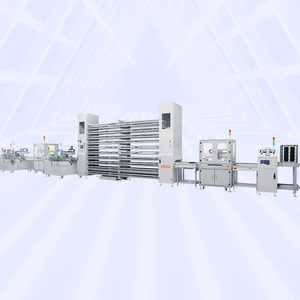

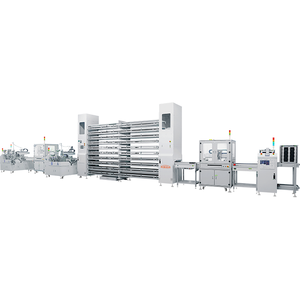

Automated Electronics Assembly Line

Top sponsor listing

Top sponsor listing

CN

CN

About automated electronics assembly line

Where to Find Automated Electronics Assembly Line Suppliers?

China remains the global epicenter for automated electronics assembly line manufacturing, with Shenzhen emerging as a dominant hub due to its deep integration within the Pearl River Delta's high-tech supply chain. This region hosts a dense network of industrial automation specialists offering end-to-end solutions—from component placement systems to fully integrated SMT and through-hole production lines. Proximity to semiconductor suppliers, PCB fabricators, and logistics infrastructure enables rapid prototyping and scalable deployment.

The Shenzhen ecosystem supports both standardized and highly customized automation configurations, leveraging vertical integration across mechanical design, control systems engineering, and after-sales technical support. Buyers benefit from compressed lead times (typically 30–60 days depending on complexity), access to modular system upgrades, and competitive pricing driven by localized sourcing of motion components, sensors, and vision systems. The cluster effect allows suppliers to offer comprehensive workshop planning services, including layout optimization and throughput analysis, enhancing overall production efficiency.

How to Choose Automated Electronics Assembly Line Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm expertise in core processes such as pick-and-place, reflow soldering, AOI (Automated Optical Inspection), and conveyor synchronization. Prioritize suppliers demonstrating experience with high-mix/low-volume or high-speed production environments. Request validation of machine accuracy (e.g., placement precision ±0.025mm), cycle time benchmarks, and compatibility with common CAD/CAM and MES interfaces.

Production Infrastructure Assessment

Evaluate supplier capacity based on facility scale and engineering resources:

- Proven track record in delivering turnkey assembly lines (not just individual machines)

- In-house R&D teams capable of customizing feeder configurations, handling special-shaped components, or integrating legacy equipment

- Workshop-based testing capabilities for dry runs prior to shipment

Cross-reference online revenue indicators and order fulfillment rates to assess operational stability and scalability.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE, RoHS) are essential for compliance, real-world performance metrics provide deeper insight. Focus on verified on-time delivery rates (>95% preferred), response times (<5 hours acceptable, ≤2 hours ideal), and reorder behavior. Utilize secure payment mechanisms that align payments with milestone verification, particularly for large-scale installations. Pre-shipment inspections and remote video audits mitigate risks associated with long-distance procurement.

What Are the Best Automated Electronics Assembly Line Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Support | Refurbished Options | After-Sales Service |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Extension Electromechanical Co., Ltd. | Electronics Production Machinery (637) | 100% | ≤2h | 38% | US $120,000+ | Yes | Yes | Workshop planning, lead time optimization |

| Shenzhen Ty Electronic Technology Co., Ltd. | Electronics Production Machinery (2331) | 66% | ≤3h | <15% | US $2,000+ | Limited | No | Basic technical support |

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Other Machinery & Industrial Equipment (417) | 100% | ≤5h | 100% | US $2,000+ | Yes | No | Custom plant design, full-line integration |

| Shenzhen Hongxinteng Technology Co., Ltd. | Electronics Production Machinery (253) | 100% | ≤5h | <15% | US $70,000+ | Yes | Yes | Equipment commissioning support |

| Shenzhen Sun Young Intelligent Manufacturing Equipment Co., Limited | Electronic Products Machinery (67) | 100% | ≤3h | - | US $900+ | Yes | No | Customizable LED-specific lines |

Performance Analysis

Shenzhen Extension Electromechanical stands out with the highest online revenue and strong reorder activity, supported by fast response times and proven delivery reliability. Its extensive product range suggests robust inventory and engineering bandwidth for complex integrations. Shenzhen Tianluo Automation demonstrates exceptional customer retention (100% reorder rate), indicating high satisfaction with customization outcomes despite moderate responsiveness. Multiple suppliers report 100% on-time delivery, though this should be validated against order volume and geographic shipping patterns. Buyers seeking refurbished or cost-optimized systems should prioritize suppliers explicitly listing such options, while those requiring full-line integration must verify experience in factory-wide workflow design.

FAQs

What is the typical MOQ and lead time for automated electronics assembly lines?

Minimum order quantities typically start at one complete line or single-machine units depending on configuration. Lead times range from 30 days for standard desktop models to 60+ days for fully customized, high-throughput systems. Refurbished units may ship within 15–20 days.

Do these suppliers support customization?

Yes, most suppliers listed offer customization in feeder types, conveyor widths, software interfaces, and integration with existing factory equipment. High-value customizations include specialized insertion mechanisms for non-standard components and IoT-enabled monitoring systems.

Are CE or ISO certifications commonly available?

While not explicitly stated in all profiles, reputable suppliers adhere to CE standards for electrical safety and EMC compliance. Buyers should request certification documentation directly and verify conformity with regional regulations, especially for deployment in EU or North American facilities.

Can suppliers provide installation and training support?

Many offer remote guidance and documentation. Some provide on-site commissioning services or video-based training modules. For critical deployments, negotiate dedicated technician visits or factory acceptance tests prior to shipment.

Is there a market for refurbished or pre-owned assembly lines?

Yes, select suppliers like Shenzhen Extension Electromechanical and Shenzhen Hongxinteng Technology offer refurbished systems, providing cost-effective entry points for SMEs or pilot production setups. These often include updated controllers and recalibrated subsystems to meet current performance standards.