Automatic Palletizing System Exporter

Top sponsor listing

Top sponsor listing

CN

CN

About automatic palletizing system exporter

Where to Find Automatic Palletizing System Exporters?

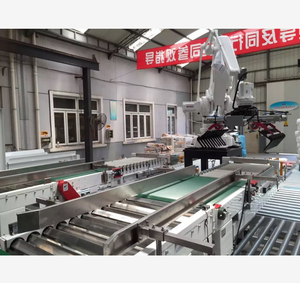

China remains the global hub for automated material handling equipment, with key manufacturing clusters in Shandong and Henan provinces driving innovation and export capacity in automatic palletizing systems. Shandong, particularly Qingdao, hosts vertically integrated facilities specializing in robotic arms, conveyor integration, and turnkey packaging lines, supported by mature steel and automation component supply chains. This regional synergy reduces production lead times by 15–20% compared to non-specialized regions.

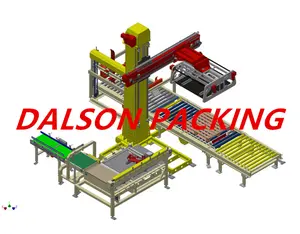

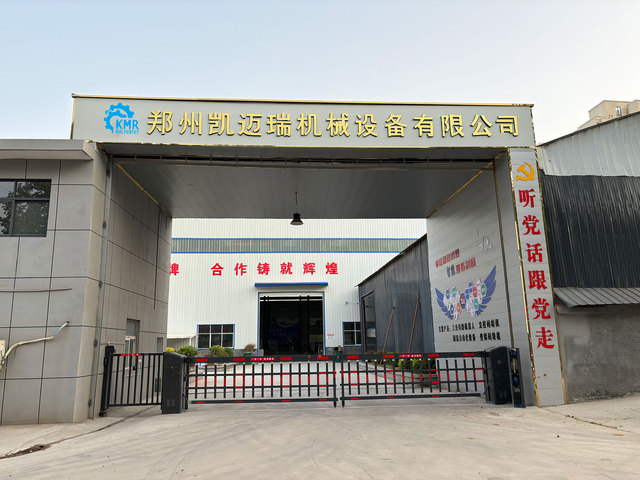

Henan's automation corridor, centered around Zhengzhou, focuses on cost-efficient, high-volume production of compact and column-type palletizers. The region’s dense network of electrical component suppliers and servo motor manufacturers enables rapid assembly and testing cycles. Buyers benefit from scalable output—facilities routinely support monthly production runs exceeding 50 units—with average delivery windows of 30–45 days for standard configurations. Proximity to inland rail hubs further enhances export logistics efficiency across Europe and Southeast Asia.

How to Choose Automatic Palletizing System Suppliers?

Selecting a reliable exporter requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Customization Capability

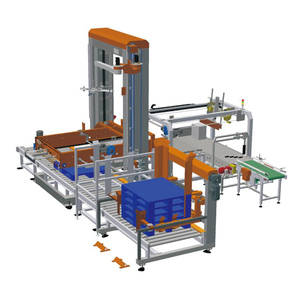

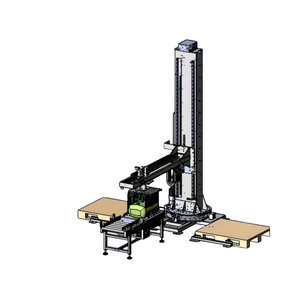

Verify suppliers offer comprehensive design flexibility, including adjustable pallet sizes, robotic arm reach, load capacity (typically 10–1,000 kg), and integration with existing conveyors or labeling systems. Leading exporters provide CAD layout drawings, 3D modeling, and material flow simulations prior to order confirmation. Confirm compatibility with diverse packaging types—cartons, drums, bags, and buckets—as demonstrated in product listings.

Production Infrastructure Assessment

Evaluate supplier infrastructure through objective indicators:

- Minimum factory area supporting dedicated R&D and assembly zones

- In-house engineering teams capable of system integration (e.g., PLC programming, HMI interface design)

- Proven track record in delivering multi-component systems (pallet dispensers, strapping units, robotic stackers)

Cross-reference response time (≤2 hours preferred) and on-time delivery rate (>97%) as proxies for operational reliability.

Quality Assurance & Export Readiness

Prioritize suppliers adhering to international quality management standards. While ISO 9001 certification is not explicitly stated in available data, consistent 100% on-time delivery among top performers suggests robust internal controls. For CE-regulated markets, confirm compliance documentation for motors, control panels, and safety interlocks. Request test reports for cycle durability (≥10,000 operational hours) and vibration resistance during transit.

What Are the Top Automatic Palletizing System Exporters?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Shandong, CN | Packaging Line, Wrapping Machines, Conveyors, Robotic Palletizers | US $1,200,000+ | 100% | ≤2h | 24% | $6,799–$40,000+ | Yes (layout, dimensions, material, logo, CAD drawings) |

| Bremetz (Shandong) Machinery Co., Ltd. | Shandong, CN | Column Palletizers, Articulated Robots, Filling Machines | Data Unavailable | 100% | ≤4h | No Data | $1,199–$12,000 | Limited (product-specific) |

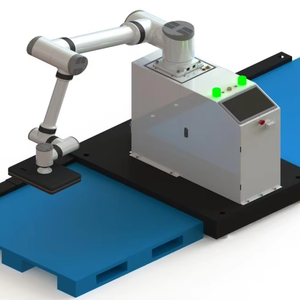

| Henan Xintu Automation Equipment Co., Ltd. | Henan, CN | Automatic Column Palletizers, Collaborative Robots | US $50,000+ | 100% | ≤1h | <15% | $13,000–$24,500 | Moderate (configuration-based) |

| XINGPACK AUTOMATION CO., LTD | Henan, CN | Robot Palletizers for Barrels, Oil Buckets, Drums | US $7,000+ | 100% | ≤5h | <15% | $9,500–$50,000 | Application-specific customization |

Performance Analysis

Qingdao Ausense stands out with the highest reported online revenue and extensive customization capabilities, positioning it as a strategic partner for complex, integrated palletizing lines. Its 24% reorder rate indicates moderate customer retention, likely due to mid-tier pricing and responsive service (≤2h). Henan Xintu excels in responsiveness (≤1h) and competitive mid-range pricing, ideal for buyers prioritizing communication speed and value.

Bremetz offers entry-level column palletizers starting below $1,200, catering to small-scale operations or niche applications like animal feed bagging. XINGPACK specializes in heavy-duty drum and barrel handling systems, with premium pricing reflecting application-specific engineering. All four suppliers report 100% on-time delivery, suggesting strong production planning discipline despite varying scale.

FAQs

What is the typical MOQ and lead time for automatic palletizing systems?

Minimum order quantity is generally 1 set, accommodating pilot projects and single-line installations. Lead times range from 20–45 days depending on complexity, with additional 7–14 days for international shipping via sea freight. Expedited builds may be available for urgent deployments.

Do suppliers offer customization for integration with existing lines?

Yes, leading exporters provide full system integration services, including conveyor synchronization, label verification linkage, and SCADA/PLC compatibility. Technical specifications such as pallet dimensions, weight capacity, stacking pattern, and robot reach can be tailored. CAD layouts and process flow diagrams are typically provided pre-shipment.

Are samples available before bulk ordering?

Full-system sampling is uncommon due to size and cost; however, suppliers may offer video demonstrations, factory test runs, or partial subsystem validation. Some provide prototype programming based on client throughput requirements. Sample fees, if charged, are often credited toward formal orders.

What payment and transaction protections are available?

Standard terms include T/T (30% deposit, 70% before shipment) or L/C at sight. Buyers should insist on inspection clauses allowing third-party or on-site performance verification prior to final payment. Escrow or trade assurance mechanisms mitigate financial risk in cross-border transactions.

How do I verify a supplier’s technical competence?

Request detailed technical proposals, including component brands (e.g., Mitsubishi PLC, ABB/FANUC robots), motor specifications, and safety certifications. Conduct virtual audits with live camera tours of assembly floors and testing bays. Validate past project references, especially in your industry vertical (food, chemicals, automotive).