Assembly Automation And Product Design

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

About assembly automation and product design

Where to Find Assembly Automation and Product Design Suppliers?

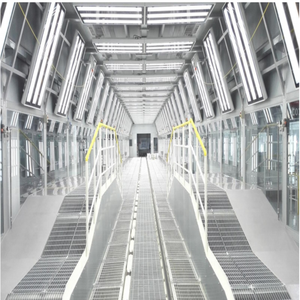

China's industrial automation sector is anchored by specialized manufacturing clusters in Shandong, Henan, and Guangdong provinces, each offering distinct advantages for assembly line systems and integrated product design. Shandong excels in laser-based metal processing and heavy-duty automation infrastructure, with suppliers leveraging proximity to steel production hubs to reduce material costs by 15–20%. Henan has emerged as a center for automotive and electronics-focused assembly solutions, supported by a deep pool of mechanical engineers and modular production facilities. Guangdong’s Pearl River Delta region leads in high-precision electronics automation and robotic integration, benefiting from dense supplier networks for servo motors, control systems, and custom fabrication.

These regional ecosystems enable vertically integrated production—from structural framing and conveyor systems to PLC programming and end-of-arm tooling—allowing suppliers to deliver turnkey automation solutions within 45–90 days. Buyers benefit from localized supply chains where component sourcing, machining, and system testing occur within compact geographic radii, reducing logistics overhead and enabling rapid prototyping. Key efficiencies include scalable output (from single-line installations to full plant layouts), 20–30% cost savings versus Western equivalents, and strong capabilities in both standard configurations and engineered-to-order systems.

How to Choose Assembly Automation and Product Design Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Engineering & Design Capability

Confirm suppliers possess in-house R&D teams capable of integrating mechanical, electrical, and software components. Prioritize those offering 3D modeling, simulation testing, and flexible line design for mixed-model production. Verify experience in your target industry—automotive, energy storage, or consumer electronics—as process requirements vary significantly.

Production Infrastructure Validation

Assess core manufacturing competencies through the following criteria:

- Facility size exceeding 3,000m² to support large-scale assembly projects

- In-house capabilities in welding, CNC machining, and control panel fabrication

- Demonstrated use of aluminum profiles, stainless steel strips, and laser welding for durable system construction

Cross-reference facility scale with on-time delivery performance (target ≥95%) and response time (ideally ≤8 hours) to gauge operational responsiveness.

Quality Assurance & Transaction Security

While formal ISO 9001 certification is not universally declared in available data, prioritize suppliers with documented quality control processes, including pre-shipment functional testing and traceable component sourcing. Utilize secure payment mechanisms that link disbursement to milestone verification. Request video walkthroughs of completed installations and conduct sample testing—particularly for critical parameters like cycle time accuracy and fault recovery protocols—before scaling procurement.

What Are the Best Assembly Automation and Product Design Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Zhejiang Jianggong Automation Equipment Co., Ltd. | Zhejiang, CN | Assembly Line | 100% | ≤17h | <15% | - | Not specified |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Henan, CN | Assembly Line, Other Processing Line, Welding Equipment | 100% | ≤8h | - | - | Not specified |

| Dongguan Yicheng Automation Equipment Co., Ltd. | Guangdong, CN | Assembly Line, Electronics Production Machinery, Commercial Robots | 100% | ≤6h | - | - | Not specified |

| Guangdong Chaomai Automation Technology Co., Ltd. | Guangdong, CN | Industrial Robots, Conveyor Systems, Aluminum Profile Lines | 100% | ≤2h | 60% | US $270,000+ | Color, material, size, logo, packaging, label, graphic |

| Shandong Huiyao Laser Technology Co., Ltd. | Shandong, CN | Laser Welders, Stainless Steel Strips, Energy Storage Systems | 66% | ≤2h | <15% | US $10,000+ | Not specified |

Performance Analysis

Suppliers such as Zhejiang Jianggong, Zhengzhou Duoyuan, and Dongguan Yicheng demonstrate perfect on-time delivery records, indicating strong project execution discipline despite limited reorder rate transparency. Guangdong Chaomai stands out with a 60% reorder rate and extensive customization options, suggesting high customer satisfaction and adaptability in system design. Its sub-2-hour response time further enhances service agility. In contrast, Shandong Huiyao reports a lower 66% on-time delivery rate, signaling potential fulfillment risks despite competitive pricing and laser-processing expertise. Regional trends show Guangdong-based firms leading in responsiveness and after-sales engagement, while Henan and Zhejiang suppliers focus on large-scale industrial lines for automotive and energy applications.

FAQs

How to verify assembly automation supplier reliability?

Request evidence of completed installations, preferably in your target application area. Validate technical claims through live demonstrations or factory audit videos. Analyze response consistency, order fulfillment history, and customization depth. For high-value contracts, engage third-party inspection services prior to shipment.

What is the typical lead time for automated assembly lines?

Standard systems require 45–60 days for manufacturing and testing. Customized or large-scale production lines (e.g., EV battery pack assembly) may take 75–90 days. Add 10–20 days for international shipping depending on destination and freight mode.

Do suppliers offer design and engineering support?

Yes, most established suppliers provide full-cycle design services including layout planning, equipment integration, and PLC programming. Top-tier providers offer 3D renderings within 72 hours and prototype validation within 3–4 weeks.

What are common customization options?

Suppliers typically allow modifications in line length, speed, load capacity, material handling fixtures, control interfaces, and safety enclosures. Advanced vendors support branding elements such as color schemes, logos, and user interface graphics, particularly for turnkey factory deployments.

What are typical MOQ and pricing structures?

Minimum order quantities range from 1 meter (for conveyor segments) to full-line installations starting at $24,000. High-end automotive or EV assembly systems exceed $200,000 per unit. Some suppliers offer modular pricing, allowing phased deployment based on production volume needs.