Electronics Assembly Automation

CN

CN

CN

CN

CN

CN

CN

CN

About electronics assembly automation

Where to Find Electronics Assembly Automation Suppliers?

China remains the global epicenter for electronics assembly automation manufacturing, with key industrial hubs concentrated in Guangdong, Jiangsu, and Tianjin. The Pearl River Delta—centered on Shenzhen and Dongguan—hosts over 70% of China’s electronics production machinery suppliers, benefiting from proximity to semiconductor fabs, PCB fabricators, and tier-one EMS providers. This regional integration reduces component procurement lead times by 25–40% compared to offshore alternatives.

These clusters feature vertically integrated ecosystems where automation OEMs operate alongside precision machining workshops, control system developers, and testing laboratories within a 30km radius. This co-location enables rapid prototyping, just-in-time delivery, and agile customization for SMT lines, robotic assembly cells, and automated test equipment. Buyers gain access to mature supply chains capable of delivering full turnkey systems within 45–60 days, with cost advantages averaging 20–35% over European or North American manufacturers.

How to Choose Electronics Assembly Automation Suppliers?

Procurement decisions should be guided by structured evaluation criteria to mitigate technical and operational risks:

Technical Compliance & Certifications

Verify adherence to international quality standards such as ISO 9001 for quality management and ISO 13849 for machinery safety. For export to regulated markets, ensure compliance with CE (EU), UL (North America), or RoHS directives for hazardous substance restrictions. Request documentation for PLC firmware validation, electrical safety testing, and ESD-safe design where applicable.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area exceeding 3,000m² for dedicated assembly and testing zones

- In-house engineering teams supporting custom line integration (e.g., pick-and-place + AOI + reflow)

- Proven experience with high-mix, low-volume (HMLV) or high-volume production configurations

- Integration capabilities for Industry 4.0 features: IoT-enabled monitoring, MES connectivity, predictive maintenance

Cross-reference declared capabilities with on-time delivery performance (target ≥95%) and response time metrics (≤3 hours preferred).

Transaction & Quality Safeguards

Utilize secure payment mechanisms such as escrow services or letter of credit terms for initial large orders. Prioritize suppliers offering pre-shipment inspection protocols, including FAT (Factory Acceptance Testing) reports and video walkthroughs of fully operational lines. Request sample units or modular subsystems to validate precision, cycle time, and fault rate before scaling procurement.

What Are the Best Electronics Assembly Automation Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Dongguan Yicheng Automation Equipment Co., Ltd. | Guangdong, CN | Full-automatic assembly lines, motor armature production systems | $50,000–80,000 | 1 set | 100% | ≤7h | - | - |

| Guangdong Borunte Robot Technology Co., Ltd. | Guangdong, CN | Industrial robotic arms, CNC material handling systems | $999–5,999 | 1 set | 66% | ≤3h | 100% | US $20,000+ |

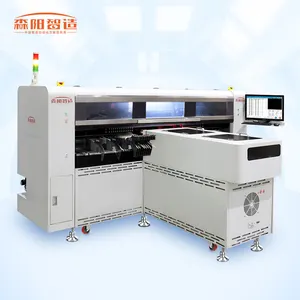

| Shenzhen Sun Young Intelligent Manufacturing Equipment Co., Limited | Guangdong, CN | SMT fully automatic machinery, LED strip assembly machines | $15,800–28,000 | 1 piece | 100% | ≤3h | - | US $900+ |

| Tianjin Huachuanyuan Electronic Sales Co., Ltd. | Tianjin, CN | Fully automatic SMT lines, PCB assembly systems | $98,000–180,000 | 1 set | 100% | ≤2h | - | US $2,000+ |

| Shanghai Detall Electronics Technology Co., Ltd. | Shanghai, CN | ESD conveyor lines, anti-static assembly workstations | $1,100–2,200 | 1 acre | 100% | ≤2h | 16% | US $320,000+ |

Performance Analysis

High-end system integrators like Dongguan Yicheng and Tianjin Huachuanyuan specialize in turnkey SMT and full-line automation solutions priced above $50,000, with 100% on-time delivery records indicating reliable project execution. In contrast, Borunte Robotics targets modular automation with compact robotic arms under $6,000, achieving a 100% reorder rate—suggesting strong customer satisfaction for component-level integration. Shenzhen Sun Young offers mid-range SMT automation at competitive pricing ($15k–28k), ideal for SMEs upgrading from manual processes. Shanghai Detall provides entry-level conveyors and ESD-compliant workstations, notable for high online transaction volume despite lower reorder rates, reflecting transactional rather than strategic buyer engagement.

FAQs

How to verify electronics assembly automation supplier reliability?

Validate certifications through official registries and request audit trails for critical subsystems (e.g., servo drives, vision systems). Conduct virtual factory audits to observe CNC machining, control panel assembly, and final system testing. Analyze customer reviews focusing on after-sales support, software stability, and mean time between failures (MTBF).

What is the typical lead time for custom automation lines?

Standard configurations ship in 30–45 days. Custom SMT or robotic integration projects require 50–75 days, including design approval, component sourcing, and FAT. Complex multi-station lines with MES integration may extend to 90 days.

Do suppliers support global shipping and installation?

Most established suppliers offer FOB or CIF shipping globally. Top-tier vendors provide remote commissioning support and on-site technician deployment (at additional cost). Confirm inclusion of manuals, spare parts kits, and training modules in the contract.

Can buyers request customization for specific production needs?

Yes, suppliers accept technical specifications for throughput (UPH), footprint constraints, feeder types, and compatibility with existing ERP/MES platforms. Reputable vendors provide 3D layout simulations within 5–7 business days and prototype builds within 4 weeks for validation.

What are common MOQ and pricing models?

MOQ is typically 1 set or unit, even for high-value systems. Pricing scales with automation level: semi-automatic stations start under $2,000, while fully integrated SMT lines exceed $100,000. Volume discounts apply for multiple-line deployments or repeat purchases.