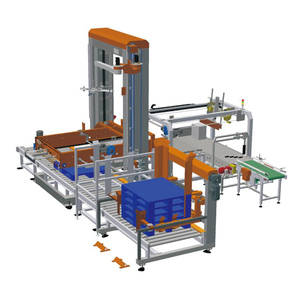

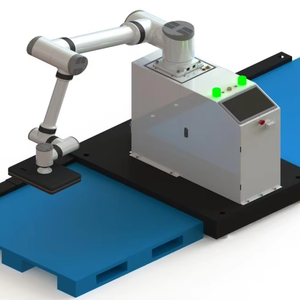

Verify that suppliers offer CAD-based layout design, robotic arm integration, and compatibility with existing conveyor systems. Leading exporters provide customization for pallet size, load weight (up to 1,500 kg), strapping method, labeling systems, and color schemes. Confirm support for multiple product types—bags, cases, cartons, or drums—and ability to generate 3D renderings within 72 hours of inquiry.

Production & Quality Assurance

Assess manufacturing infrastructure through available indicators:

- Minimum factory area supporting dedicated assembly lines for robotic and column-type palletizers

- In-house engineering teams capable of PLC programming and HMI interface development

- Use of certified components (e.g., Siemens/Allen Bradley controls, ABB/KUKA robotic arms)

- On-time delivery performance exceeding 95% as an indicator of production planning rigor

Ideally, suppliers should adhere to ISO 9001 quality management standards, though explicit certification data is not always disclosed. Prioritize those documenting testing procedures for cycle durability, alignment accuracy, and emergency stop response.

Export Readiness & Transaction Security

Evaluate responsiveness (target ≤2 hours) and reorder rate as proxies for customer satisfaction. High reorder rates (>25%) suggest reliability and after-sales support effectiveness. Use secure payment mechanisms such as escrow services and require pre-shipment inspection clauses. Confirm FOB or CIF shipping terms and experience with containerized machinery export, including crating and marine insurance coordination.

What Are the Best Automatic Palletizer Machine Exporters?

| Company Name | Verified Type | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Custom Manufacturer | Packaging Line, Wrapping Machines, Conveyors, Material Handling | US $1,300,000+ | 100% | ≤2h | 22% | $10,000–75,000 | Yes (size, color, logo, layout, material, graphic) |

| Finopack Technology Co., Ltd. | Not Specified | Multi-Function Packaging Machines, Wrapping Machines | US $220,000+ | 100% | ≤10h | <15% | $26,000–75,000 | Limited |

| Shanghai Gebo Machinery Co., Ltd. | Multispecialty Supplier | Wrapping, Palletizing, Semi-Automatic Systems | US $40,000+ | 92% | ≤1h | 17% | $10,000–15,000 | Yes (color, material, size, logo, label) |

| Jiangyin Tianshili Industry Automation Co., Ltd. | Not Specified | Industrial Robots, Linear Robots, Packaging Lines | US $5,000+ | 100% | ≤3h | 100% | $12,000–12,900 | Yes (column-type, case, robot stacking) |

| Jining Shunyin Machinery Co., Ltd. | Multispecialty Supplier | Column-Type, Bag, Carton Palletizers | US $770,000+ | 98% | ≤1h | 31% | $6,900–8,750 | Yes (carton size, color, material, logo) |

Performance Analysis

Qingdao Ausense stands out for high revenue volume, full customization, and perfect on-time delivery, positioning it as a top-tier exporter for large-scale automated lines. Jiangyin Tianshili demonstrates exceptional customer retention with a 100% reorder rate, indicating strong post-sale satisfaction despite lower online revenue visibility. Jining Shunyin offers competitive pricing and fast response times, making it suitable for cost-sensitive buyers seeking semi-automatic solutions. Finopack provides higher-end models (up to $75,000), suggesting specialization in high-speed, fully automated systems, though its slower response time may impact project timelines. Shanghai Gebo, while responsive and customizable, shows a lower on-time delivery rate (92%), warranting closer shipment monitoring.

FAQs

What certifications should automatic palletizer exporters have?

While not all suppliers list certifications explicitly, prioritize those compliant with CE standards for electrical safety and mechanical design. ISO 9001 indicates structured quality management. For North American markets, UL-listed control panels and OSHA-aligned guarding are critical for regulatory acceptance.

What is the typical lead time for automatic palletizer machines?

Standard units require 30–45 days after deposit confirmation. Custom-engineered systems, especially those integrating conveyors or robotics, may take 60–75 days. Expedited builds (as low as 20 days) are possible with premium fees and confirmed component availability.

Do exporters offer customization for integration with existing lines?

Yes, leading suppliers provide CAD drawings, PLC interface protocols, and I/O mapping to ensure seamless integration. Customizations include pallet dispenser synchronization, label applicator triggers, and SCADA connectivity for centralized monitoring.

What are common MOQ and pricing structures?

Most exporters set MOQ at 1 set, allowing pilot procurement. Pricing varies by automation level: semi-automatic column palletizers start at $6,900, while robotic systems exceed $25,000. Volume discounts typically apply for 3+ units, with potential savings of 8–12%.

How can buyers verify machine performance before purchase?

Request video demonstrations of live operation, including load stability tests and changeover procedures. Some suppliers offer sample runs using customer-specific load profiles. Third-party inspection services (e.g., SGS, BV) can validate build quality and safety compliance pre-shipment.